Aluminium casting locating cleaning device

A technology for positioning cleaning and aluminum casting, applied in cleaning methods and utensils, cleaning methods using liquids, chemical instruments and methods, etc., which can solve the problem of low flushing efficiency, inability to accurately align holes and grooves, and difficult debris and oil cleaning. Clean and other problems, to achieve the effect of cleaning and thoroughness, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Below in conjunction with accompanying drawing and embodiment the technical solution of the present invention is further described:

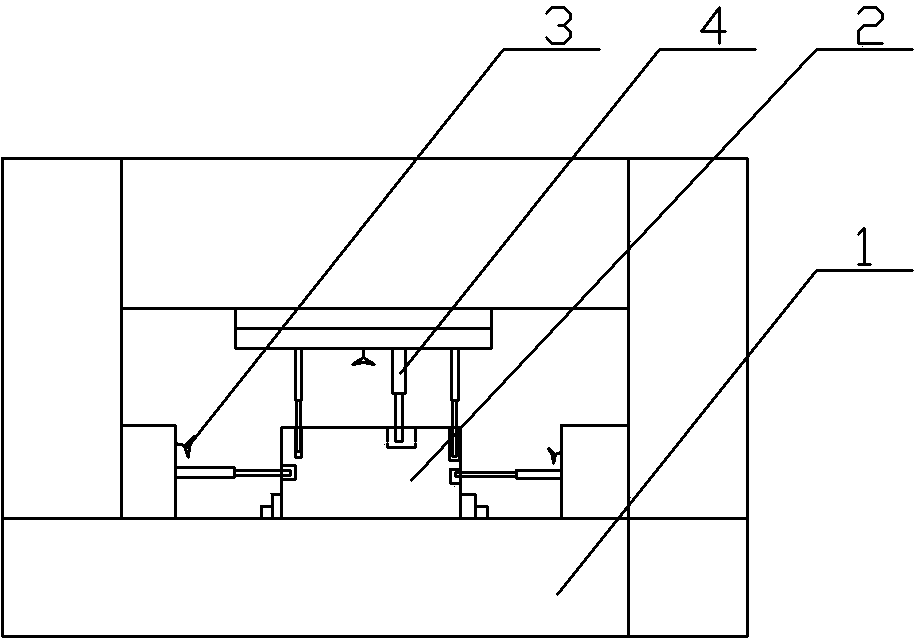

[0011] Such as figure 1 As shown, the present invention provides a positioning and cleaning device for aluminum castings, which includes a base 1 for positioning and installing a workpiece 2, a telescopic tube 4 corresponding to the hole groove of the workpiece, a cleaning fluid spray hole, and a cleaning fluid nozzle surrounding the workpiece 2 3. The cleaning liquid spray hole and the cleaning liquid nozzle 3 are connected to the cleaning circulation pump, and a solenoid valve is arranged on the circulation pump pipeline. The minimum distance is 5 mm. Considering the quality of the telescopic tube 4 and its harsh environment, avoid damage and corrosion of the telescopic tube 4. The telescopic tube 4 is made of at least two stainless steel tubes nested in a nest. It is preferred for shallow holes Two sections, three sections are preferr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com