Equipment used for preparing continuous fabric reinforced thermoplastic resin

A thermoplastic resin, continuous fiber technology, applied in the field of polymer composite materials equipment, can solve the problems of difficult control of the specific process of impregnation, high die design cost, affecting production efficiency, etc., to ensure complete infiltration, easy operation, and production equipment. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

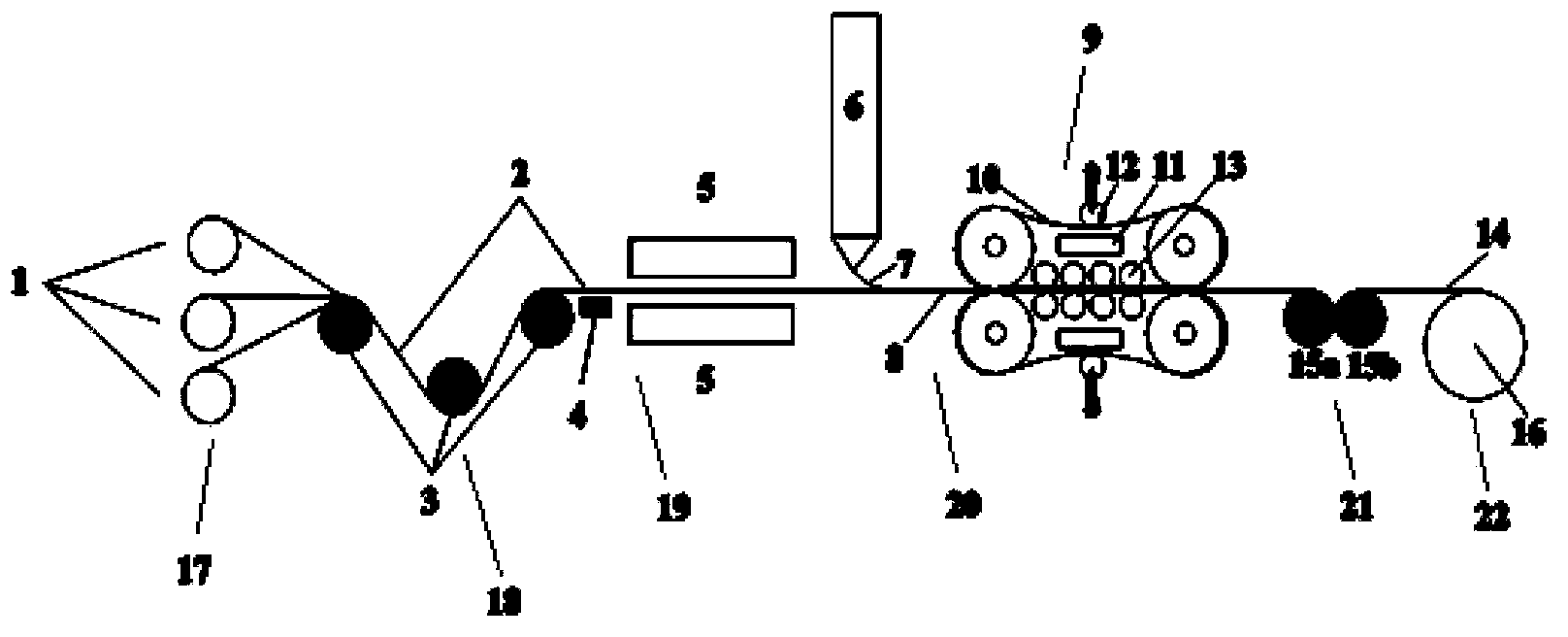

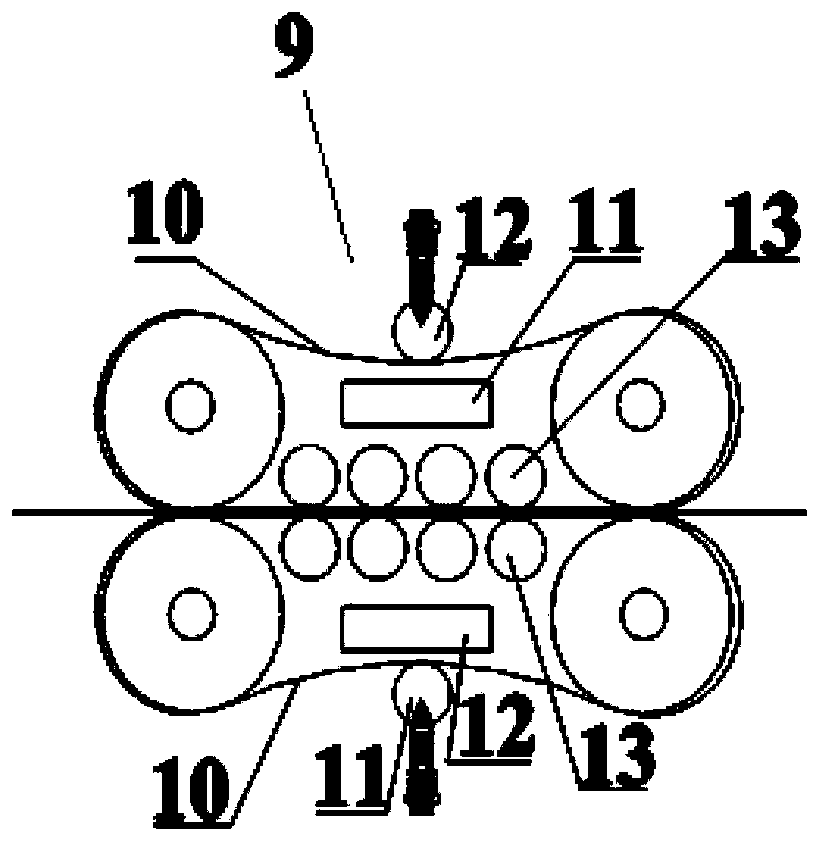

[0032] A device for making continuous fiber fabric reinforced thermoplastic resin, the structure of which is as follows figure 1 As shown, the equipment includes an unwinding component 17 , a tension control component 18 , a static elimination and preheating component 19 , a dipping component 20 , a cooling component 21 and a winding component 22 arranged in sequence.

[0033] The unwinding assembly 17: mainly includes the creel 1 or the unwinding roller, the creel 1 used in this embodiment, the continuous fiber fabric 2 of fixed width rests on the metal circular roller of the creel 1.

[0034] Tension control component 18: The continuous fiber fabric 2 on the creel 1 enters the tension control component 18, which is composed of three tension rollers 3 at a certain angle, and the three tension rollers 3 are evenly arranged according to the positions of the three vertices of an equilateral triangle , can better control the tension of the composite tape during the winding proces...

Embodiment 2

[0040] A device for making continuous fiber fabric reinforced thermoplastic resin, the device includes an unwinding component, a tension control component, a static elimination and preheating component, an impregnating component, a cooling component and a winding component arranged in sequence.

[0041] Wherein, the unwinding assembly is composed of a creel, on which the continuous fiber fabric with a fixed width is statically placed. Tension control component: It is composed of three tension rollers evenly arranged according to the positions of the three vertices of an equilateral triangle. The tension rollers can not only increase the tension of the continuous fiber reinforced fabric during the reproduction process, but also allow it to be evenly arranged in parallel to reduce fiber filaments Horizontal gaps between the bundles (continuous fiber tows) and making the surface of the fiber fabric smoother and flatter help avoid fluffing during the impregnation process and avoid ...

Embodiment 3

[0047] A device for making continuous fiber fabric reinforced thermoplastic resin, the device includes an unwinding component, a tension control component, a static elimination and preheating component, an impregnating component, a cooling component and a winding component arranged in sequence.

[0048] Wherein, the unwinding assembly is composed of a creel, on which the continuous fiber fabric with a fixed width is statically placed. Tension control component: It is composed of three tension rollers evenly arranged according to the positions of the three vertices of an equilateral triangle. The tension rollers can not only increase the tension of the continuous fiber reinforced fabric during the reproduction process, but also allow it to be evenly arranged in parallel to reduce fiber filaments Horizontal gaps between the bundles (continuous fiber tows) and making the surface of the fiber fabric smoother and flatter help avoid fluffing during the impregnation process and avoid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com