Reutilization method and grating line recovery method of defective monocrystalline silicon battery sheet after sintering

A technology for monocrystalline silicon cells and silicon wafers, applied in circuits, electrical components, semiconductor devices, etc., can solve the problems of unsuitable monocrystalline silicon cells, achieve the convenience of overall recycling, improve the qualified rate of finished products, and reduce enterprise costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

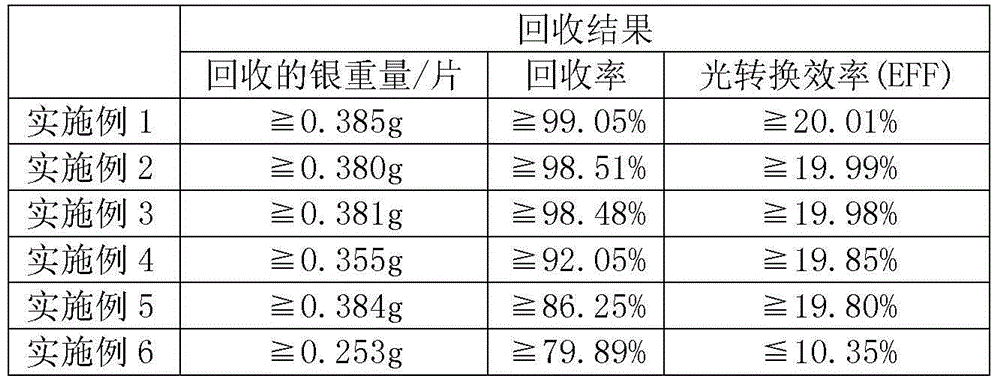

Examples

Embodiment 1

[0037] Embodiment 1: A method for reusing unqualified finished photovoltaic monocrystalline silicon cells of 156*156, the method specifically includes the following steps:

[0038] 1) Pickling step: Put 156*156 unqualified finished photovoltaic monocrystalline silicon cells into 10% HF solution, soak for 10 minutes at 25°C, take out pure water, clean them, dry them, and remove the fallen precious metals. Grid line for recovery and weighing.

[0039] 2) The step of removing the surface doping layer: at 16°C, use 40 parts by volume of HF with a mass concentration of 40%, 140 parts by volume of HNO3 with a mass concentration of 65%, and 70 parts by volume of water for 2 minutes. The corrosion thickness of the silicon wafer surface was controlled at 1.5 μm, and then rinsed with pure water; then the residual acid solution was removed with KOH with a mass concentration of 48%, and rinsed with pure water; Rinse with water and let dry.

[0040] 3) Perform secondary processing on the...

Embodiment 2

[0041] Embodiment 2: A method for reusing unqualified finished photovoltaic monocrystalline silicon cells of 125*125, the method specifically includes the following steps:

[0042] 1) Pickling step: Put 125*125 unqualified finished photovoltaic monocrystalline silicon cells into 15% HF solution, soak for 15 minutes at 30°C, take out pure water, clean them, and dry them to remove the fallen precious metals. Grid line for recovery and weighing.

[0043] 2) The step of removing the surface doping layer: at 14°C, use 30 parts by volume of HF with a mass concentration of 30%, and 130 parts by volume of HNO with a mass concentration of 60% 3 , 60 parts by volume of water mixed acid treatment for 5 minutes, the thickness of the corrosion amount on the surface of the silicon wafer is controlled at 1.0 μm, and then rinsed with pure water; then use KOH with a mass concentration of 40% to remove the residual acid solution and rinse with pure water; Then use HF with a mass concentration ...

Embodiment 3

[0045] Embodiment 3: a kind of 125*125 reutilization method of unqualified finished photovoltaic monocrystalline silicon cells, the method specifically comprises the following steps:

[0046] 1) Pickling step: put 125*125 unqualified finished photovoltaic monocrystalline silicon cells into 40% HF solution, soak for 3 minutes at 20°C, take out pure water, clean them, dry them, and remove the fallen precious metals Grid line for recovery and weighing.

[0047] 2) The step of removing the surface doping layer: at 18°C, use 50 parts by volume of HF with a mass concentration of 50%, 150 parts by volume of HNO3 with a mass concentration of 70%, and 80 parts by volume of water for 0.5 minutes, The thickness of the corrosion amount on the surface of the silicon wafer is controlled at 2.0 μm, and then rinsed with pure water; then the residual acid solution is removed with KOH with a mass concentration of 50%, and rinsed with pure water; then the red water is cleaned with HF with a mass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com