Method of manufacturing multilayer ceramic electronic part

A technology of electronic components and manufacturing methods, which is applied in the manufacture of capacitors, components of fixed capacitors, electrical components, etc., can solve problems such as thinning and cannot be coated smoothly, and achieve the effect of stable electrical characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

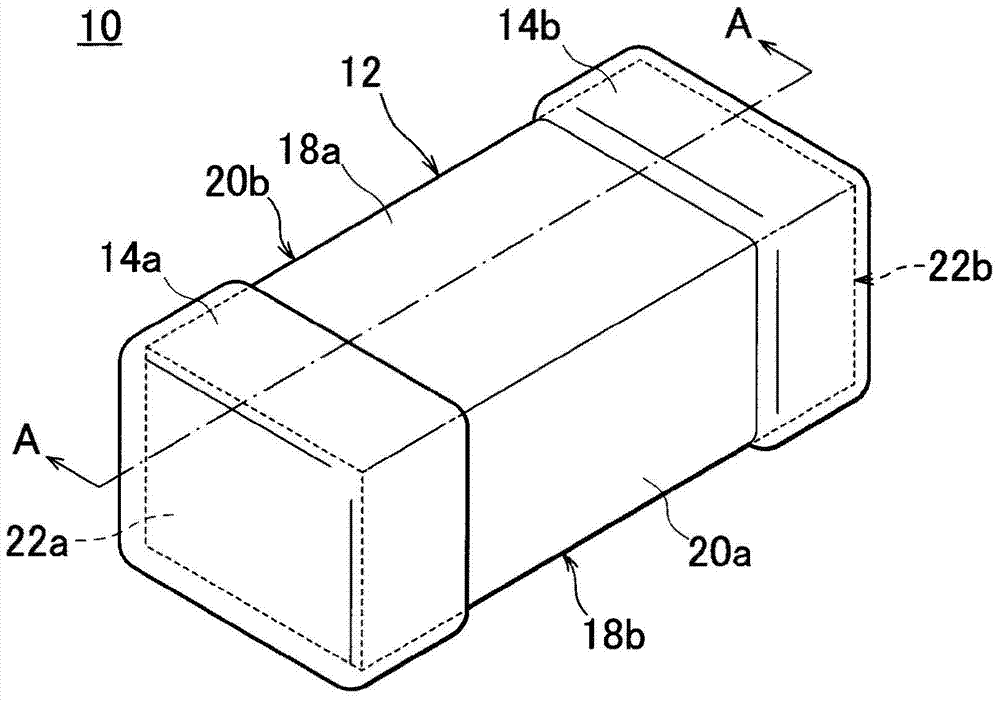

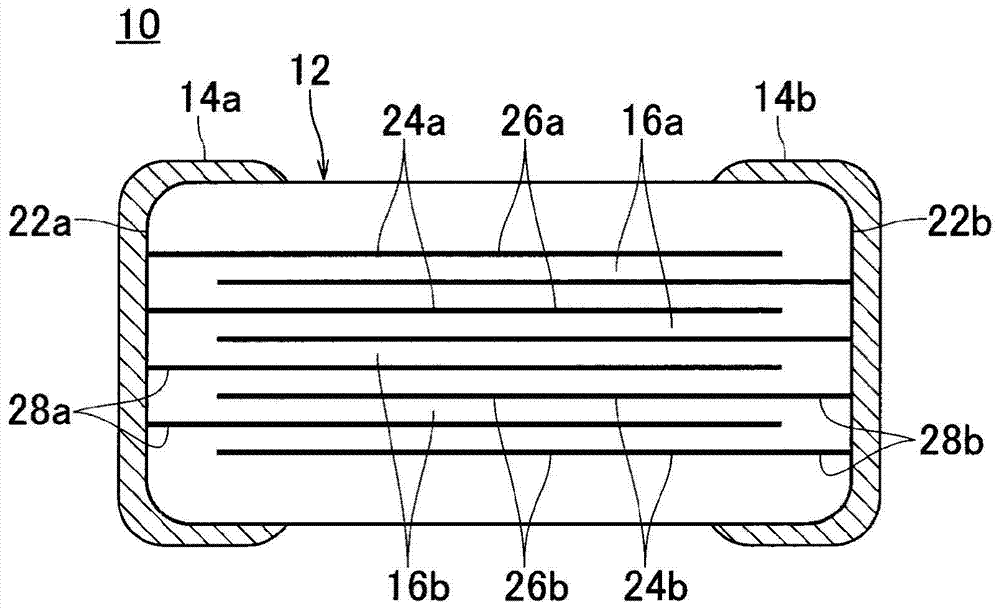

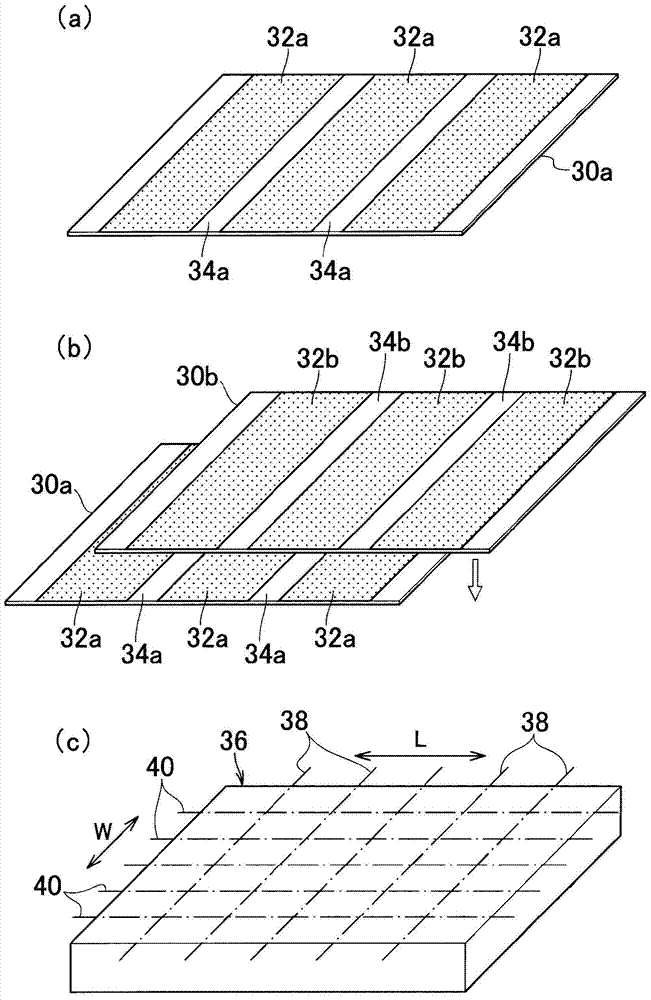

[0100] Next, an example related to a method of manufacturing a laminated ceramic electronic component according to the present invention will be described. The method of manufacturing a laminated ceramic electronic component according to this example is a method of printing stripe-shaped electrodes on a plurality of ceramic green sheets and laminating them, and cutting the laminated body to form a laminated body chip in which the electrodes on the side surfaces are exposed. , and then press this laminated body chip against a metal plate having a groove having an arbitrary volume filled with the paste for an insulator portion, thereby manufacturing a laminated ceramic electronic component.

[0101]In this example, the type of binder, the molecular weight of the binder, the content of the ceramic raw material, and the volume fraction of the ceramics were changed, and the paste for the insulator part in which the viscosity of the paste for the insulator part was changed was trial-...

Embodiment 2

[0153] Next, another embodiment related to the method of manufacturing a laminated ceramic electronic component according to the present invention will be described. The method of manufacturing a laminated ceramic electronic component according to this example is the same as in Example 1: a plurality of ceramic green sheets are printed with electrodes in stripes and laminated, and the laminated body is cut to expose the side surface. A multilayer chip of the electrode of the part is pressed against a metal plate having a groove such as a groove filled with an arbitrary volume of the paste for the insulator part, thereby manufacturing a laminated ceramic electronic component.

[0154] An example of the present invention is shown in a laminated ceramic electronic component in which polyvinyl butyral having a high molecular weight and a large number of hydroxyl groups is used as a binder for ceramic green sheet molding. Paste for insulator parts is prepared by using a solvent inc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com