Two-level turbocharging system and engine with two-level turbocharging system

A turbocharger system and turbocharger technology, applied in combustion engines, machines/engines, internal combustion piston engines, etc., can solve the problem of supercharging pressure ratio, high-speed performance acceleration response effect is not very ideal, not very good Taking into account the high and low speed performance of the engine, the limited ratio and operating condition range, etc., to achieve the effect of good emission and plateau adaptability, large low-speed torque, and high power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

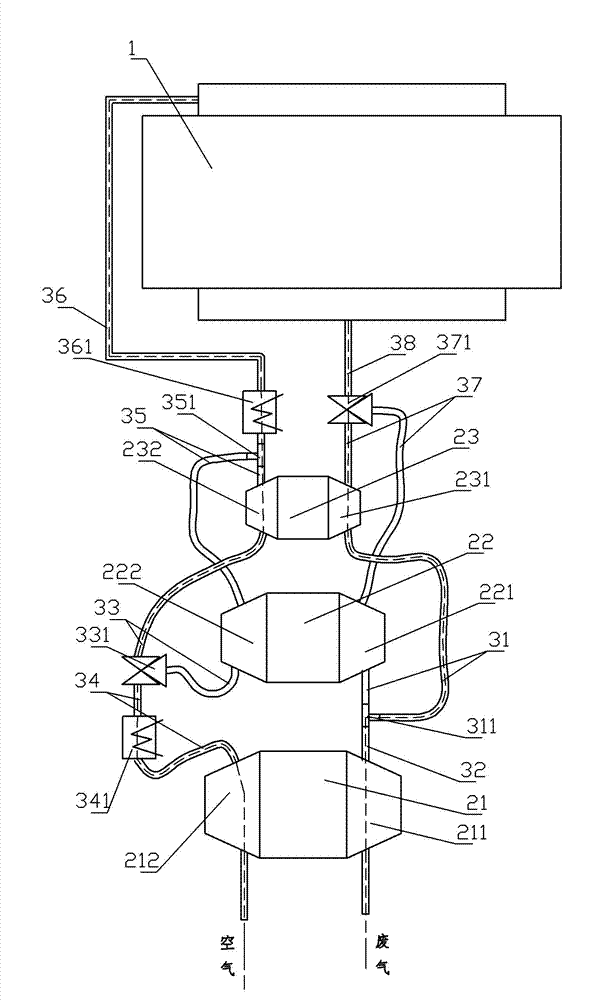

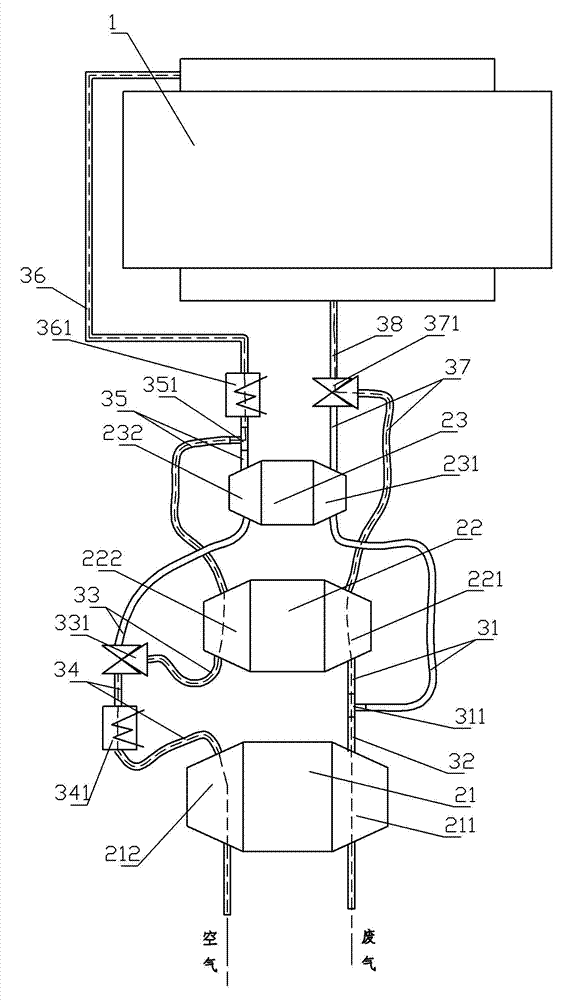

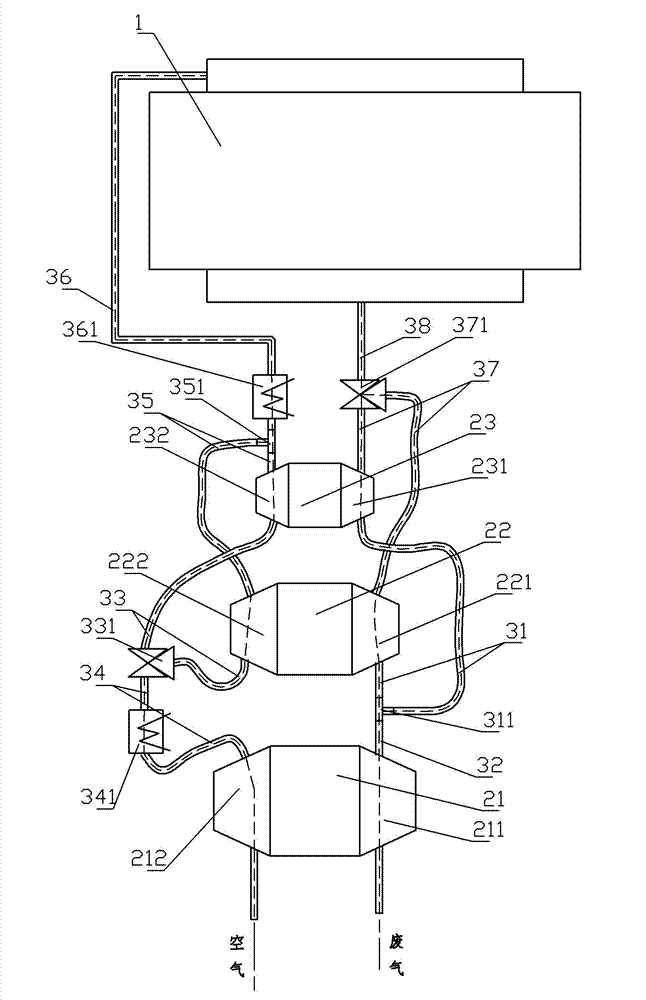

[0020] Such as figure 1 Shown: an engine with a two-stage turbocharging system, which includes engine 1 and a two-stage turbocharging system; engine 1 includes the engine mechanical assembly and an engine electronic control unit; the two-stage turbocharging system includes a large turbocharger Turbocharger 21, medium turbocharger 22, small turbocharger 23 three flow unequal turbochargers (the described large, medium and small are relative terms, not absolute values, for distinguishing the three The flow rates of two turbochargers are unequal; the unequal flow rate means that at the same rotational speed, the air intake volume of the turbocharger is not equal, which generally manifests as unequal diameters of the blades of the turbocharger on the macroscopic structure, that is, large The flow rate of the turbocharger is greater than the flow rate of the medium turbocharger (at the same speed, generally the rated flow rate), and the flow rate of the medium turbocharger is greate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com