Injection molding process

An injection molding process and particle technology, applied in the direction of coating, etc., can solve the problems of difficult to meet the production requirements, complicated process steps, and low quality of finished products, and achieve the effects of shortening the molding cycle, reducing costs, and saving raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

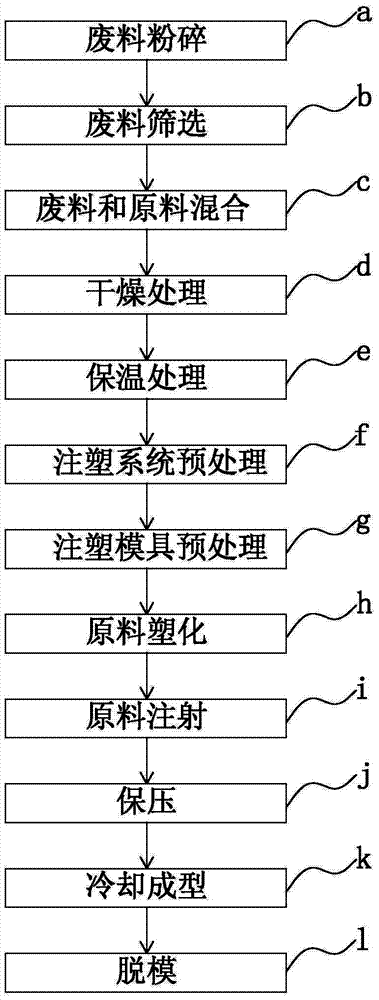

[0033] refer to figure 1 , a kind of injection molding technique of the present invention, comprises the following steps successively:

[0034] a) Crushing the injection molding waste;

[0035] b) Screen the crushed waste particles through a sieve with a sieve hole diameter of 0.41-0.56 cm, and screen out the waste particles that meet the requirements;

[0036] c) Proportion the waste granules that meet the requirements in step b) and the ABS raw material granules by weight to form a mixed raw material. The ratio of waste granules: ABS raw material granules is 23:77, and the mixed raw materials enter the oven through the automatic feeding mechanism;

[0037] d) Drying treatment of raw materials: use an oven to dry the mixed raw materials at a temperature of 123° C. for 0.5 hours;

[0038] e) Heat preservation treatment of raw materials: put the dried mixed raw materials into an environment of 96°C for heat preservation treatment for 1.5 hours;

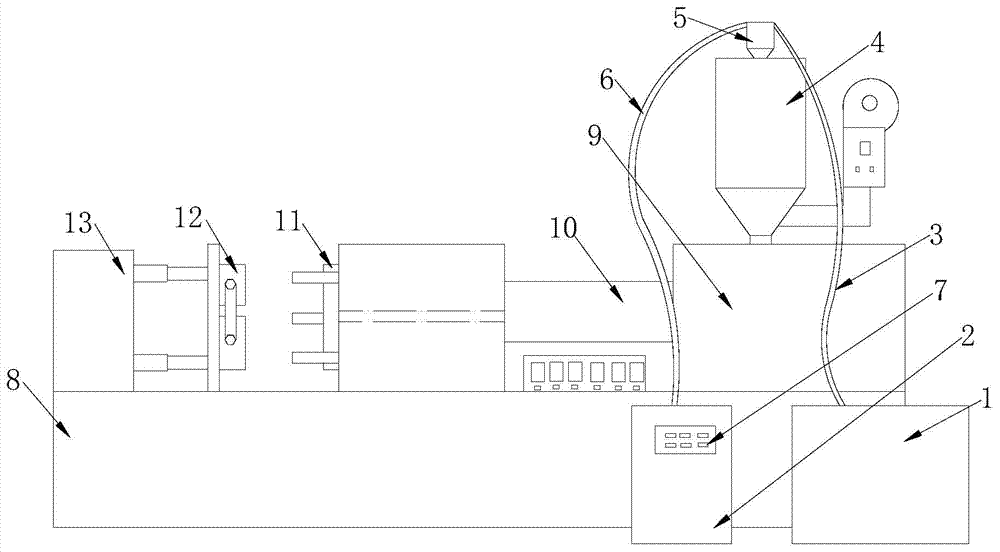

[0039] f) Pretreatment of in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com