Reinforced structure of thin-wall hydraulic structure and reinforcing method

A technology for strengthening structures and structures, applied in water conservancy projects, buildings, artificial waterways, etc., can solve the problem of poor bonding performance between the glass fiber cloth and the original structural layer of the aqueduct, no obvious improvement in durability and aging resistance, and carbon fiber reinforcement costs. High problems, to achieve the effect of easy guarantee of construction quality, good aging resistance and good reinforcement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

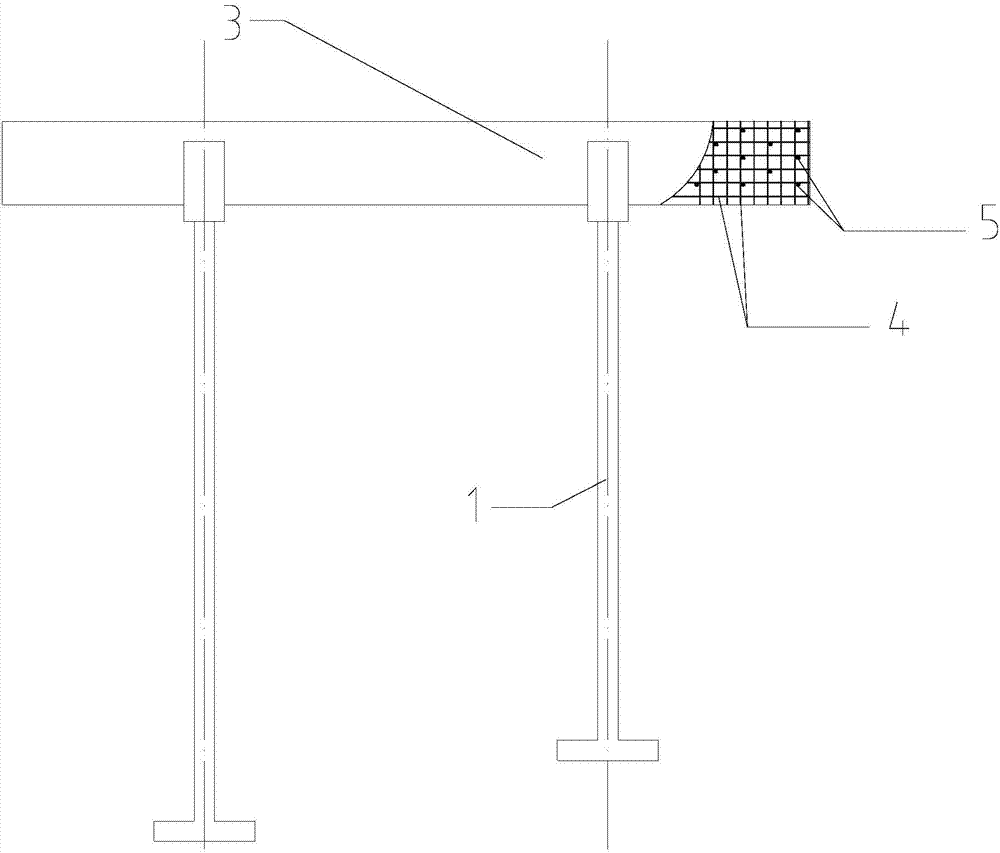

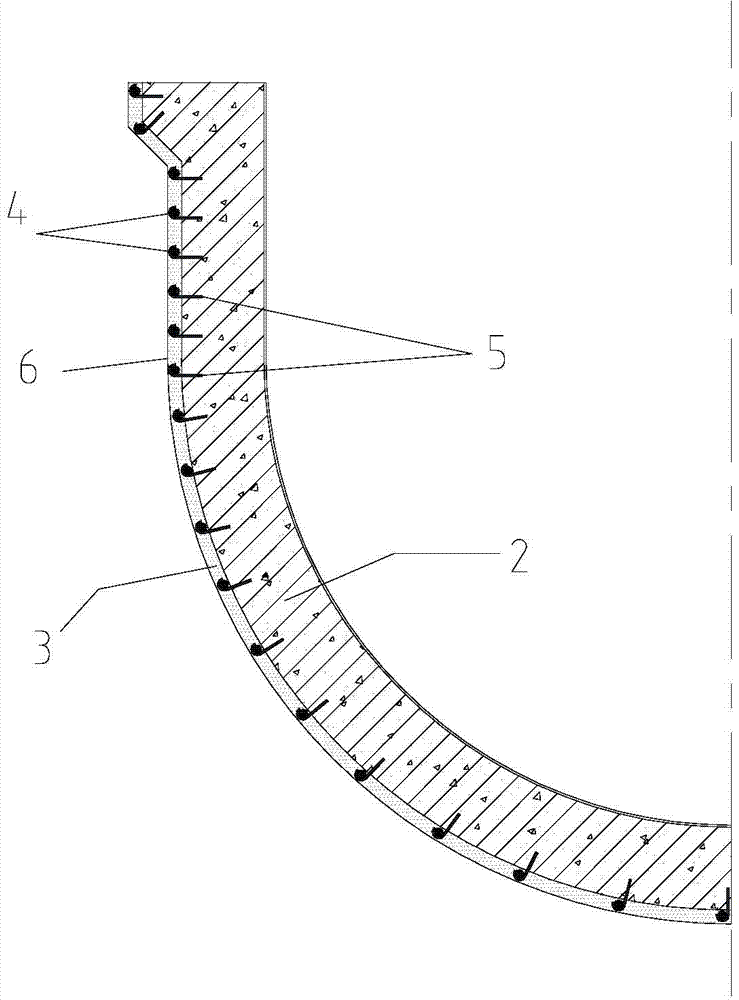

[0031] The body of an aqueduct is a thin-walled structure of U-shaped steel wire mesh without tie rods, and the longitudinal direction is a double-cantilever assembled symmetrical structure with a total length of 108m. The supporting structure mainly adopts supporting bent frames 1, and its maximum supporting height is 13.5m. The aqueduct has been put into use for more than 40 years since its completion. Although it has undergone two anti-seepage reinforcements during the period, due to long-term use, coupled with reasons such as design, management, and maintenance, the current situation of the aqueduct is not optimistic. The main manifestations are: The following aspects:

[0032] (1) The thin layer of modified mortar sprayed on the outer wall of the aqueduct falls off;

[0033] (2) The carbonization of the mortar leads to corrosion of the steel bars, and the volume of the steel bars expands after corrosion, resulting in cracking of the mortar;

[0034] (3) The waterstop at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com