Method for improving weld penetration of optical fiber laser welding

A fiber laser and weld penetration technology, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve problems such as laser welding weld penetration, and achieve the effect of improving weld penetration and welding efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

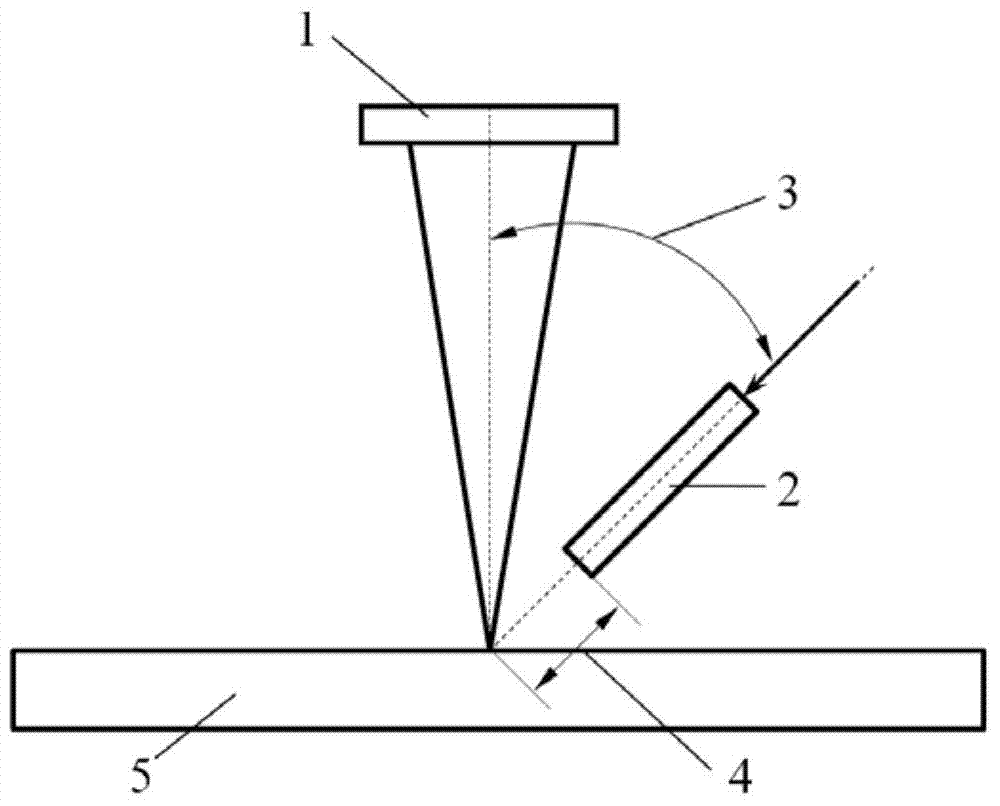

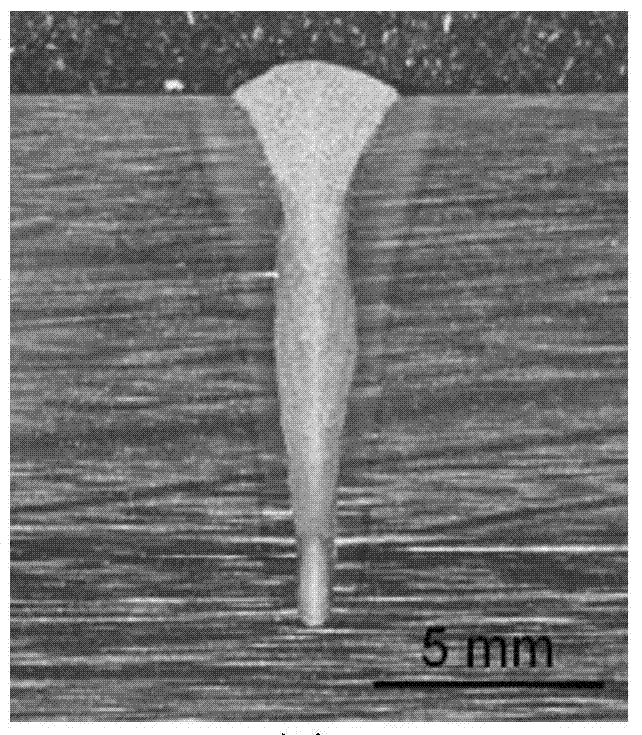

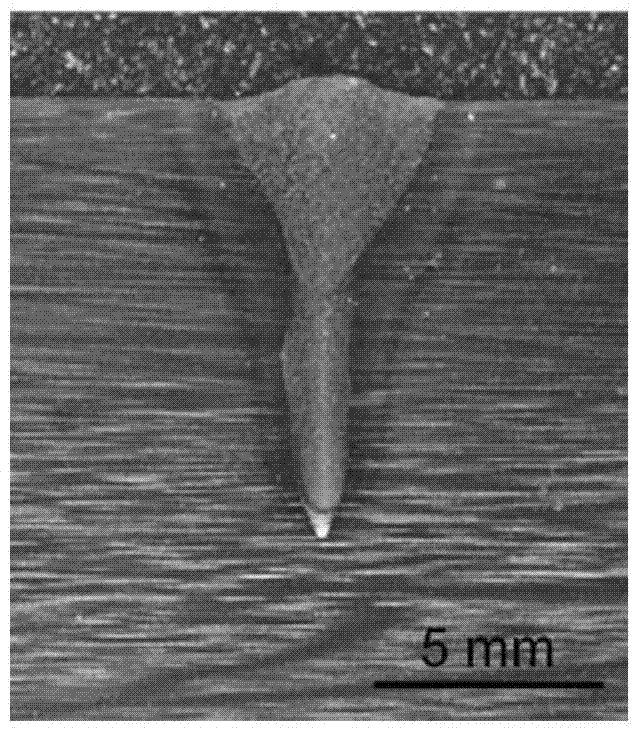

[0025] For the 20mm thick 780MPa grade high-strength steel, that is, the workpiece 5, the fiber laser welding method is adopted, wherein the laser power of the laser 1 is 7kW, the flow rate of the laser shielding gas 2 is 45L / min, and the welding speed is 1.0m / min; the shielding gas used The angle 3 between the nozzle and the laser beam is 45°, and the distance 4 between the nozzle and the workpiece is 12 mm. The original method is to use He as the shielding gas, and the shape of the laser pinhole is as follows Figure 5 As shown, the penetration depth of the weld is 9.5mm, such as image 3 shown. Now use He-20%O 2 As a shielding gas, the shape of the laser hole is as follows Figure 4 As shown, compared with He protection, the shape of the laser hole is significantly expanded, and the depth of the hole is greatly increased, so that the weld penetration depth reaches 11.5mm, as shown in figure 2 shown. It is proved that when a small amount of active gas is added to the i...

Embodiment 2

[0027] For the 20mm thick 780MPa grade high-strength steel, that is, the workpiece 5, the fiber laser welding method is adopted, wherein the laser power of the laser 1 is 7kW, the flow rate of the laser shielding gas 2 is 20L / min, and the welding speed is 1.0m / min; the shielding gas used The angle 3 between the nozzle and the laser beam is 45°, and the distance 4 between the nozzle and the workpiece is 15 mm. The original method uses Ar as the shielding gas, and the weld penetration depth is 8.7mm, such as Figure 7 shown. Ar-50%CO is now used 2 When used as a shielding gas, the weld penetration reaches 10.4mm, such as Image 6 shown. Using Ar-CO 2 Mixed gas as a shielding gas can effectively improve the weld penetration.

Embodiment 3

[0029] For the 25mm thick 490MPa grade low carbon steel, that is, the workpiece 5, the fiber laser welding method is adopted, wherein the laser power of the laser 1 is 10kW, the flow rate of the laser shielding gas 2 is 30L / min, and the welding speed is 1.0m / min; The angle 3 between the gas nozzle and the laser beam is 40°, and the distance 4 between the nozzle and the workpiece is 10 mm. When the original method uses Ar as the shielding gas, the weld penetration depth is 11.9mm. And now using Ar-20%O 2 When used as a shielding gas, the weld penetration reached 14.2mm, and the penetration increased by about 19%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com