High-strength wear-resistant corrosion-resistant antimagnetic stainless steel

A high-strength, stainless steel technology, applied in the field of alloy materials, can solve problems such as strength and wear resistance not meeting the requirements of use, insufficient corrosion resistance, and affecting the appearance quality of the drum.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

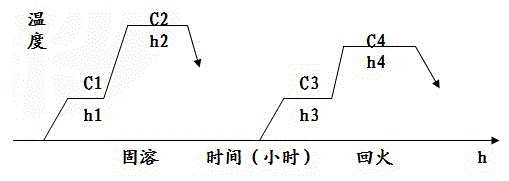

Embodiment 1

[0059] 1. Processing of anti-corrosion and anti-magnetic steel: Add steel scrap and pig iron into the melting furnace to heat up and melt. The melting furnace should be an intermediate frequency induction furnace. The melting temperature is generally around 1450°C-1550°C. Add nickel plate, ferromanganese, ferrochromium, ferromolybdenum, ferrovanadium and ferroniobium in sequence, and the diameter of the material block is preferably 50-80mm. The mass percentages of the above chemical components are controlled as follows: C: 0.25%, Si: 0.70%, Mn: 0.50%, Cr: 17.00%, Ni: 11.00%, Mo: 2.00%, V: 0.45%, Nb: 0.10%. After melting, when the furnace temperature reaches 1550-1580°C, deoxidize, dehydrogenate, and denitrify. The deoxidizer is made of aluminum wire and Si-Ca alloy. -5mm is appropriate) Ti:0.13%, the metal liquid surface is covered with a covering agent at this time, and the outside air is cut off, the rare earth ferrosilicon alloy is added to the ladle (the diameter is prefer...

Embodiment 2

[0064] 1. Processing of anti-corrosion and anti-magnetic steel: Add steel scrap and pig iron into the melting furnace to heat up and melt. The melting furnace should be an intermediate frequency induction furnace. The melting temperature is generally around 1450°C-1550°C. Add nickel plate, ferromanganese, ferrochromium, ferromolybdenum, ferrovanadium and ferroniobium in sequence, and the diameter of the material block is preferably 50-80mm. The mass percentages of the above chemical components are controlled as follows: C: 0.35%, Si: 1.00%, Mn: 1.50%, Cr: 19.00%, Ni: 13%, Mo: 2.5%, V: 0.55%, Nb: 0.15%, melting After cleaning, when the furnace temperature reaches 1550-1580°C, deoxidation, dehydrogenation, and denitrification are required. The deoxidizer is made of aluminum wire and Si-Ca alloy. -5mm is appropriate) Ti: 0.18%, the metal liquid surface is covered with a covering agent at this time to cut off the outside air, rare earth ferrosilicon alloy is added to the ladle (th...

Embodiment 3

[0069] 1. Processing of anti-corrosion and anti-magnetic steel: Add steel scrap and pig iron into the melting furnace to heat up and melt. The melting furnace should be an intermediate frequency induction furnace. The melting temperature is generally around 1450°C-1550°C. Add nickel plate, ferromanganese, ferrochromium, ferromolybdenum, ferrovanadium and ferroniobium in sequence, and the diameter of the material block is preferably 50-80mm. The mass percentages of the above chemical components are controlled as follows: C: 0.32%, Si: 0.85%, Mn: 1.20%, Cr: 18.50%, Ni: 12.00%, Mo: 2.32%, V: 0.50%, Nb: 0.13%. After melting, when the furnace temperature reaches 1550-1580°C, deoxidation, dehydrogenation, and denitrification are required. The deoxidizer is made of aluminum wire and Si-Ca alloy. 3-5mm is appropriate) Ti: 0.15%, the metal liquid surface is covered with a covering agent at this time to cut off the outside air, rare earth ferrosilicon alloy is added into the ladle (the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com