Polyester resin used for TGIC-cured high-adhesive-force high-leveling-property powder coating and preparation method of the polyester resin

A powder coating, polyester resin technology, applied in powder coatings, polyester coatings, coatings and other directions, can solve the problems of acrylic coatings peeling off, inability to meet the coating and coating, and the adhesion is difficult to meet the requirements of use, etc. To achieve the effect of excellent leveling performance and excellent adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

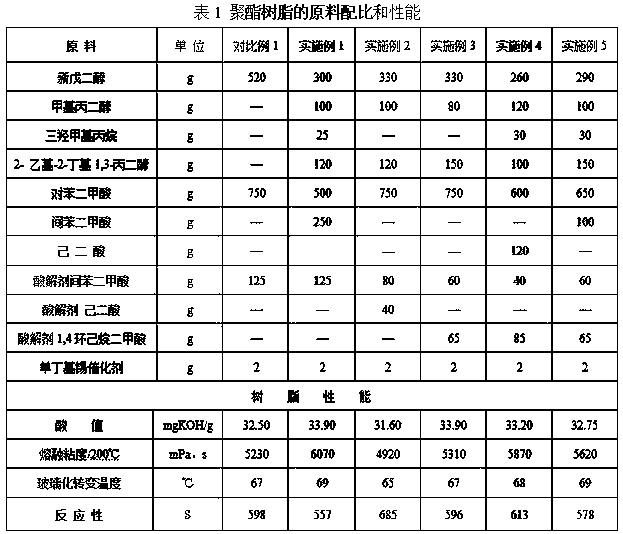

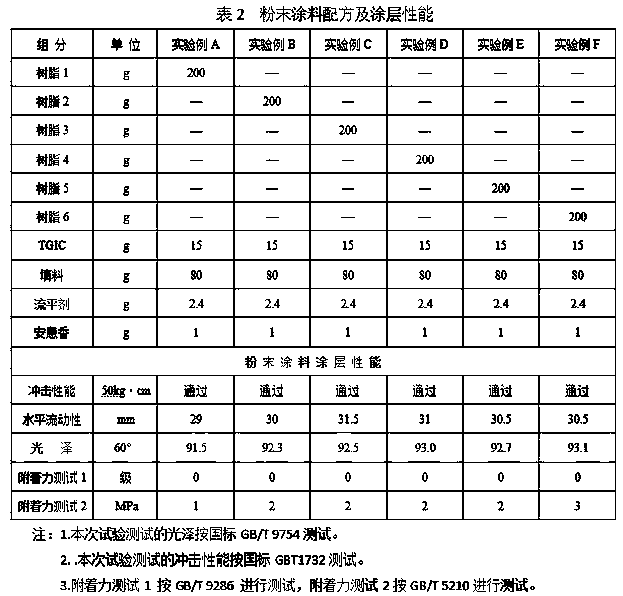

[0013] Table 1 is the embodiment and comparative example of polyester resins for high adhesion and high leveling powder coatings. The specific implementation method is as follows: under nitrogen protection, add Neopentyl glycol, methylpropanediol, trimethylolpropane, 2-ethyl-2-butyl 1,3-propanediol in the proportions listed in Table 1 were heated and stirred to dissolve, then added terephthalic acid, adipic di Acid, isophthalic acid and monobutyltin catalyst, gradually warming up to about 180°C to start esterification and water distilled out, then gradually warming up to 240°C, esterification and polycondensation reaction for 13 hours, the esterification rate reached more than 95%, the acid value When the acid value reaches 10-15mgKOH / g, add acidolysis agent isophthalic acid, adipic acid or 1,4-cyclohexanedicarboxylic acid, and conduct vacuum condensation at 240°C for 5 hours when the acid value reaches 43-47mgKOH / g 2h to obtain polyester resin acid value 30 ~ 37mgKOH / g, visco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com