Microelectromechanical sound detection apparatus and method for producing such an apparatus

A detection device and micro-electromechanical technology, applied in microelectronic microstructure devices, measurement devices, electrical devices, etc., can solve the problems of expensive manufacturing, microphone damage, etc., and achieve reduced manufacturing costs, low costs, and reduced thickness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

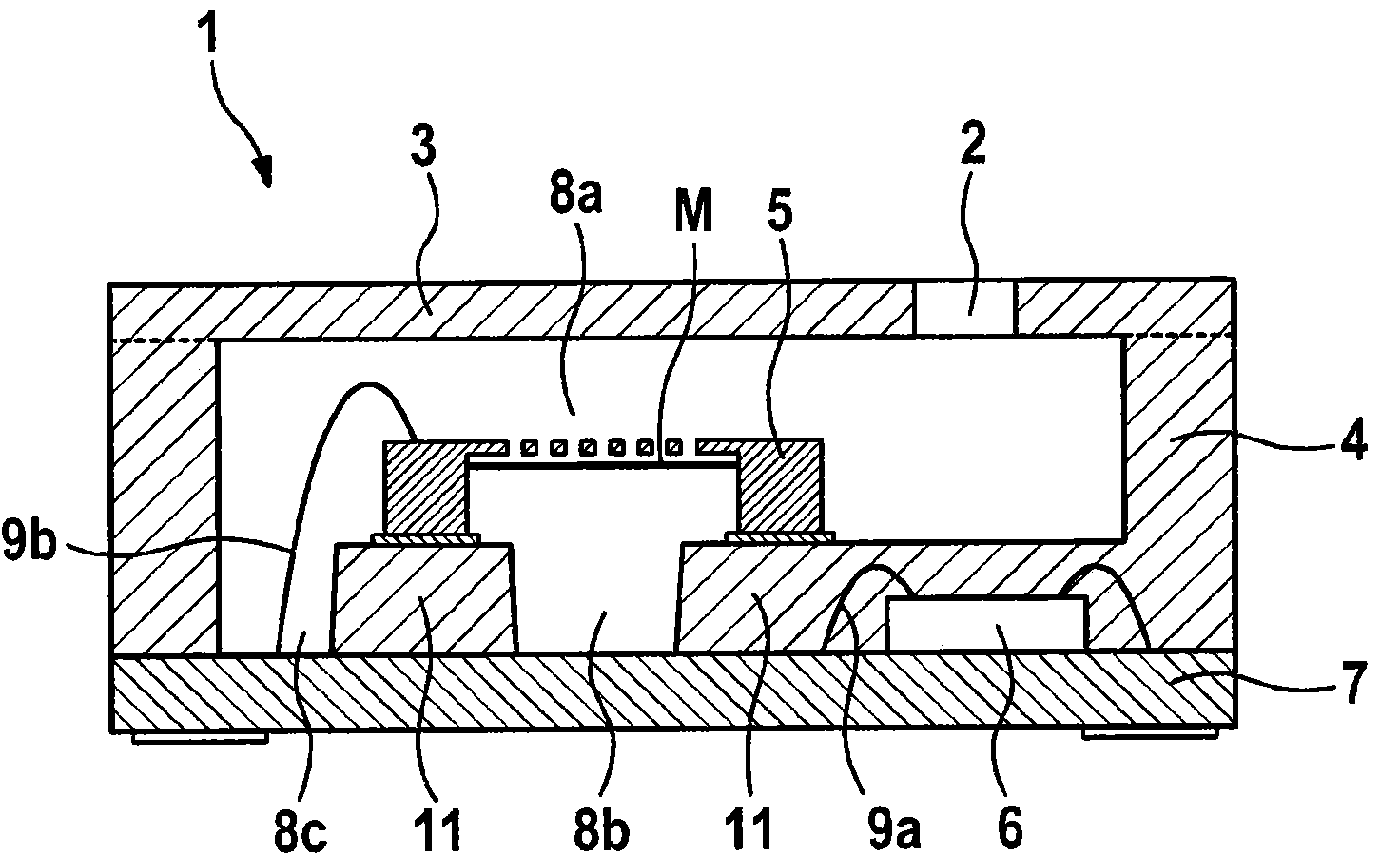

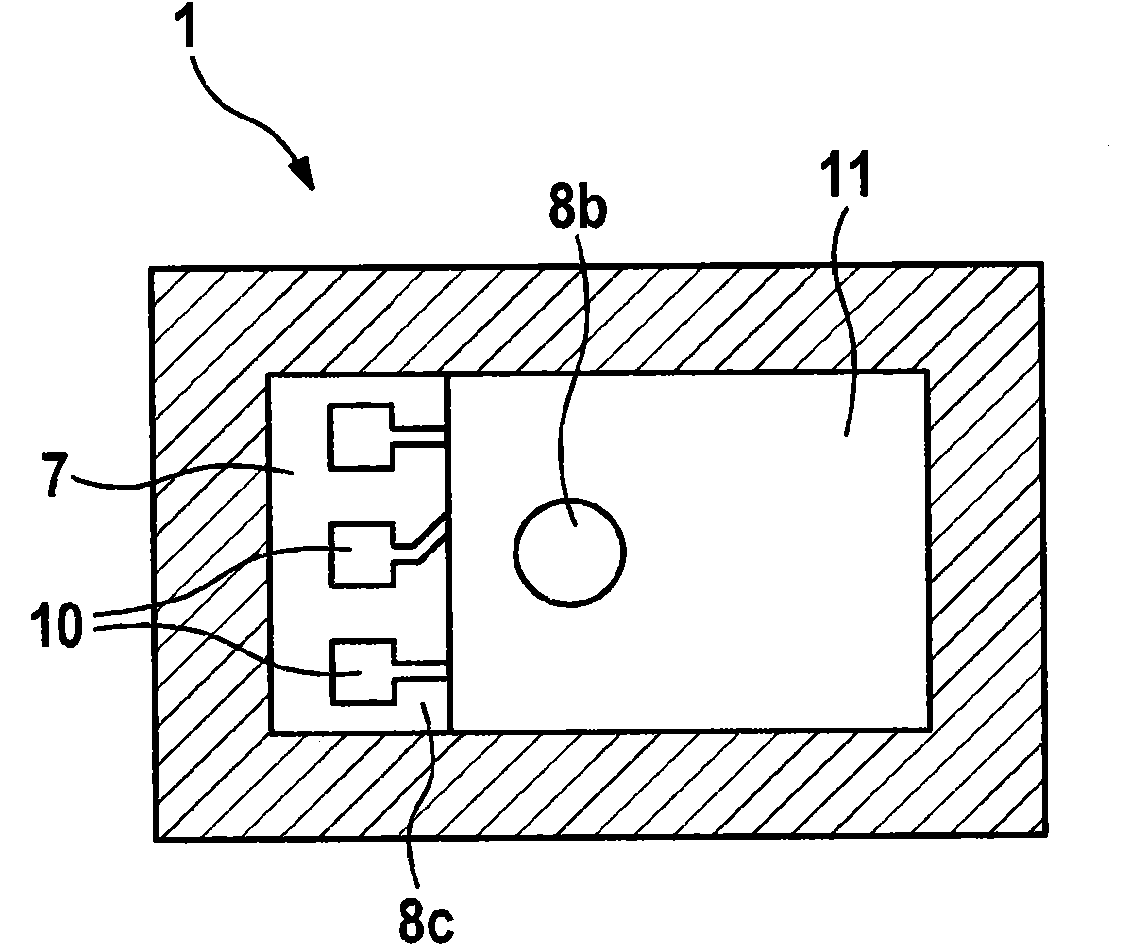

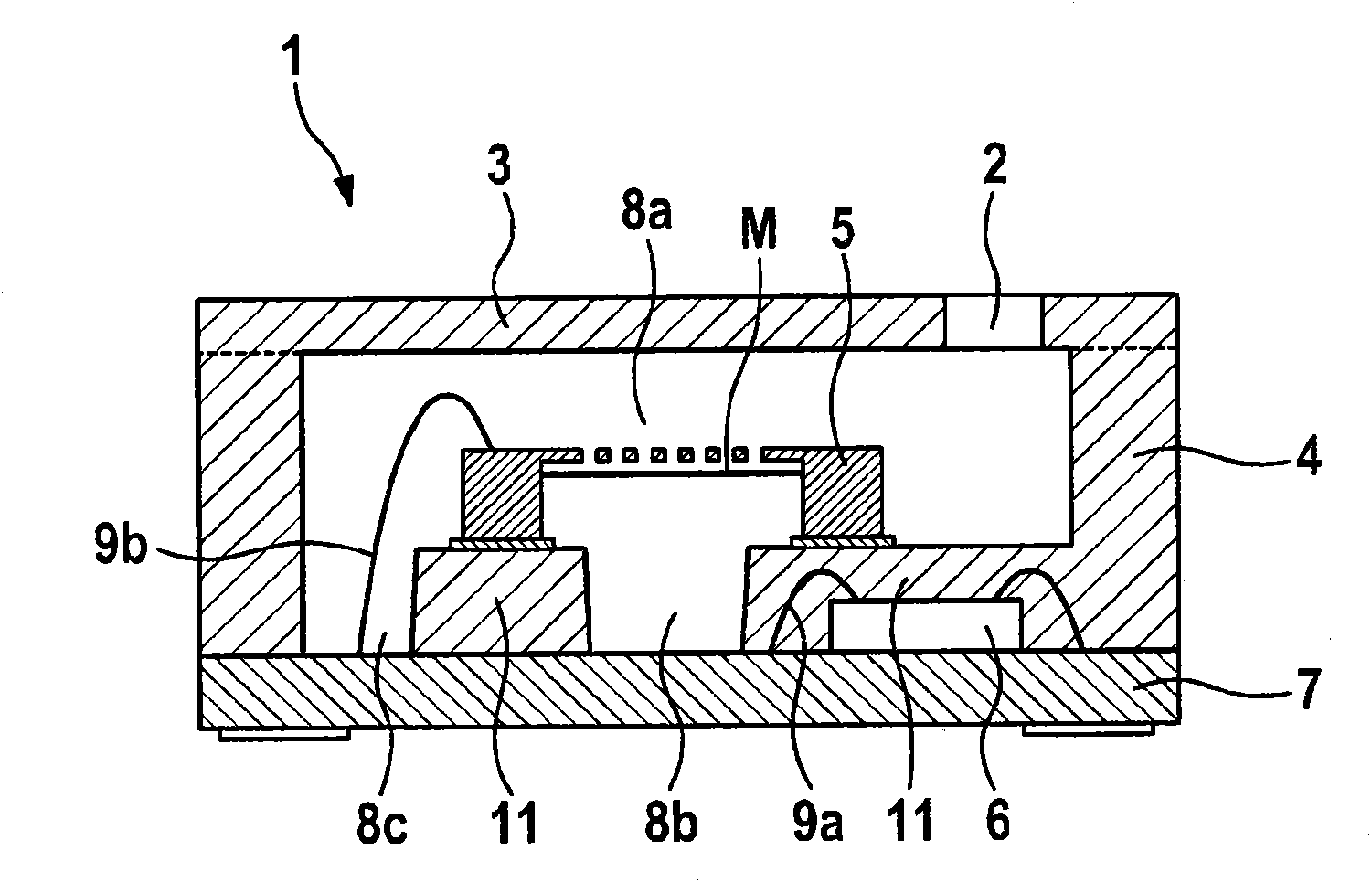

[0029] figure 1 A microelectromechanical sound detection device according to a first embodiment is shown in cross-section in schematic form.

[0030] exist figure 1 In the reference numeral 1 denotes a microelectromechanical sound detection device. The MEMS sound detection device includes a land grid array circuit board 7 as a substrate. An application-specific integrated circuit 6 is arranged on the planar grid array circuit board 7, which is connected to the planar grid array circuit board 7 by wire bonds 9a for electrical contact. The application specific integrated circuit 6 is housed in a part of the wall of the moulded housing 4 . The molded housing 4 is also fixedly connected to the planar grid array circuit board 7 . The molded housing 4 is essentially hollow on the inside and has a cover 3 in the upper region of the molded housing 4 . at the envisaged vertical midline (at figure 1 On the right side from top to bottom) in the cover plate 3 is arranged an opening ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com