Low-temperature-curing and superhigh-temperature-resistant coating, and preparation method and application of coating

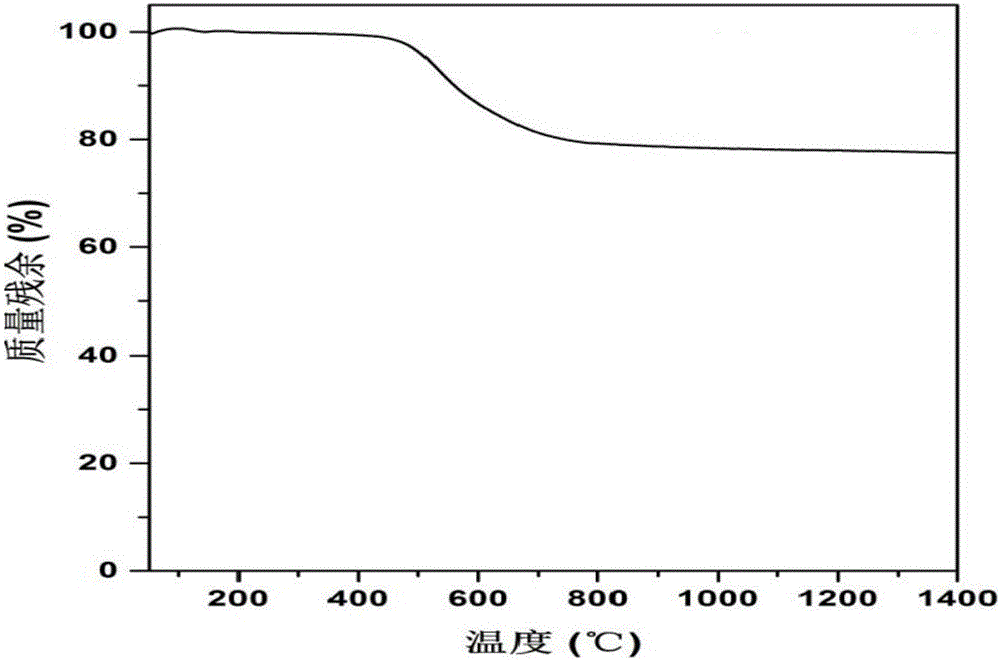

An ultra-high temperature and low temperature technology, applied in the field of materials, can solve the problems of poor coating adhesion, high temperature oxidation resistance, high thermal shrinkage rate, etc., and achieve excellent adhesion, ultra-low thermal expansion rate and low thermal expansion rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A low-temperature curing ultra-high temperature resistant coating, its raw materials are composed of the following components by mass percentage: 20% hyperbranched polysilaborazane with a number average molecular weight of 2670g / mol and a polydispersity coefficient of 1.53, 30% with a particle size of 100nm composite filler, 4% triethylamine, 40% petroleum ether, 1% polydimethylsiloxane, 2% hexenyl bisstearamide, 3% polydimethylsiloxane , the sum of the mass percentages of each raw material component is 100%;

[0037] Wherein, the composite filler is composed of the following components by mass percentage: 50% graphite powder, 5% zirconium silicate, 15% boron carbide, 10% boron nitride, 15% zirconium boride, 15% Titanium boride, the sum of the mass percentages of each raw material component is 100%;

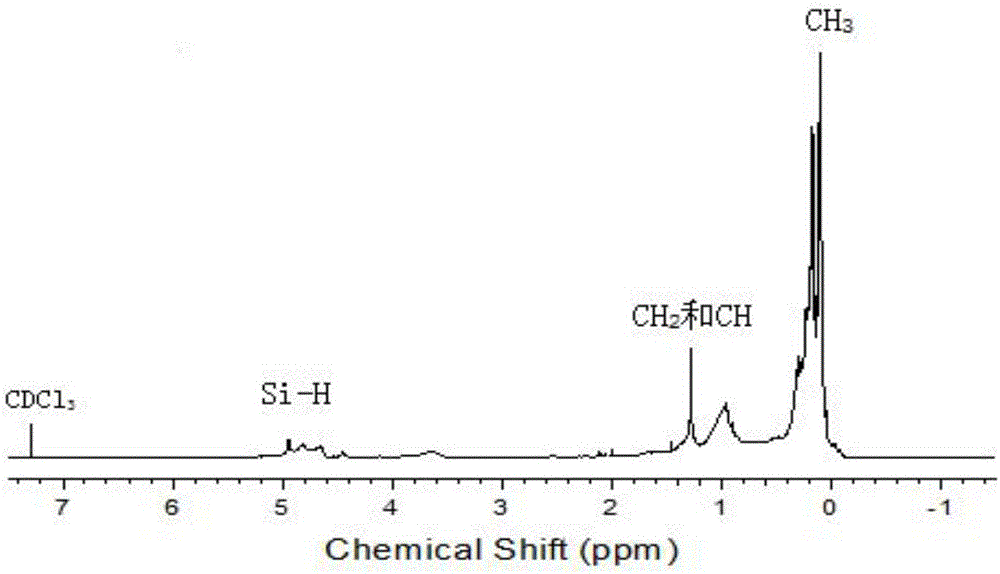

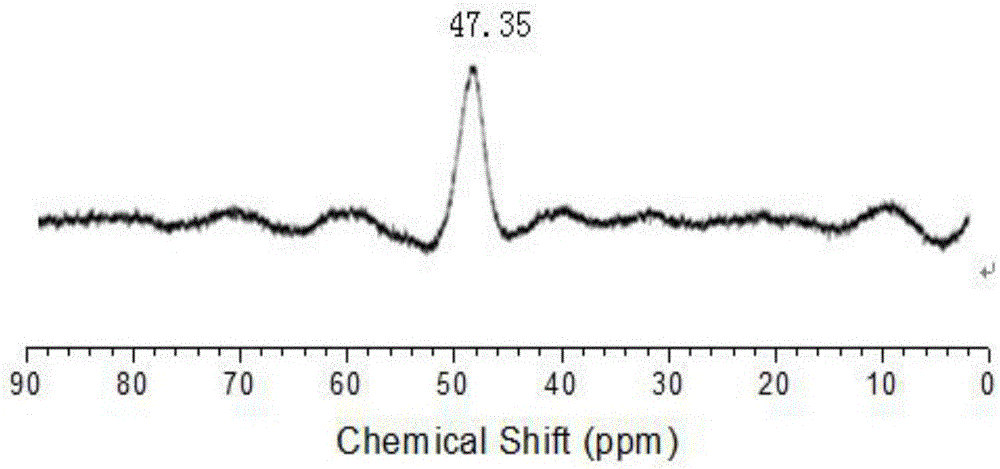

[0038] Wherein, the hyperbranched polysilaborazane structure used is:

[0039]

[0040] Concrete preparation steps are as follows:

[0041] Step 1, the synthesis of ...

Embodiment 2

[0050] A low-temperature curing ultra-high temperature resistant coating, its raw materials are composed of the following components by mass percentage: 30% hyperbranched polysilaborazane with a number average molecular weight of 2670g / mol and a polydispersity coefficient of 1.53, 30% with a particle size of 10nm composite filler, 3% dimethyl sulfide, 30% p-xylene, 3% dimethylpolysiloxane, 2% monoglyceride stearate, 2% polymethylphenyl Siloxane, the sum of the mass percentages of each raw material component is 100%;

[0051] Wherein, the composite filler is composed of the following components by mass percentage: 40% graphite powder, 10% zirconium silicate, 10% boron carbide, 15% boron nitride, 15% zirconium boride, 10% Titanium boride, the sum of the mass percentages of each raw material component is 100%;

[0052] Wherein, the hyperbranched polysilaborazane structure used is:

[0053]

[0054] Concrete preparation steps are as follows:

[0055] Step 1, step 2 are the s...

Embodiment 3

[0063] A low-temperature curing ultra-high temperature resistant coating, its raw materials are composed of the following components by mass percentage: 20% hyperbranched polysilaborazane with a number average molecular weight of 2670g / mol and a polydispersity coefficient of 1.53, 10% with a particle size of 1000nm composite filler, 6% palladium / carbon, 60% ethyl acetate, 2% simethicone, 1% polyethylene glycol 400, 1% melamine formaldehyde resin, the mass of each raw material component The sum of the percentages is 100%;

[0064] Wherein, the composite filler is composed of the following components by mass percentage: 60% graphite powder, 10% zirconium silicate, 5% boron carbide, 5% boron nitride, 5% zirconium boride, 15% Titanium boride, the sum of the mass percentages of each raw material component is 100%;

[0065] Wherein, the hyperbranched polysilaborazane structure used is:

[0066]

[0067] Concrete preparation steps are as follows:

[0068] Step 1, step 2 are the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com