Method for screening equivalence ratios of combustion gas of foamed ceramic burner

A technology of foam ceramics and combustion gas, which is applied in the direction of combustion methods, burners, gas fuel burners, etc., and can solve problems such as complexity, inability to accurately simulate the combustion model, and inability to accurately obtain the combustion characteristics of the burner

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below in conjunction with the embodiments and accompanying drawings, but the embodiments of the present invention are not limited thereto.

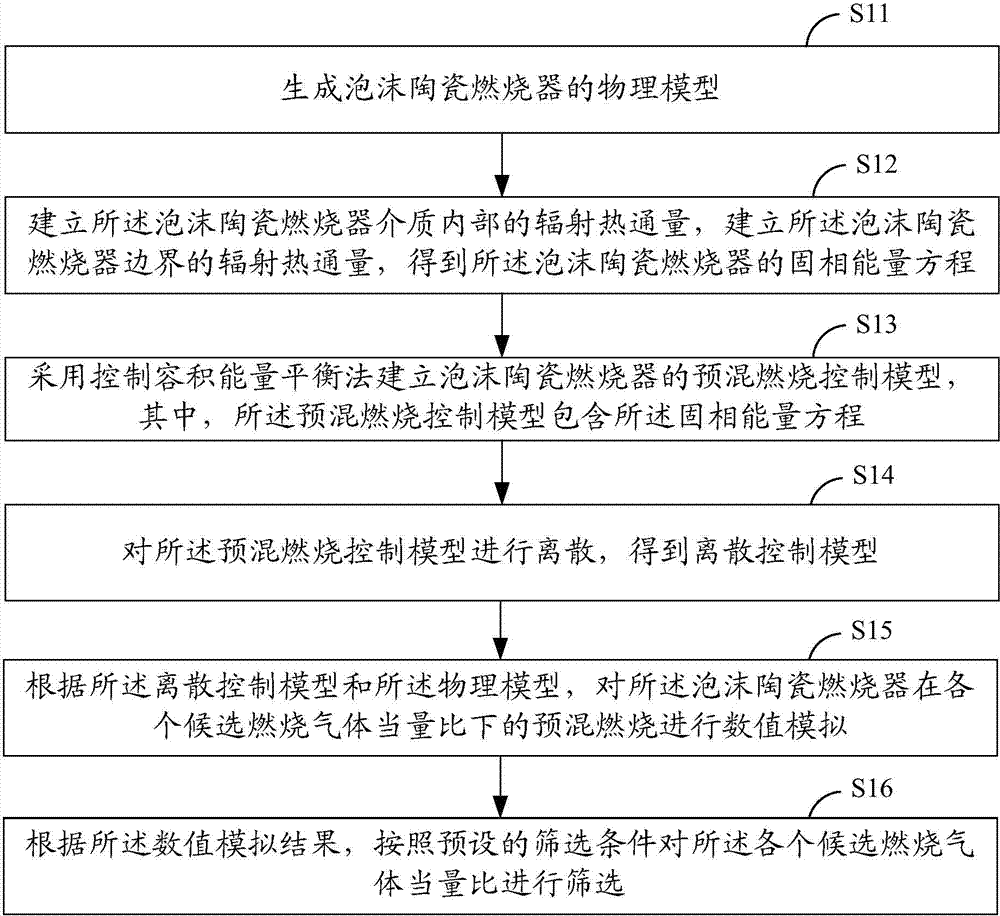

[0017] Such as figure 1 Shown is a schematic flow diagram of a screening method for the combustion gas equivalent ratio of a foam ceramic burner in an embodiment of the present invention, including the following steps:

[0018] S11, generating a physical model of the ceramic foam burner;

[0019] For the ceramic foam burner of the present embodiment, the whole device includes parts such as a burner, an igniter, a heat insulating layer, and a ventilation hole. The burner is mainly composed of a premixing chamber that can fully mix gas and air and a combustion tube with a porous ceramic foam core. The combustion pipe is vertically upward, and gas and air enter the chamber from the lower end of the premix chamber respectively. The premixing chamber is filled with large-diame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com