Control system of driving power supply for pulsed fiber laser based on cpld

A fiber laser and driving power technology, applied in excitation methods/devices, etc., can solve the problems of real-time acquisition and control of optical power, and achieve the effects of sensitive control, low cost, and fast feedback

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The objects and functions of the present invention and methods for achieving the objects and functions will be clarified by referring to the exemplary embodiments. However, the present invention is not limited to the exemplary embodiments disclosed below; it can be implemented in various forms. The essence of the description is only to help those skilled in the relevant art comprehensively understand the specific details of the present invention.

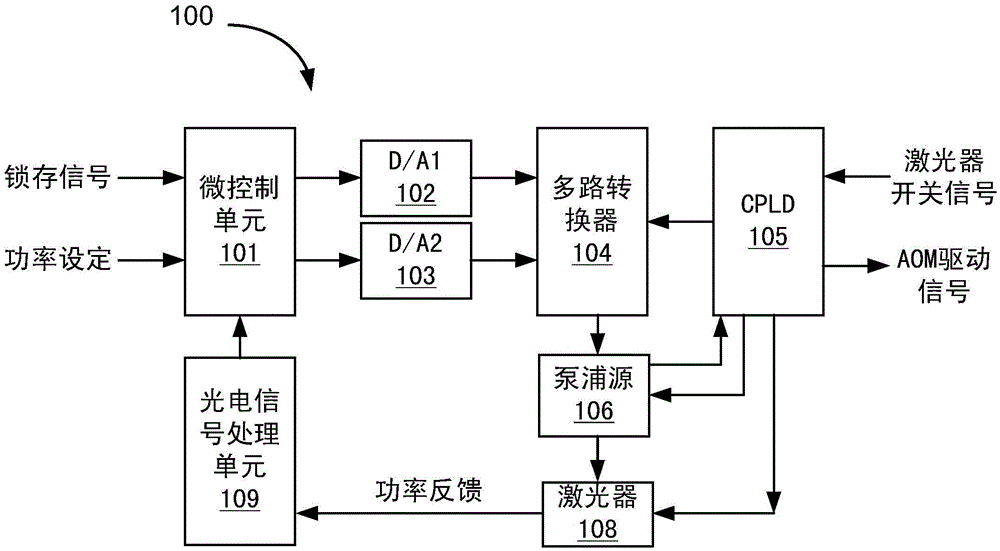

[0024] figure 1 A system block diagram of a CPLD-based pulsed fiber laser drive power control system according to the present invention is schematically shown. The drive power control system 100 according to the present invention comprises a micro control unit 101, a first digital-to-analog converter 102, a second digital-to-analog converter 103, a multiplexer 104, a CPLD control chip 105, a pumping source 106 of a laser 108, Pulse fiber laser 108 and photoelectric signal processing unit 109.

[0025] The micro control uni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com