Regenerative industrial furnace and convection radiation wall thereof

An industrial furnace and regenerative technology, applied in furnaces, furnace components, lighting and heating equipment, etc., can solve the problem of uneven resistance of different airflow channels, uneven distribution of flame and high-temperature furnace gas, and poor mixing of fuel and combustion-supporting air To achieve the effect of improving fluidity and medium mixing uniformity, improving heat transfer effect, improving production efficiency and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

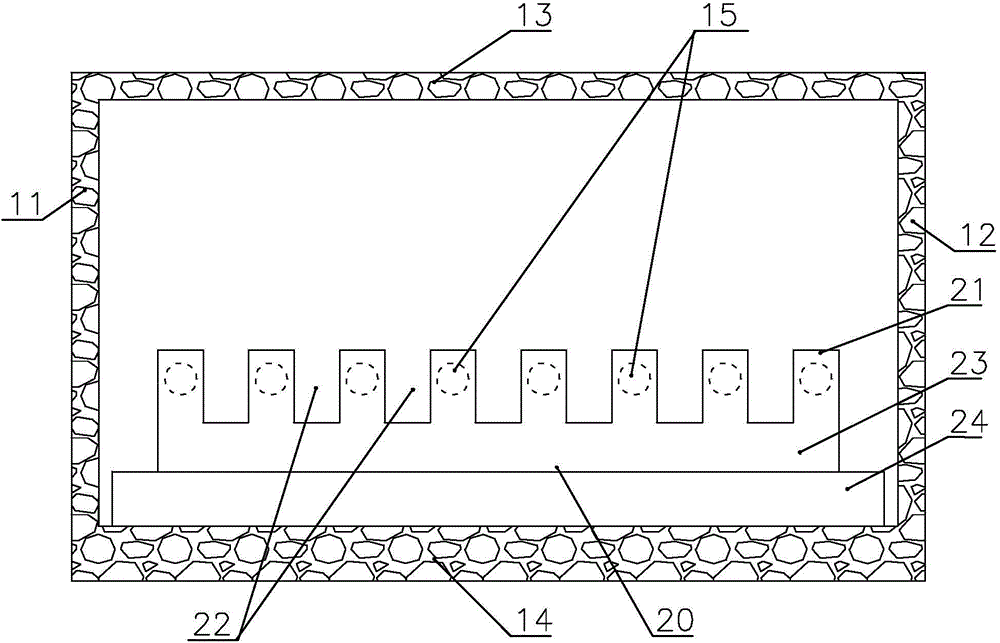

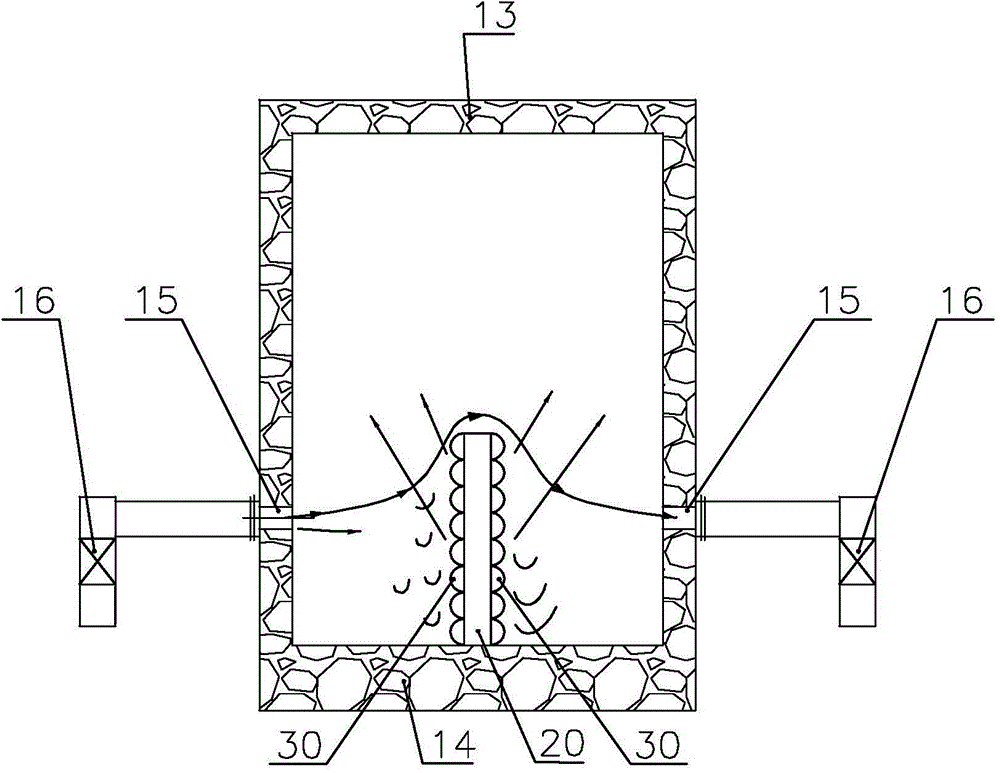

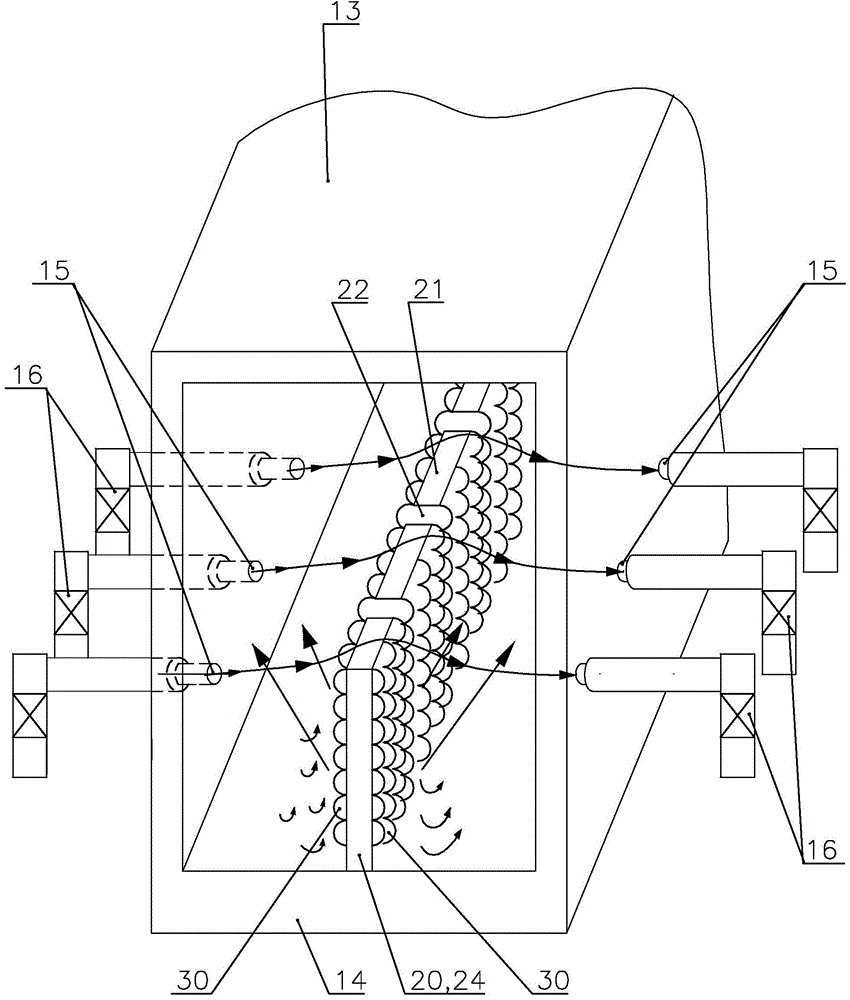

[0029] Such as Figure 1-6 , which are structural schematic diagrams of different viewing angles of the embodiment of the regenerative industrial furnace and the convective radiation wall of the present invention, respectively. The regenerative industrial furnace embodiment includes a front end 11 of a furnace body, a rear end 12 of a furnace body, a furnace top 13, a furnace bottom 14, and two sides each having eight furnace ports 15, and the furnace ports on both sides correspond one by one. The furnace openings on the sides are all connected with waste heat regenerators 16; a convective radiation wall 20 is provided in the middle of the furnace width between the regenerative industrial furnace 2 sides; direction.

[0030] The convective radiation wall 20 is made of high temperature resistant material, and it is located in the middle of the furnace width of the regenerative industrial furnace that has more than two furnace ports on both sides and the furnace ports on both s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com