A car carbon deposit cleaner

A cleaning and carbon deposition technology, applied in the direction of machine/engine, mechanical equipment, engine components, etc., can solve the problems of high cleaning cost, uneconomical, inconvenient use, etc., and achieve the effect of light weight, small volume and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

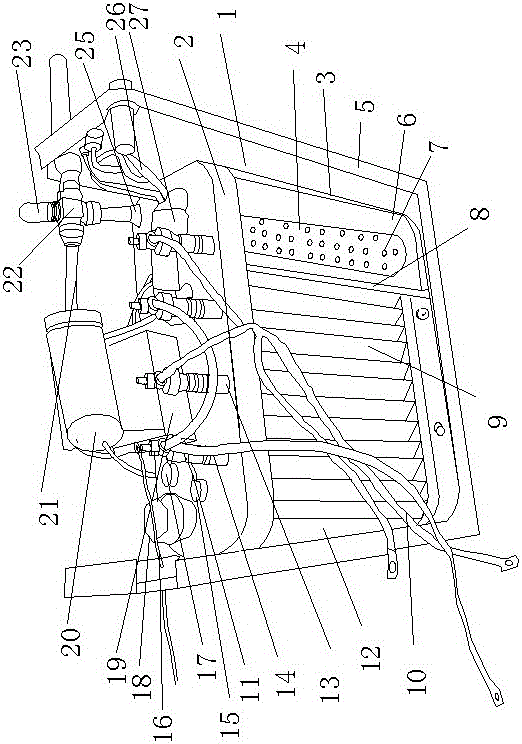

[0026] Example 1, such as figure 1As shown, a car carbon deposit cleaner includes a frame body 5, a gas generating device, and a pressurizing device. The gas generating device includes at least one carbon deposit cleaner body 1, and the carbon deposit cleaner body 1 includes a box body 3 and the box cover 2 fastened on the top of the box body 3; a partition 8 is erected in the box body 3, and the box body 3 is divided into an electrolytic chamber 12 and a filter chamber 6 which are independent of each other through the partition board 8, The electrolysis chamber 12 and the filter chamber 6 are connected through a connecting pipe 27; the lid 2 on the top of the electrolysis chamber 12 is provided with an electrolyte inlet, and the electrolyte inlet is provided with a sealing cover 18. The electrolyte is 10-30% sodium hydroxide aqueous solution.

[0027] Described electrolysis chamber 12 is provided with some electrolytic plates 9 arranged in parallel, and electrolytic plate 9 ...

Embodiment 2

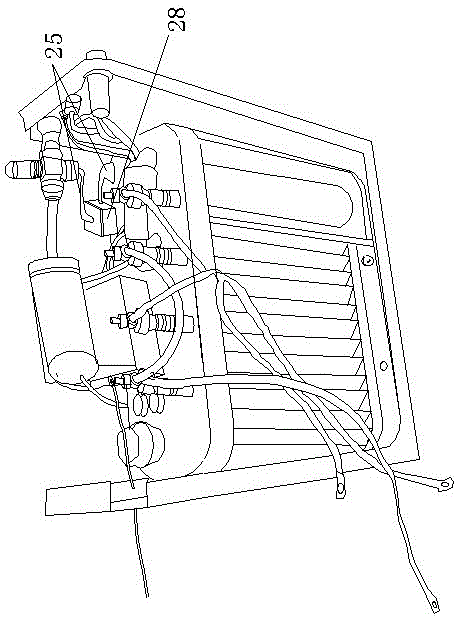

[0035] Example 2. The only difference between this embodiment and Embodiment 1 is that an anti-tempering water tank 28 is also provided on the filter outlet pipe 25 between the gas mixing chamber 22 and the outlet of the filter, and the anti-tempering water tank 28 is provided with Water that acts as a flame retardant.

Embodiment 3

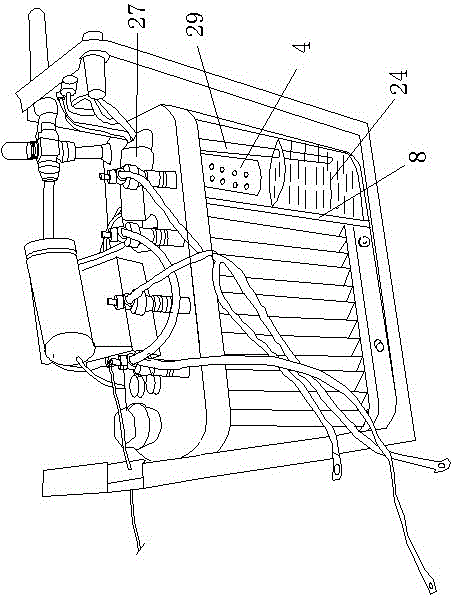

[0036] Example 3. The only difference between this embodiment and Embodiment 1 is that the connecting pipe 27 is located at one end of the filter chamber 6 and is connected with a conduit 29, the filter chamber 6 is equipped with filtered water 24 for filtering, and the bottom end of the conduit 29 extends into the Below the liquid level of the filtered water 24 ; the bottom of the filter 4 is located above the liquid level of the filtered water 24 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com