Electrical penetrating connector for ceramic welding

A technology of electrical penetration and ceramic welding, applied in nuclear power generation, connection insulation, reduction of greenhouse gases, etc., to achieve good power transmission, simple structure, safe and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

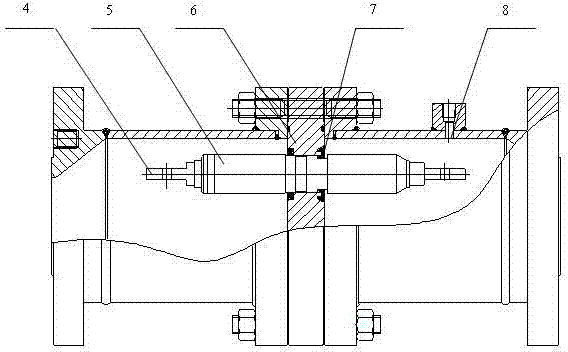

[0018] The ceramic welded electrical penetration joint includes a metal conductor 4, which also includes a ceramic insulator 5, and a metal connecting flange 6, which separates the medium from the atmosphere, and the metal conductor 4 passes through the metal connecting flange 6, and the metal conductor 4 and the Metal connecting flange 6 runs through metal conductor 4 and ceramic insulator 5 is covered, and metal connecting flange 6 is equipped with a pressure monitoring device 8 on the atmospheric side.

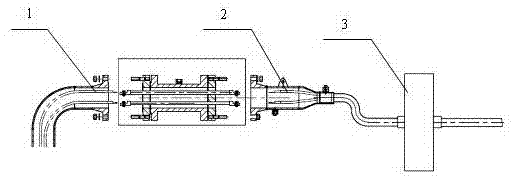

[0019] The ceramic welding electrical penetration joint is installed between the power cable 1 on the medium side and the power cable 2 on the atmosphere side to separate the atmosphere from the medium, and can effectively prevent the medium from leaking to the atmosphere. The power cable 2 on the atmosphere side is connected to the connection box 3. The metal connection flange 5 is used to isolate the medium from the atmosphere in the ceramic welding electrical penetration ...

Embodiment 2

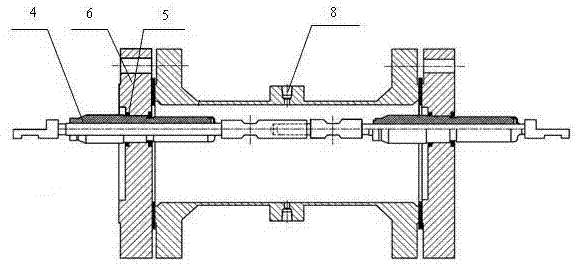

[0024] Double-layer ceramic welding electrical penetration joint, which includes ceramic welding electrical penetration joint I9, ceramic welding electrical penetration joint II10, one side of the ceramic welding electrical penetration joint I9 is the medium end, and the other side is the pressure monitoring cavity. One side of the through joint II10 is an intermediate pressure monitoring cavity, and the other side is the atmosphere. The pressure monitoring cavity is a sealed space, and a pressure detection device is installed in the pressure monitoring cavity. The pressure monitoring chamber is filled with inert gas.

[0025] Such as image 3 As shown, the double-layer ceramic welding electrical penetration joint is improved on the basis of the ceramic welding electrical penetration joint, and the double-layer ceramic welding electrical penetration joint is used. The cavity formed between the ceramic welding electrical penetration joint I9 and the ceramic welding electrical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com