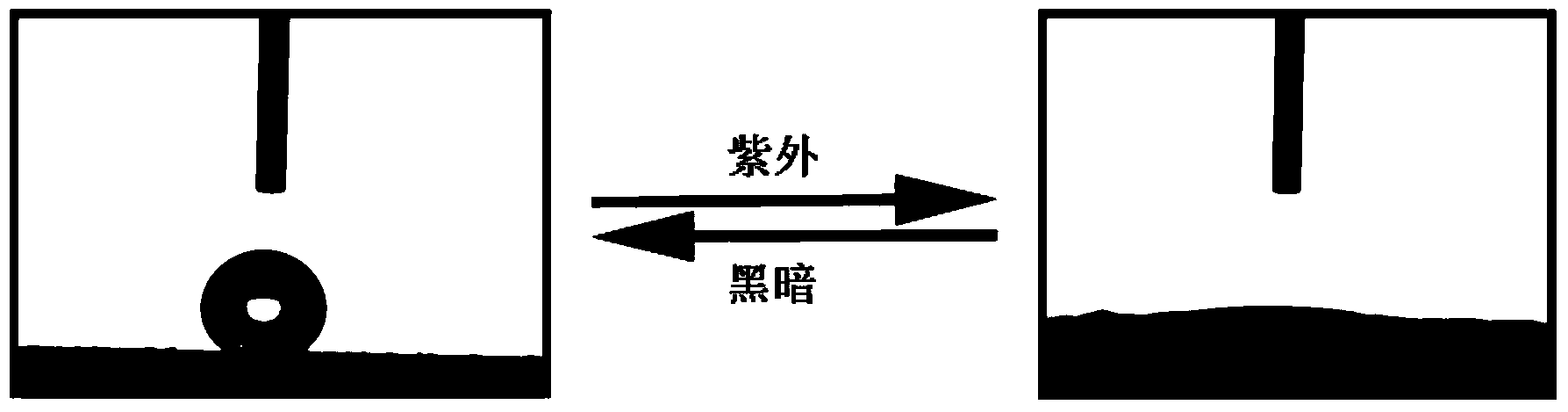

Method for preparing wood surface hydrophilicity-hydrophobicity reversible switch

A kind of wood surface, affinity and sparse technology, applied in wood treatment, wood processing equipment, wood treatment details, etc., can solve the problems of not having self-cleaning function, not being able to have hydrophilicity and hydrophobicity at the same time, and achieve good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

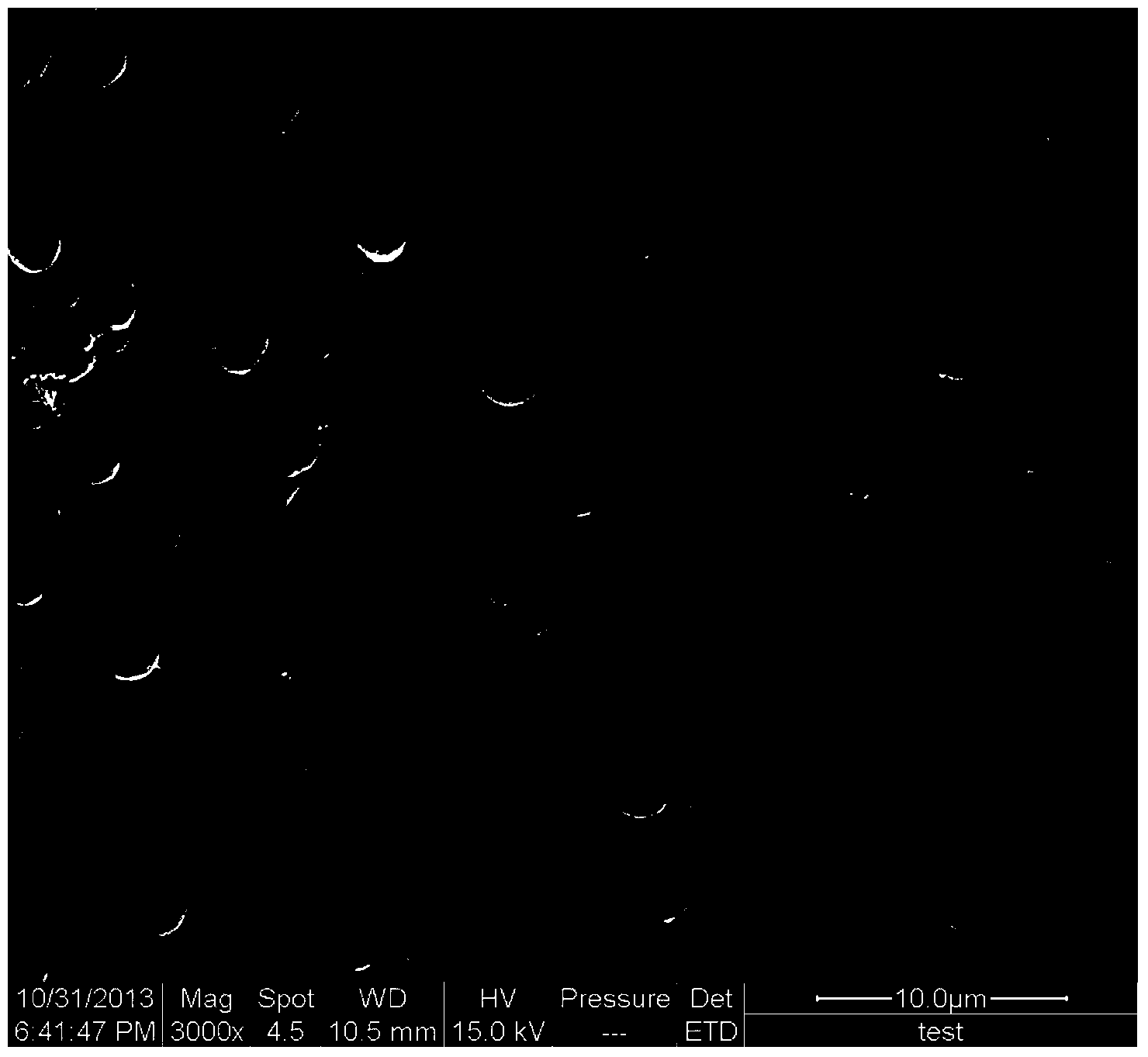

[0018] Embodiment 1: A method for preparing a wood surface reversible switch is carried out according to the following steps:

[0019] 1. Mix boric acid, ammonium fluotitanate and distilled water, and magnetically stir for 10-30 minutes to obtain a mixed solution, then add dropwise a hydrochloric acid solution with a mass percentage of 1%-10% to the mixed solution to adjust the pH to 1-7 or drop Add 0.5%-10% sodium hydroxide aqueous solution to a pH of 7-14, then place the wood in the pH-adjusted mixture, and react at a temperature of 50°C-180°C for 1h-24h. Wash the reacted wood with ionized water, and dry it at a temperature of 40°C to 80°C for 8h to 24h to obtain wood with a hydrophilic surface;

[0020] The molar mass concentration of boric acid in the mixed solution is 0.0001mol / L-11mol / L; the molar mass concentration of ammonium fluotitanate in the mixed solution is 0.0001mol / L-11mol / L;

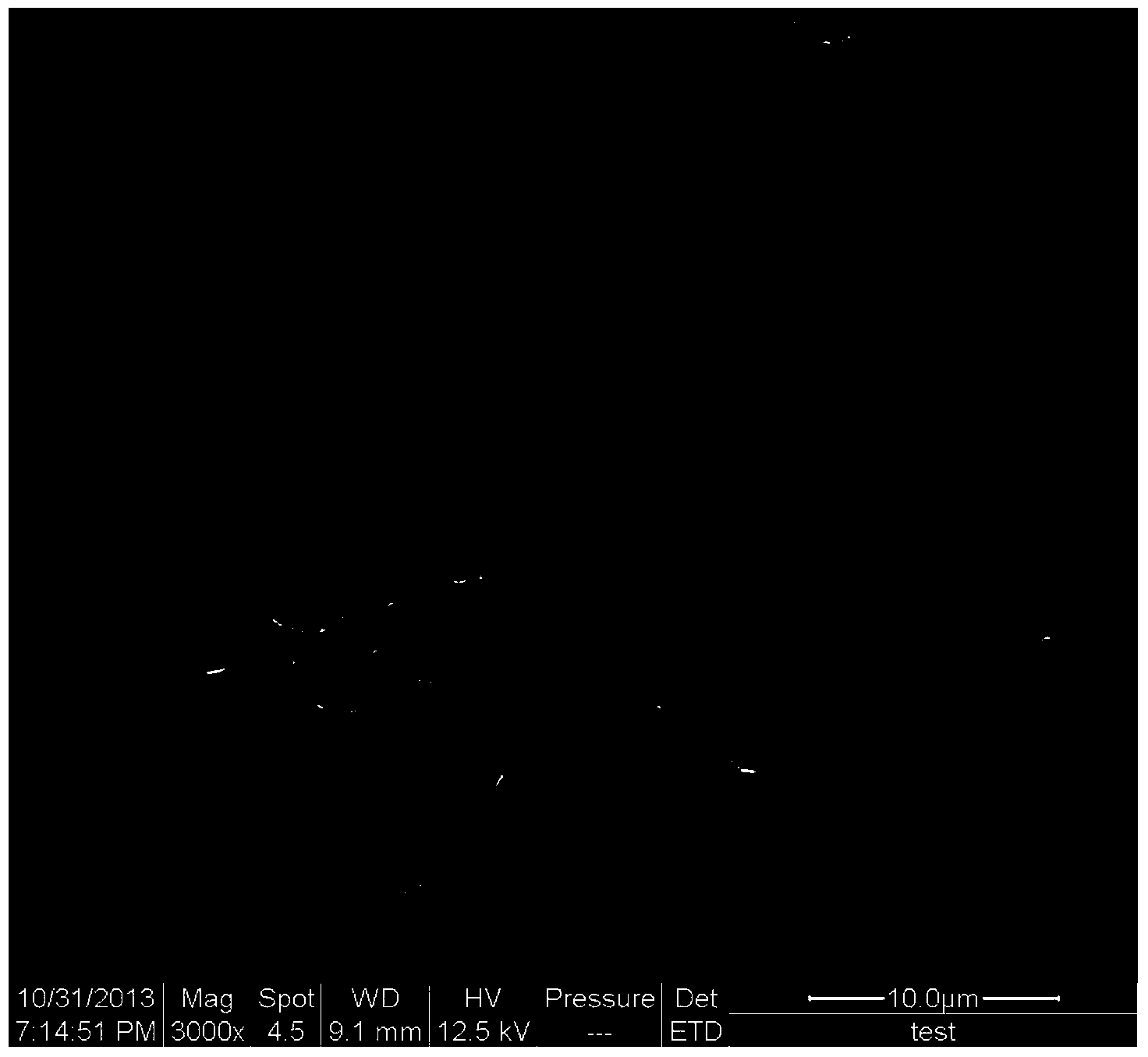

[0021] 2. Mix octadecyl trichlorosilane and absolute ethanol evenly, then put the w...

specific Embodiment approach 2

[0027] Embodiment 2: This embodiment is different from Embodiment 1 in that the wood described in step 1 is coniferous or broad-leaved. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0028] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: the molar mass concentration of boric acid in the mixed solution described in step one is 0.0001mol / L~10mol / L; The molar mass concentration of ammonium fluotitanate in the mixed solution is 0.0001mol / L-10mol / L. Others are the same as in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com