Flame retardant-type waterproof sealing hot-melt pressure-sensitive adhesive and preparation method thereof

A hot-melt pressure-sensitive adhesive and waterproof sealing technology, applied in the direction of adhesives, adhesive types, adhesive additives, etc., can solve problems such as equipment damage, poor waterproofness, fire, etc., and achieve high bonding strength and excellent insulation effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

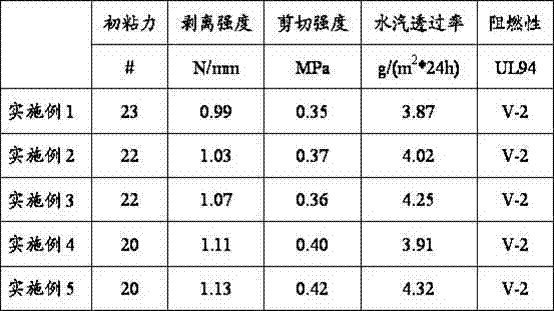

Examples

Embodiment 1

[0034] The temperature of the kneader is raised to 90°C, 40 parts of butyl 268 rubber, 20 parts of brominated butyl rubber, 20 parts of polyisobutylene B50, 100 parts of polyisobutylene B12, 30 parts of SBS, 100 parts of octyl phenolic resin, 10 parts of zinc oxide 10 parts, antioxidant 1010 2 parts were added to the kneader, after fully kneading for 1 hour, 10 parts of mineral oil, 80 parts of decabromodiphenyl ether, 40 parts of antimony trioxide, 150 parts of aluminum hydroxide, and 30 parts of carbon black were sequentially added After the addition is completed, keep the temperature at 130°C for 2 hours and then discharge the material. After cooling to room temperature, a flame-retardant hot-melt pressure-sensitive adhesive is obtained.

Embodiment 2

[0036] The temperature of the kneader is raised to 90°C, 20 parts of butyl 268 rubber, 60 parts of brominated butyl rubber, 30 parts of polyisobutylene B50, 120 parts of polyisobutylene B12, 40 parts of SBS, 70 parts of octyl phenolic resin, 15 parts of zinc oxide 3 parts, antioxidant 1010 3 parts were added to the kneader, after fully kneading for 2 hours, 20 parts of mineral oil, 110 parts of decabromodiphenyl ether, 50 parts of antimony trioxide, 100 parts of aluminum hydroxide, and 30 parts of carbon black were sequentially added After the addition is completed, keep the temperature at 140°C for 3 hours and then discharge the material. After cooling to room temperature, a flame-retardant hot-melt pressure-sensitive adhesive is obtained.

Embodiment 3

[0038] The temperature of the kneader is raised to 110°C, 50 parts of butyl 268 rubber, 40 parts of brominated butyl rubber, 50 parts of polyisobutylene B50, 150 parts of polyisobutylene B12, 50 parts of SBS, 80 parts of octyl phenolic resin, 20 parts of zinc oxide 4 parts, antioxidant 1010 were added to the kneader, kneaded fully for 2 hours, then added 15 parts of mineral oil, 150 parts of decabromodiphenyl ether, 60 parts of antimony trioxide, 120 parts of aluminum hydroxide, 30 parts of carbon black After the addition is completed, keep the temperature at 140°C for 3 hours and then discharge the material. After cooling to room temperature, a flame-retardant hot-melt pressure-sensitive adhesive is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com