Aluminum Alloy Flat Ingot Ultrasonic Testing Device and Flaw Detection Method

A detection device and ultrasonic technology, which are used in measurement devices, analysis of solids using sonic/ultrasonic/infrasonic waves, and material analysis using sonic/ultrasonic/infrasonic waves. methods, uneven force application, etc., to avoid the cleaning work of couplant, improve the efficiency of inspection work, and reduce fatigue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

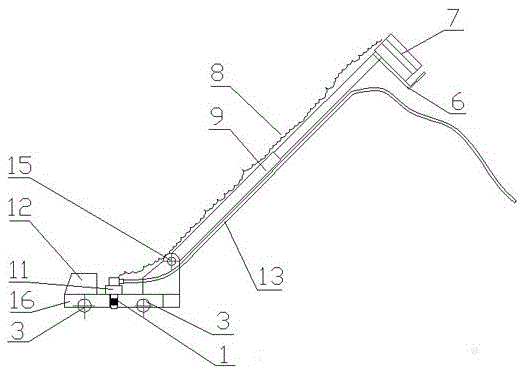

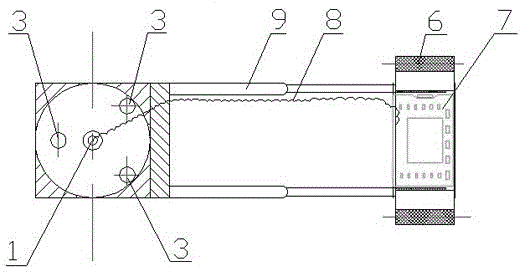

[0028] Such as figure 1 with figure 2 As shown,.

[0029] The ultrasonic detection device of the present invention is a water spray type straight probe type, and its structure and connection mode are:

[0030] Base 16 is provided with balance weight 12, three support balls 3, water spray type straight probe 1 and steering shaft 15; steering shaft 15 is connected with connecting rod 9, and one end of connecting rod 9 is provided with ultrasonic equipment bracket 6, portable The ultrasonic device 7 is installed on the ultrasonic device bracket 6; the portable ultrasonic device 7 is connected with the water spray straight probe 1 through the probe line 8; the water spray straight probe 1 is fixed on the base 16 through the water switch 11; The probe 1 is provided with a water inlet, which communicates with the water pipe 13;

[0031] Its working principle and exploration method are:

[0032] Put the ultrasonic detection device on the upper surface of the aluminum alloy ingot...

Embodiment 2

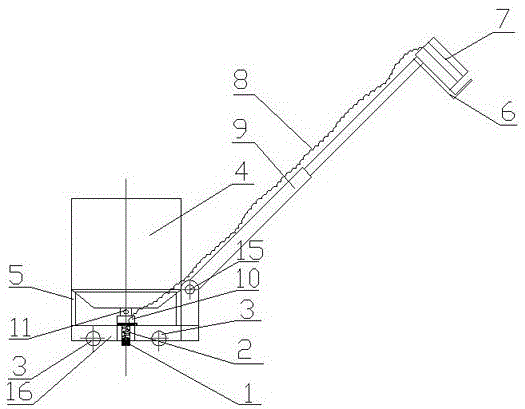

[0034] Such as image 3 As shown, the ultrasonic detection device of the present invention is a contact type straight probe type, and its structure and connection mode are:

[0035] Base 16 is provided with three support balls 3, contact straight probe 1, water storage tank 4, water storage tank support 5, steering shaft 15 and balance weight 12; contact straight probe 1 has spring 2 inside, and spring can make contact type The straight probe 1 is close to the surface of the workpiece to be tested; a water application device 10 is provided above the contact type straight probe 1, a water switch 11 is provided between the water application device 10 and the water storage tank 4, and a valve is provided on the water application device 10; the steering shaft 15 is connected with connecting rod 9, and one end of connecting rod 9 is provided with ultrasonic equipment support 6, and portable ultrasonic equipment 7 is installed on the ultrasonic equipment support 6; Portable ultrason...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com