Composition used for electrolytic deposition copper and acid copper electroplating solution

A technology of electrolytic deposition and composition, applied in the field of electroplating deposition, can solve problems such as copper layer thickness, voids, blind hole filling depressions, etc., and achieve good leveling performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

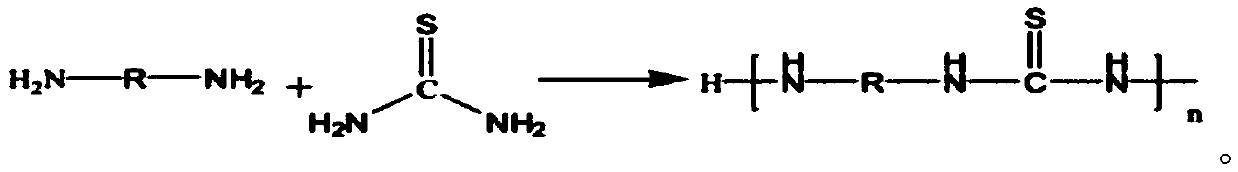

Method used

Image

Examples

Embodiment 1

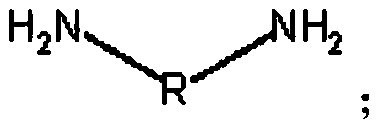

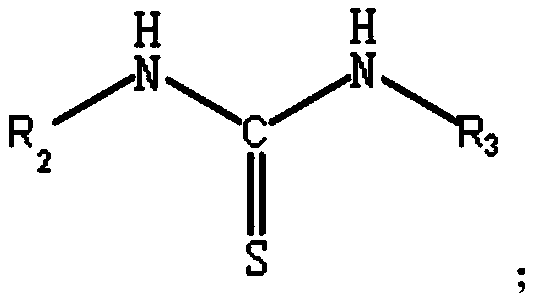

[0042] Weigh 10.4g of diethylenetriamine and 7.2g of thiourea into a three-necked flask, heat the water bath to 100°C, react for 3 hours, and cool to room temperature to obtain a yellow liquid, add 50ml of acetonitrile as a solvent, and dropwise add 2.5g of allyl The base chloride was heated to reflux for 12 hours, and the solvent and excess allyl chloride were removed under reduced pressure to obtain a modified composition.

Embodiment 2

[0044] Weigh 8g of hexamethylene diamine and 7.2g of thiourea into a three-necked flask, heat the water bath to 100°C, react for 3 hours, and cool to room temperature to obtain a yellow liquid. Add 50ml of acetonitrile as a solvent, and dropwise add 2.1g of benzyl chloride. Base chloride) was heated to reflux for 12 hours, the solvent was removed under reduced pressure and washed, thereby obtaining a modified composition.

Embodiment 3

[0046] The electroplating solution was prepared according to the proportioning ingredients in Table 1, wherein the modified composition was obtained according to Example 1.

[0047] Table 1 Example 3 Electroplating solution composition ratio table

[0048]

[0049] In order to verify the effectiveness of the modified composition provided by this solution in the acid copper electroplating solution, a comparative example 1-2 and this example 3 were prepared below for comparative analysis.

[0050] Wherein, the electroplating solution of Comparative Example 1 was prepared according to the composition ratio in Table 2, and the electroplating solution of Comparative Example 2 was prepared according to the composition ratio in Table 3.

[0051] Table 2 Comparative example 1 Electroplating solution composition ratio table

[0052] Bath composition CuSO4·5H2O H2SO4 CL- SPS PEG 6000 concentration 200g / L 50g / L 50mg / L 1mg / L 1g / L

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com