Servo Closed-loop Control System of Plate Laminated Plug Oil Cylinder in Freeze Dryer

A servo closed-loop and control system technology, applied in the direction of electrical program control, sequence/logic controller program control, etc., can solve the problems of oil cylinder sliding, poor precision of plate positioning control, hydraulic shock, etc., and reduce oil circuit structure , Stable layer positioning and improved control accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

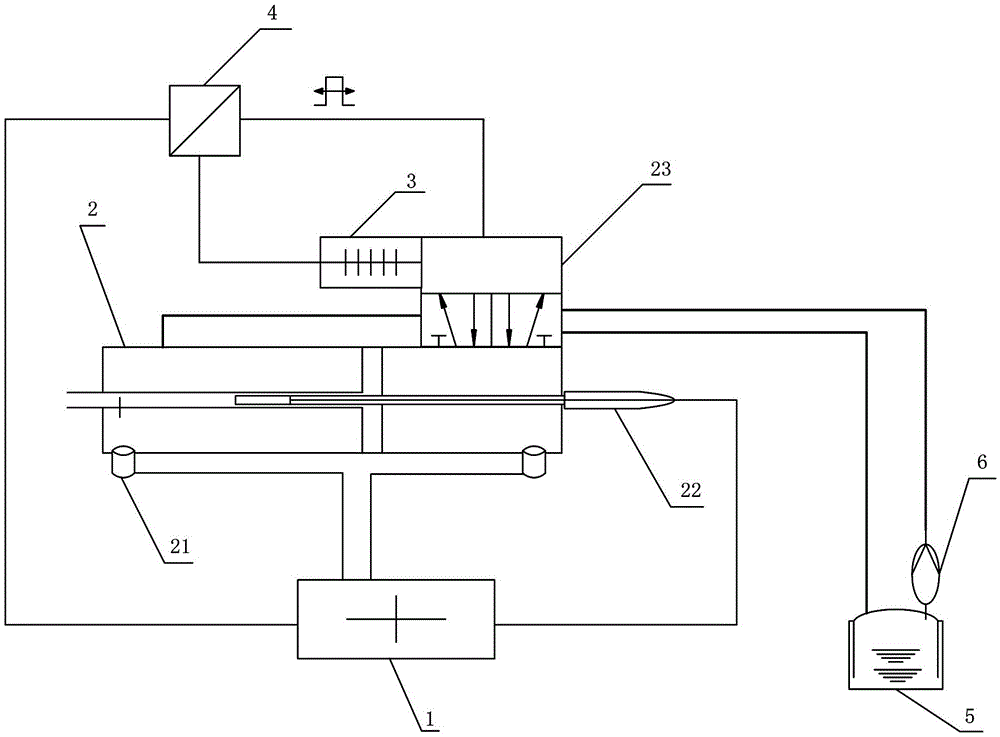

[0021] Such as figure 1 As shown, it is a specific embodiment of the servo closed-loop control system of the plate lamination plug cylinder of the freeze dryer of the present invention. The servo closed-loop control system includes a control component, a servo proportional valve 23, a servo proportional valve controller 4, and a The position detection component on the valve 23, the pressure detection component and the displacement detection component installed on the plate lamination plug cylinder 2 of the freeze dryer;

[0022] The pressure detection component detects the pressure signal of the plate lamination plug cylinder 2 of the freeze dryer; the displacement detection component detects the displacement signal of the freeze dryer plate laminate plug cylinder 2; the position detection component detects the actual opening signal of the serv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com