Earth borrowing method in process of highway construction

A highway construction and highway technology, applied in construction, infrastructure engineering, on-site foundation soil survey and other directions, can solve the problems of waste of land and damage to the environment, large amount of soil used for construction, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

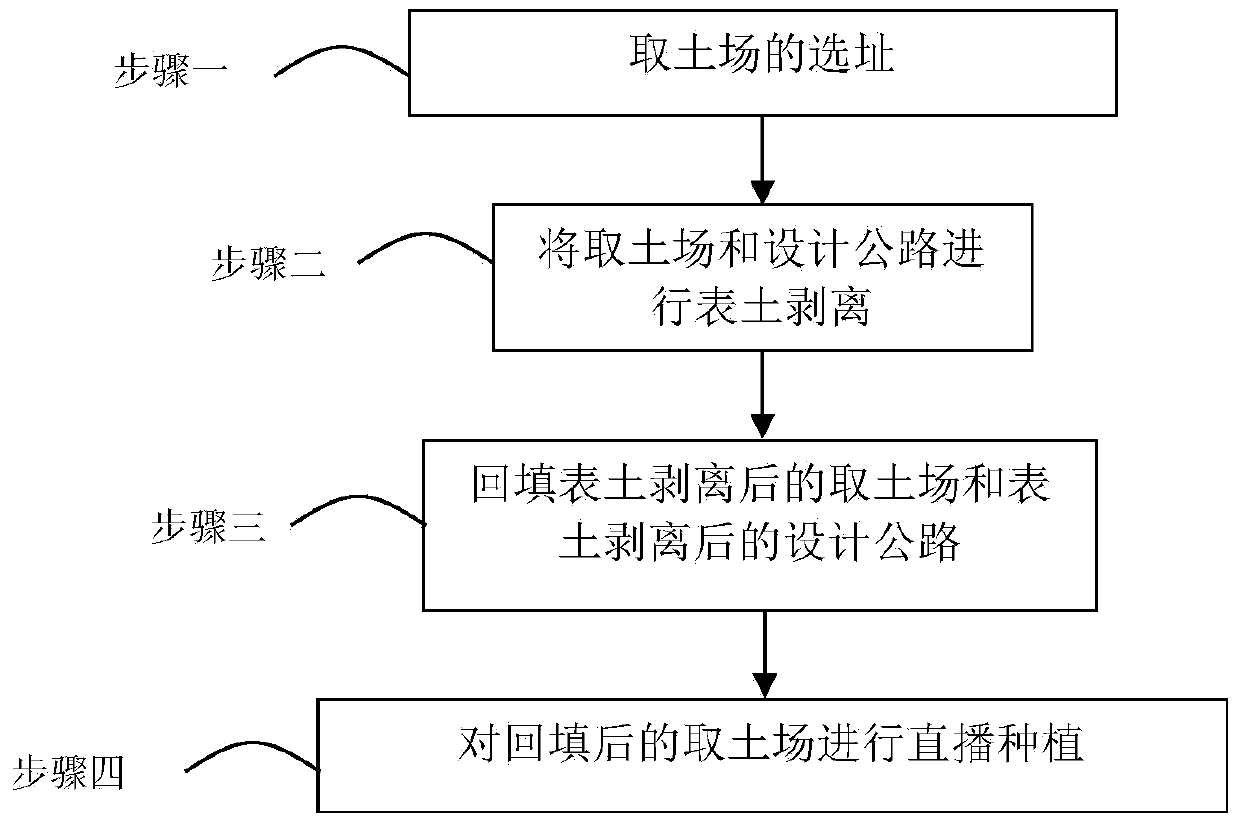

[0015] Specific embodiment 1: The method for borrowing soil in the process of highway construction in this embodiment is specifically prepared according to the following steps:

[0016] Step 1. Site selection of borrow pit;

[0017] Step 2: Strip the topsoil of the borrow site and the designed highway;

[0018] Step 3. Backfill the borrow pit after the topsoil stripped and the designed road after stripped topsoil;

[0019] Step 4. Live planting on the borrow yard after backfilling; that is, a method of borrowing in the road construction process is completed. figure 1 Shown.

[0020] Effects of this implementation:

[0021] This embodiment proposes a soil extraction method in the process of road construction. By using this method, soil extraction can not only protect the environment, improve the soil, but even generate new arable land and increase the yield of crops on rural land. On the premise of respecting regulations and laws and ensuring the maintenance of social stability, this im...

specific Embodiment approach 2

[0025] Specific embodiment two: this embodiment is different from specific embodiment one in that the process of selecting the site of the borrow pit in step one is:

[0026] (1) Choosing the borrow yard Choose the borrow yard according to the principle of the proximity of the borrow yard and the designed road; the borrow yard shall be based on the shape of the borrow pit, the area of the borrow pit, the volume of the borrow pit, and the best depth of the borrow pit. , The slope of the borrow pit, the green area required to establish the borrow pit after borrowing, the drainage facilities of the borrow pit, the high hills of the borrow pit, the contour line of the sand dune of the borrow pit, and the volume of the borrow pit-the volume of the borrow pit Select the effect drawing drawn by volume and the road design plan;

[0027] (2) The selected borrow yard adopts the cost approximation method to calculate the cost of each borrow yard, and adopts the income reduction method and t...

specific Embodiment approach 3

[0029] Specific embodiment three: this embodiment is different from specific embodiment one or two in that the process of stripping the topsoil from the borrow pit and the designed highway in step two is:

[0030] (1) Strip the topsoil of the land in the borrow pit area, and the depth of the borrow should be smoothly transitioned to the surrounding cultivated land; the thickness of the stripped soil layer is not less than 30cm, and the thick topsoil layer needs to be cleared to the bottom of the cultivated soil; bulldozers Bulldoze the pile, and then use the loader and dump truck to pile the surface soil of the borrow yard on the yard around the design road borrow pit to avoid mixing of the surface soil and the deep soil;

[0031] (2) To strip the topsoil of the designed highway, first select a soil storage yard on the designed highway, use a bulldozer to bulldoze the pile, and then use a loader and a dump truck to stack the designed highway topsoil on the yard around the borrow pit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com