A W-band impatt diode impedance matching pin and preparation method thereof

An impedance matching and diode technology, applied in the field of millimeter-wave semiconductor devices, can solve the problems of high reliability, low operating voltage, small size, etc., and achieve the effect of improving reliability and enhancing heat dissipation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The invention provides a W-band IMPATT diode impedance matching pin:

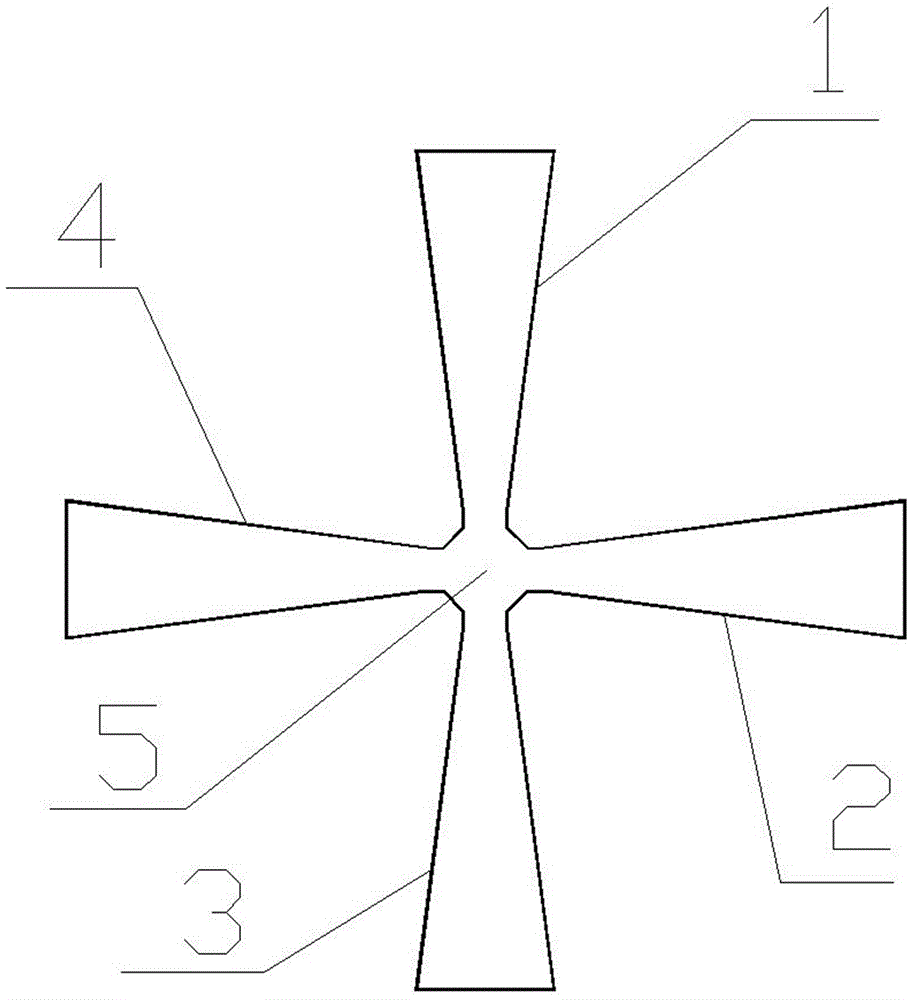

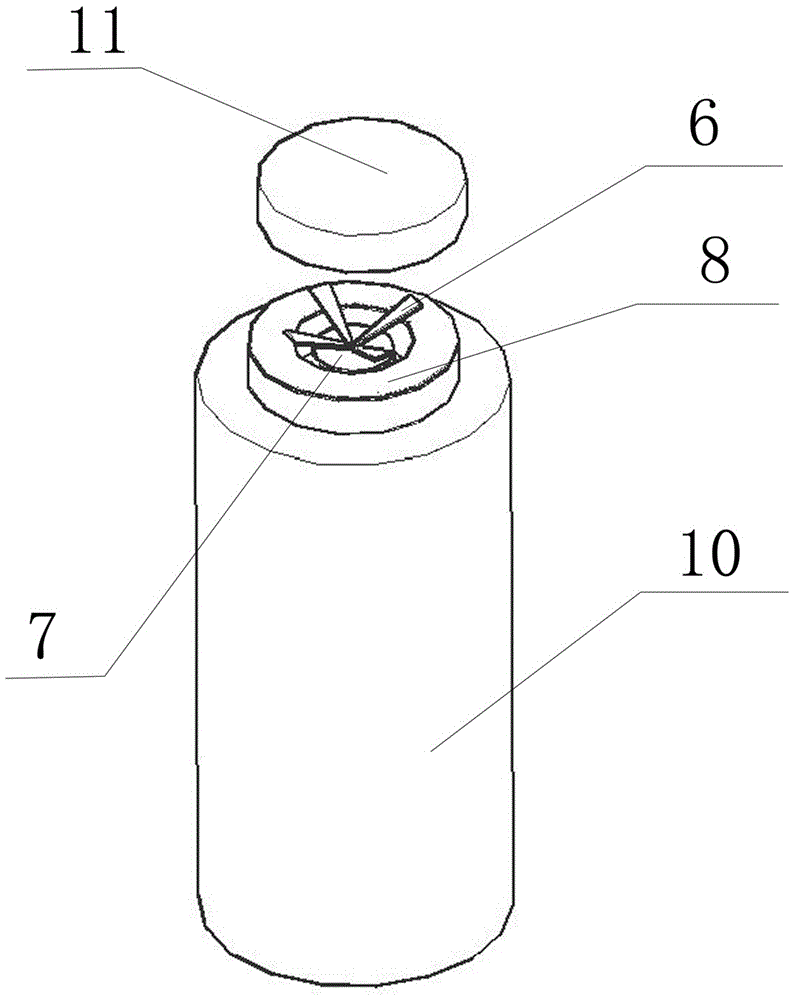

[0020] combine figure 1 and figure 2 As shown, four trapezoidal metal sheets of the same size, the first trapezoidal metal sheet (1), the second trapezoidal metal sheet (2), the third trapezoidal metal sheet (3) and the fourth trapezoidal metal sheet (4) pass through the connecting piece (5) Connect each other to form a cross, with the upper base of each trapezoidal metal sheet facing inward and the lower base facing outward; the connecting sheet (5) is connected to the first trapezoidal metal sheet (1) and the second trapezoidal metal sheet (2) , the third trapezoidal metal sheet (3) and the fourth trapezoidal metal sheet (4) are an integrated structure, which together constitute the impedance matching pin (6); the bottom surface of the connecting sheet (5) and the W-band IMPATT diode (10 ) is fixedly connected to the tube core (7), the lower bottom edge of each trapezoidal metal sheet is fixedly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com