Construction method for post-cast belt of cast-in-place reinforced concrete structure

A technology of reinforced concrete and post-pouring strips, which is applied in the direction of building structure, construction, and building material processing. It can solve the problems of uneven settlement, concrete deformation, and large plane size of the main building and annex buildings, and shorten the construction period. Reduce the amount of input and improve the overall effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

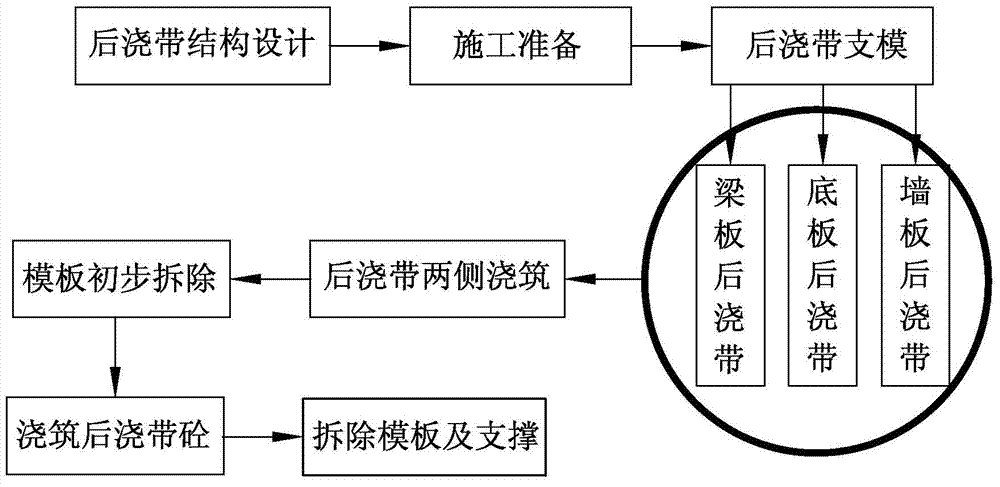

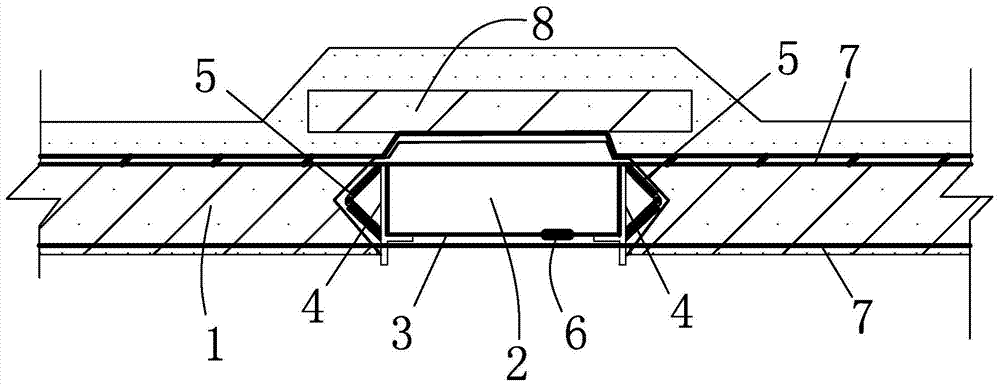

[0031] The post-cast belt construction method of the cast-in-situ reinforced concrete structure of the present invention utilizes the post-cast belt for segmental construction, establishes the post-cast belt formwork, protects the post-cast belt through the support system, and provides retention time for digestion, settlement, shrinkage, and deformation during construction. Improved project quality.

[0032] The following materials are required for this construction method:

[0033] 1. 15 thick plywood for construction, φ48 steel pipe, steel pipe jacking, 50×100 wooden frame, dense mesh steel wire mesh, iron wire, cement, etc.

[0034] 2. Construction tools and equipment:

[0035] 2.1. Template prefabrication and installation tools: electric saw, electric planer, hand saw, spirit level, spirit level, steel tape measure;

[0036] 2.2. Reinforcement processing and installation equipment: electric welding machine, bending machine, cutting machine;

[0037] 2.3. Concrete pourin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com