Medicament microsphere and preparation method thereof

A technology of drugs and microspheres, applied in the directions of drug combination, drug delivery, pharmaceutical formulation, etc., can solve the problem of no celecoxib sustained-release hollow microspheres and immediate-release microspheres, etc., and achieve low cost and high encapsulation efficiency. , the effect of small particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

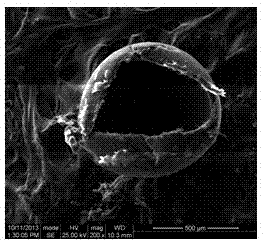

[0033] Preparation: according to the prescription in Table 1, dissolve celecoxib and EC in 20 mL of a mixed solvent of ethyl acetate and ether (3:1) as the dispersed phase; 0.5% poloxamer-188 solution as the continuous phase; Add it into the continuous phase for emulsification under the condition of stirring, raise the temperature to 30°C, stir to remove the organic solvent, filter with suction, wash with distilled water, and dry to obtain celecoxib microspheres.

[0034] Table 1 Preparation of celecoxib microspheres with different EC viscosity formulations

[0035]

[0036] The celecoxib microspheres prepared in Example 1 were evaluated for quality, and the results are shown in Table 2:

[0037] Table 2 Effect of EC viscosity on celecoxib microspheres

[0038]

Embodiment 2

[0040] Preparation: Dissolve celecoxib, release modifier and EC in ethyl acetate and ether (10:

[0041] 1) Use 10mL of the mixed solvent as the dispersed phase; 0.5% poloxamer-188 solution as the continuous phase; add the dispersed phase to the continuous phase for emulsification under stirring conditions, raise the temperature to 30°C, stir to remove the organic solvent, suction filter, Washing with distilled water and drying to obtain celecoxib sustained-release microspheres.

[0042] Table 3 Preparation of different formulations of celecoxib microsphere release modifier

[0043]

[0044]

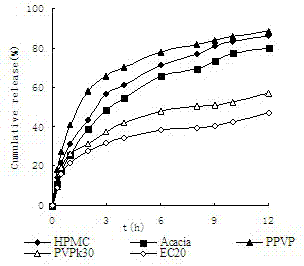

[0045] The celecoxib sustained-release microspheres prepared in Example 2 were evaluated for quality, and the results are shown in Table 4. Among them, the celecoxib sustained-release microspheres prepared with PPVP as the release regulator had the highest encapsulation efficiency.

[0046] Table 4 Effect of release modifiers on celecoxib microspheres

[0047]

[0048] The cel...

Embodiment 3

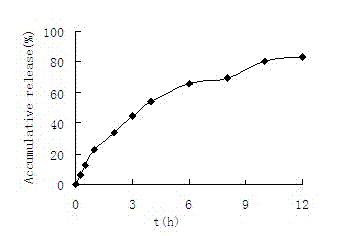

[0050] Dissolve EC20, CXB, and PVPP in 40 mL of a mixed solvent of ethyl acetate and ether (5:1) to make corresponding concentrations of 60 mg·mL -1 , 60mg·mL -1 and 2% solution as the dispersed phase; 0.5% poloxamer-188 solution as the continuous phase; add the dispersed phase to the continuous phase for emulsification under high-speed stirring conditions, raise the temperature to 30°C, stir to remove the organic solvent, filter and wash , dry to get celecoxib microspheres. The quality of the celecoxib microspheres prepared in Example 3 was evaluated, and the results are shown in Table 5.

[0051] Table 5 Effect of poloxamer concentration on celecoxib microspheres

[0052]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| floating rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com