Flip-chip light-emitting diode with symmetrical electrodes and its preparation method

A technology of light-emitting diodes and symmetrical electrodes, applied in circuits, electrical components, semiconductor devices, etc., can solve problems that affect the stability and welding yield of flip-chip light-emitting diodes, P and N-type solder joints are short-circuited, and chips do not emit light. Achieve good soldering contact, improve uniformity, and improve yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

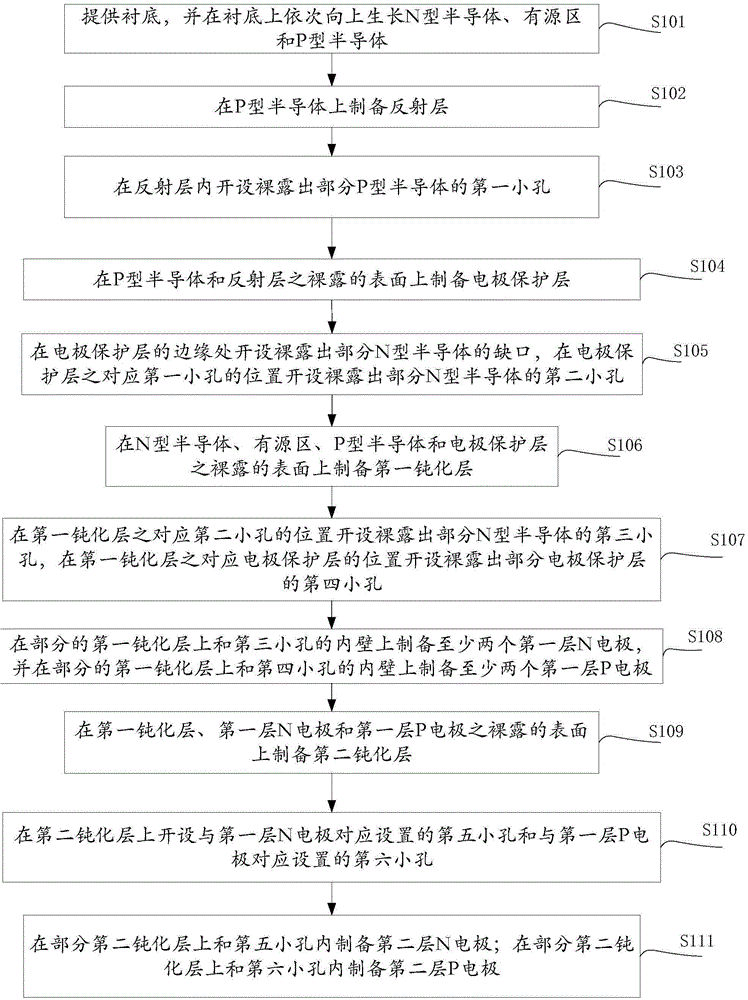

[0065] This embodiment provides a method for manufacturing a flip-chip light-emitting diode with symmetrical electrodes. refer to figure 1 , the method includes:

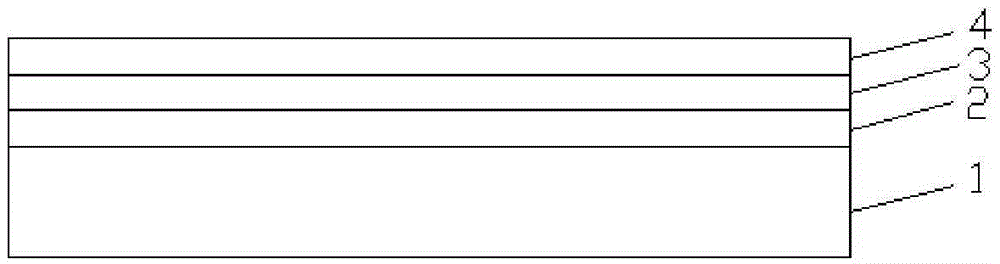

[0066] In step S101, a substrate 1 is provided, and an N-type semiconductor 2, an active region 3 and a P-type semiconductor 4 are sequentially grown up on the substrate 1 (see Picture 1-1 );

[0067] In this embodiment, the substrate 1 may be a substrate formed of any one of sapphire, diamond, silicon and gallium arsenide. It can be understood that the growth of the N-type semiconductor 2 , the active region 3 and the P-type semiconductor 4 can be realized by vapor deposition by MOCVD (Metal-organic Chemical Vapor Deposition) equipment.

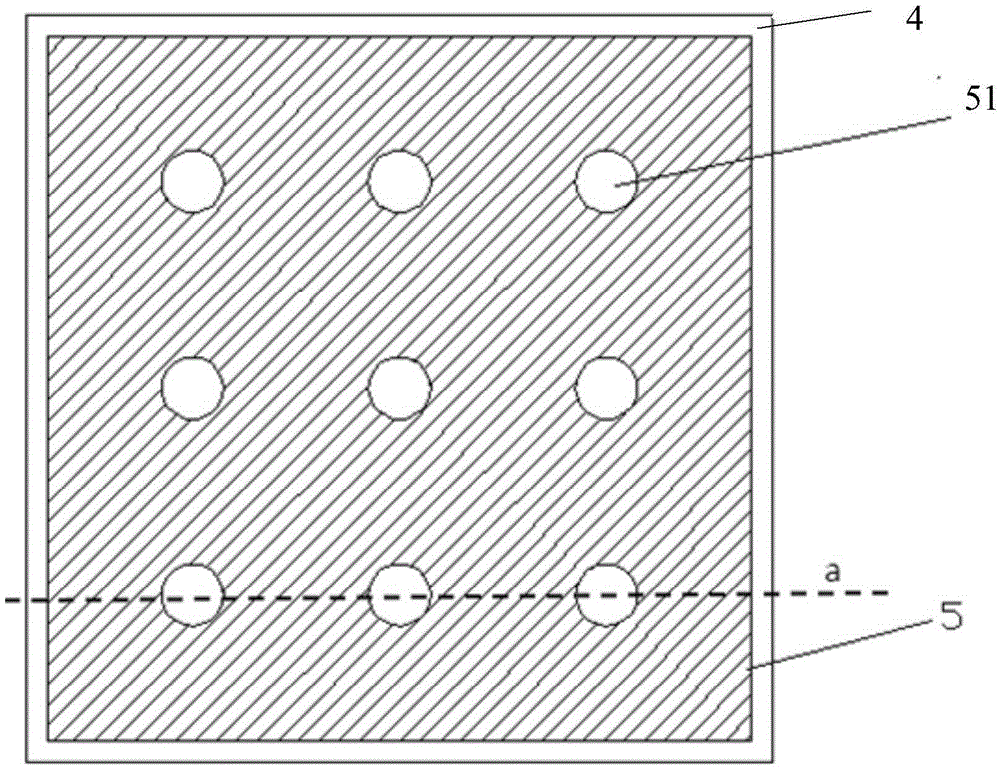

[0068] Step S102, preparing a reflective layer 5 on the P-type semiconductor 4 (see diagram 2-1 with Figure 2-2 );

[0069] It should be noted that the reflective layer 5 may be a film with high reflectivity and high conductivity. The reflective layer 5 is located on the...

Embodiment 2

[0108] This embodiment provides a flip-chip light emitting diode with symmetrical electrodes. see Figure 10-2 with Figure 10-3 , the flip-chip LED consists of:

[0109] Substrate 1, N-type semiconductor 2, active region 3, P-type semiconductor 4, light-reflecting layer 5 and electrode protection layer 6 grown upwards on the substrate 1 in sequence, and a plurality of first small holes are opened on the light-reflecting layer 5 51, the first small hole 51 extends from the reflective layer 5 to the P-type semiconductor (see diagram 2-1 with Figure 2-2 );

[0110] The electrode protection layer 6 covers the exposed surface (i.e. the upper surface and the side wall) of the reflective layer 5, and the electrode protection layer 6 is provided with a plurality of second small holes 61, and the second small holes 61 are connected with the first small holes 51. Correspondingly arranged, the second small hole 61 extends from the electrode protection layer 6 to the N-type semico...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com