Integrated water-cooled radiator based on damping resistors

A technology of water-cooled radiators and damping resistors, which is applied in the direction of resistors, electric solid devices, resistor components, etc., can solve the problems of reducing the reliability of waterway connections, increasing the overall size of the structure, and large water consumption of radiators. Save internal space, reduce structural complexity, and improve cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in further detail below in conjunction with the accompanying drawings.

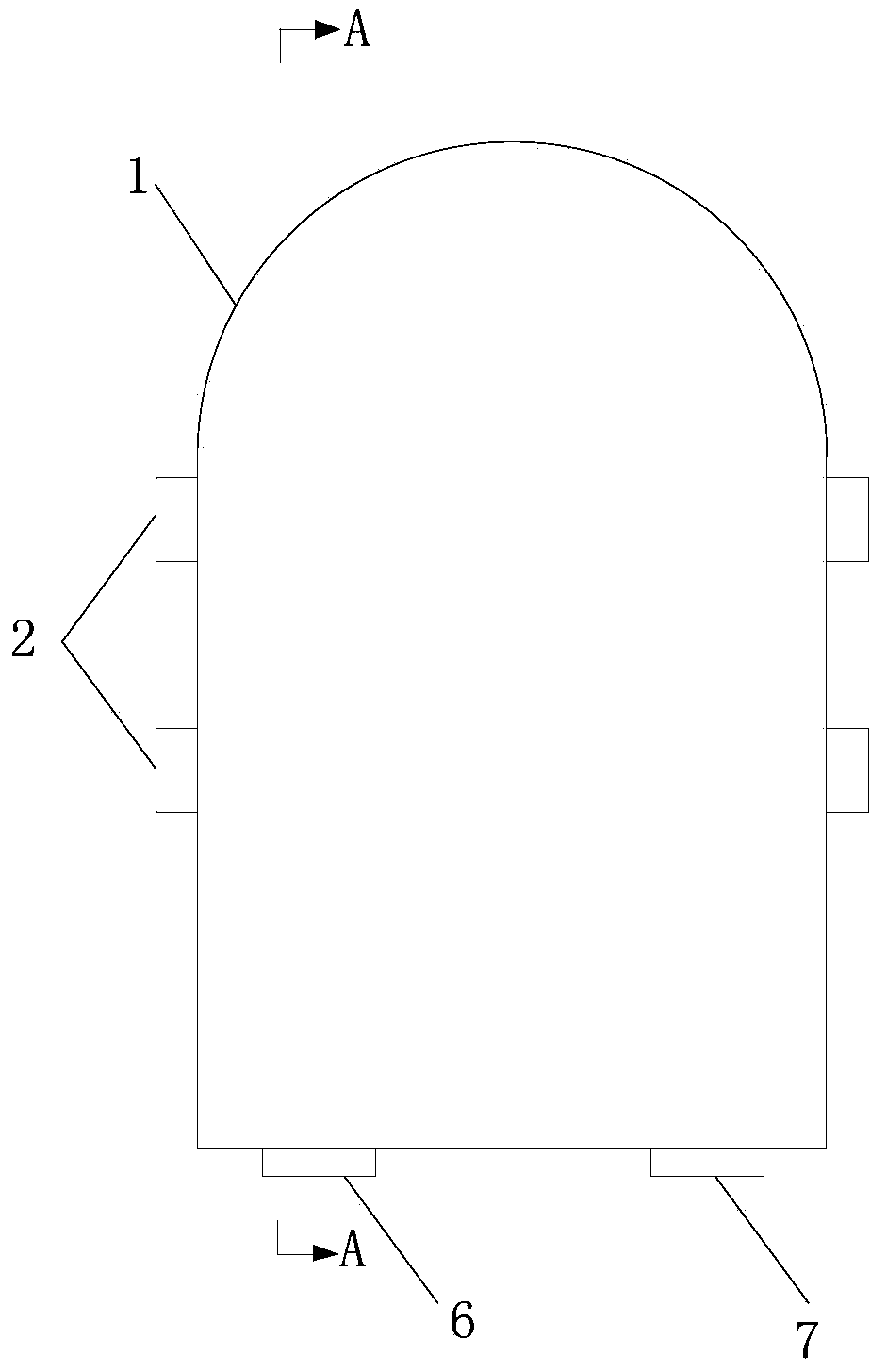

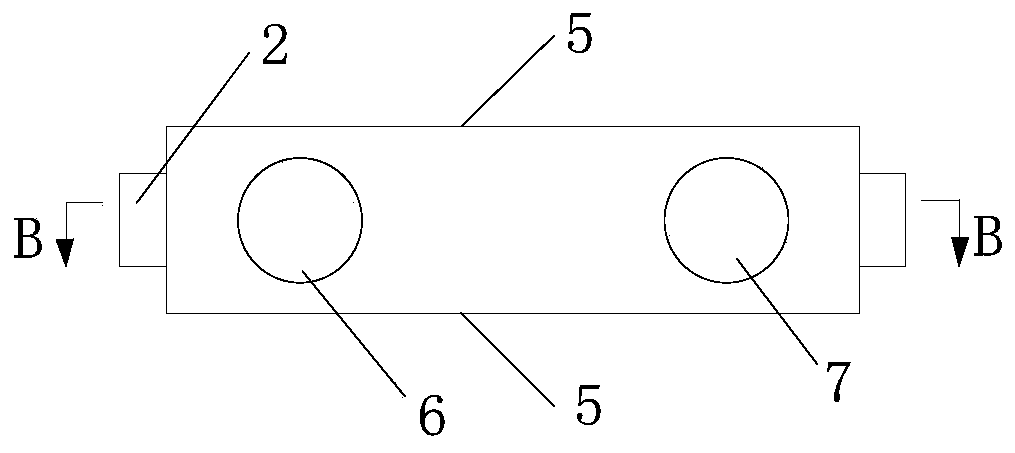

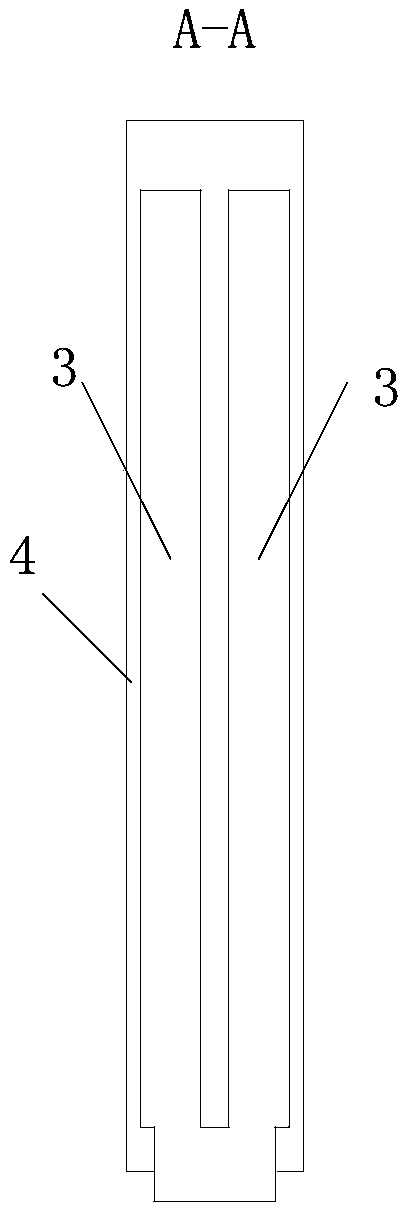

[0032] like Figure 1-Figure 4 , the present invention provides an integrated water-cooled radiator based on damping resistance. The radiator includes a radiator main body 1, a thyristor and a resistor. The radiator main body 1 includes an aluminum panel 4, a water channel 8 and a water channel wall 9. The radiator cavity 3, the water inlet 6 and the water outlet 7; the thyristor is attached to the surface of the aluminum panel 4, and the water inlet 6 and the water outlet 7 are arranged at the bottom of the radiator main body 1, so There are two radiator cavities 3 located inside the aluminum panel 4 ; the resistor is arranged on the water channel 8 .

[0033] The water channel 8 is a double-sided spiral structure and is made of aluminum material.

[0034] The waterway wall 9 is aluminum waterway wall with a thickness of 5-10mm.

[0035] The resistors inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com