Production method of agricultural microbial paecilomyces lilacinus for nematode prevention and control

A technology of Paecilomyces lilacinus and its production method, applied in the field of agricultural nematode prevention and control microorganism Paecilomyces lilacinus, which can solve the problem of high cost, affecting the popularization and application of Paecilomyces lilacinus products, and the price of Paecilomyces lilacinus products Advanced issues, to achieve the effect of reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] The production method of the agricultural nematode prevention and control microorganism Paecilomyces lilacinus is to produce the agricultural nematode prevention and control microorganism Paecilomyces lilacinus by using mushroom chaff.

[0017] Shiitake mushrooms are cultivated in most parts of the country, and the total cultivation of shiitake mushrooms is more than 1.5 billion bags. The waste fungus chaff after cultivation of shiitake mushrooms is about 600,000 tons. If 40% of it is used to produce Paecilomyces lilacinus, it can produce Paecilomyces lavender With 240,000 tons of Penicillium products, 240 million mu of farmland can be effectively controlled by Paecilomyces lilacinus products against nematodes, which can increase the total yield of crops in these lands by more than 15%, which can generate huge economic benefits. Using traditional materials such as bran to produce Paecilomyces lilacinus, the cost of materials is high, which is not conducive to popularizat...

Embodiment 2

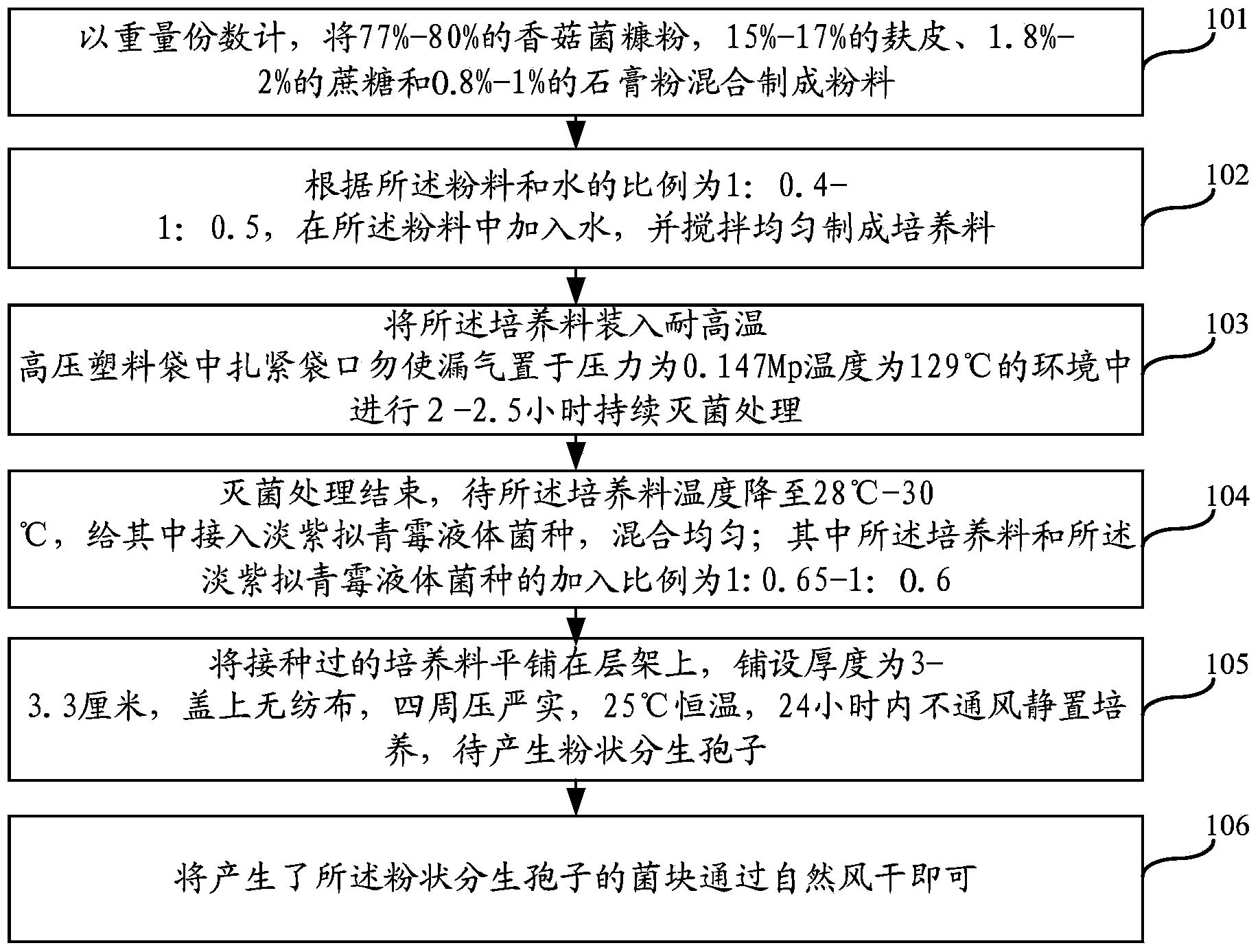

[0019] Based on the above examples, such as figure 1 The method that utilizes shiitake mushroom chaff to produce agricultural nematode prevention and control microorganism Paecilomyces lilacinus specifically comprises the following steps in the present invention shown:

[0020] 101. In parts by weight, mix 77%-80% shiitake chaff powder, 15%-17% bran, 1.8%-2% sucrose and 0.8%-1% gypsum powder to make a powder ;

[0021] 102. According to the ratio of the powder and water being 1:0.4-1:0.5, add water to the powder and stir evenly to make a compost;

[0022] 103. Put the culture material into a high-temperature and high-pressure resistant plastic bag, tie the mouth of the bag tightly to prevent air leakage, place it in a sterilization environment with a pressure of 0.147Mp and a temperature of 129°C, and continue to sterilize for 2-2.5 hours deal with;

[0023] 104. After the sterilization treatment is completed, when the temperature of the culture material drops to 28°C-30°C,...

Embodiment 3

[0037] Based on embodiment 2, the present invention has also been improved as follows:

[0038] In order to use the output of Paecilomyces lilacinus produced by shiitake mushroom chaff powder to be the highest, in parts by weight, the optimal proportioning of the powder is: by 80% shiitake mushroom chaff powder, 17% bran, 2% It is made by mixing sucrose and 1% gypsum powder. When the content of champignon chaff powder is less than 5% than 80%, there is no obvious effect on the yield of Paecilomyces lilacinus; when the content of champignon chaff powder is more than 80%, it is not conducive to the hyphae of Paecilomyces lilacinus Growth and production of powdery conidia.

[0039] The step of packing the culture material into a high temperature and high pressure resistant plastic bag specifically includes:

[0040] The prepared culture material is subpackaged, and the specific loading amount is marked on each subpackaged bag.

[0041] When carrying out the sterilization treat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com