Road sound insulation barrier

A technology for sound insulation barriers and roads, applied in buildings, noise absorption devices, etc., can solve the problems of not meeting the service cycle, high maintenance costs, long line costs, etc., to meet the requirements of use, low maintenance costs, Long service life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

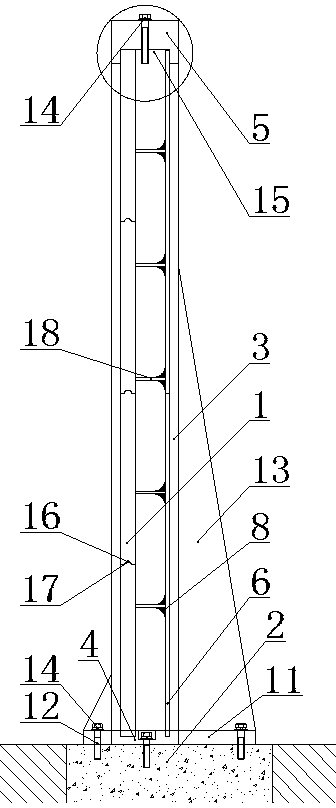

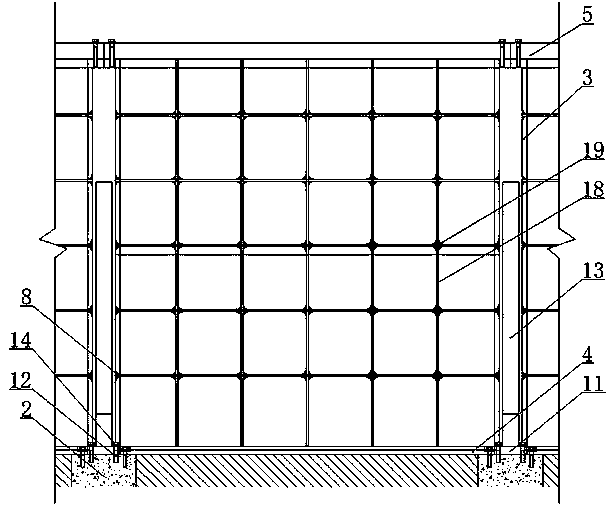

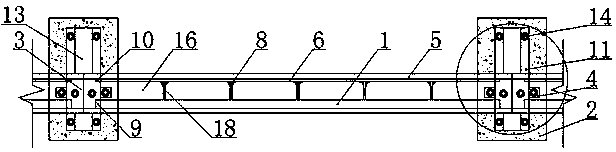

[0014] Such as figure 1 , 2 , In the embodiment shown in 3, 4, and 5, a road sound insulation barrier is composed of a main structural member, a sound-absorbing panel (1), and a sound-insulation strengthening structure. The main structural components are composed of reinforced concrete base (2), structural columns (3), load-bearing beams (4) and concave tension beams (5). The structure is composed of sound insulation boards (6) and square diaphragm-shaped stiffeners (7), which are arranged in the direction facing away from the noise source, and flexible anti-crack mortar (8) is used as adhesive and plugging agent. The structural column (2) is prefabricated by reinforced concrete, and two grooves are arranged on the side of the structural column (3), the wide groove (9) is at the front, the narrow groove (10) is at the rear, and the structural column (2) The lower part is the base floor (11), and the base floor (11) has four installation holes (12), and the front and back of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com