Fiber composite hydraulic fracturing fluid for shale volume fracturing

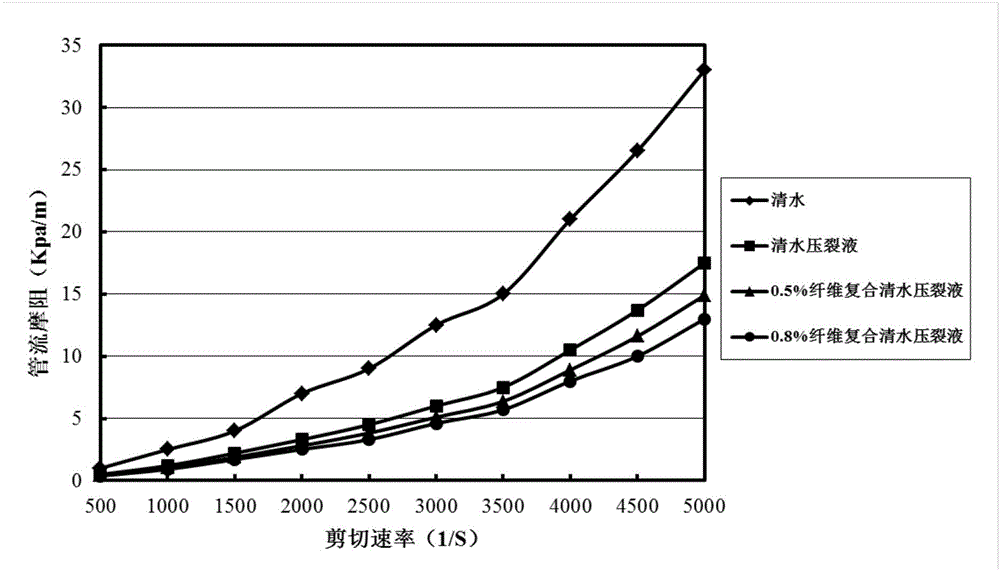

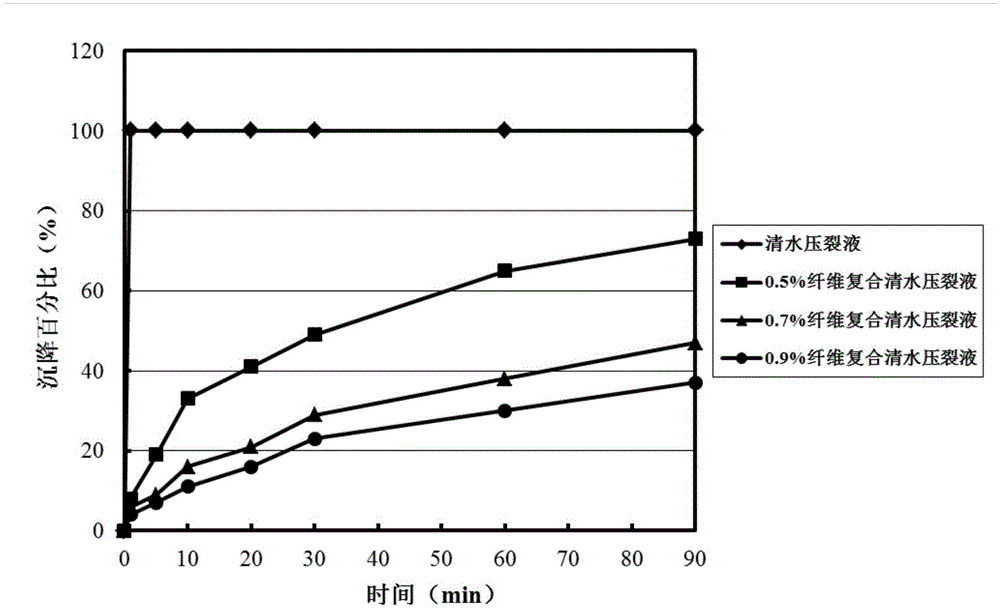

A technology of clear water fracturing fluid and volume fracturing, which is applied in the direction of drilling compositions, chemical instruments and methods, and can solve problems such as poor formation compatibility, increased pipe string friction, and weak sand-carrying capacity. Achieve good thermodynamic and chemical stability, reduce pipe string friction and improve suspended sand performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0035] In a fiber composite clear water fracturing fluid formula for shale volume fracturing, the clear water fracturing fluid includes, by weight percentage: drag reducer, 0.1%; anti-swelling agent, 1%; long-acting clay stabilizer agent, 1%; fungicide, 0.06%; scale inhibitor, 0.005%; surfactant, 0.3%; the balance is water. The fiber is nano-SiO 2 Composite fibers.

[0036] The preparation process is as follows: take 975.35 grams of water and put it in a sterile mixer, add 1 gram of drag reducer (anionic polyacrylamide drag reducer product XT-65B, molecular weight is about 10 million, active ingredient 35%) 1 gram, Long-acting clay stabilizer (CS-2) 10 grams, anti-swelling agent (KCl) 10 grams, scale inhibitor (organophosphate XT-97) 0.05 grams, compound fungicide (glutaraldehyde 0.51 grams, dodecyl Dimethyl benzyl ammonium chloride (0.09 g) 0.6 g, stir for 1 minute, then add 3 g of surfactant (drainage aid, non-ionic fluorocarbon surfactant SF-2), stir for 30 seconds to mak...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com