Coal-mine gas movement detection data processing method of mine Internet of Things

A technology for coal mine gas and data processing, which is applied in mining equipment, mining equipment, earth-moving drilling, etc., can solve problems such as surge in workload and inability to meet moving points, and achieve improved reliability, wide practicability, and simplified adjustment. effect of the problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

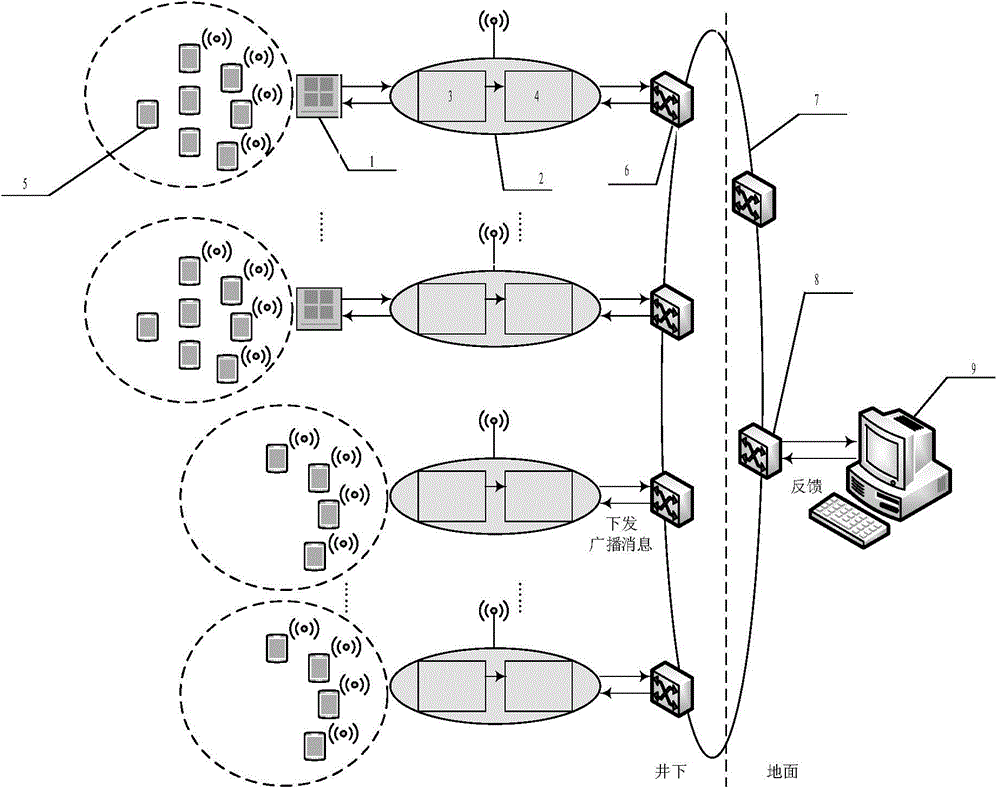

[0019] Such as figure 1 As shown, the coal mine gas mobile detection data processing method of the mine Internet of Things utilizes the mine Internet of Things architecture, and a wireless access point 2 is installed next to each fixed gas detector 1, and the wireless access point 1 and the fixed gas detector 2 use a short Wired connection, shared power cord. The wireless access point needs to be pre-burned with a simple sensor preprocessing unit 3 and a sensor determination unit 4 functional program. When a worker wearing a smart miner's lamp with gas detection function walks underground, when he passes by a fixed gas detector, the detected mobile gas monitoring data is transmitted to the wireless access point connected to the fixed gas detector. The wireless access point simultaneously collects the data detected by the fixed gas detector and the data detected by the mobile gas detector 5 passing through the wireless access point.

[0020] The switch 8 uploads to the g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com