Treatment method for recycling oil-field oily sludge

A treatment method and a resource-recycling technology, which are applied in the field of oil-containing sludge recycling in oil fields, can solve the problems that oil and sediment are not easily peeled off, cannot be operated, and the extraction phase and sediment are not easily separated, so as to achieve easy separation, recovery and elimination. Environmental pollution, sufficient extraction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

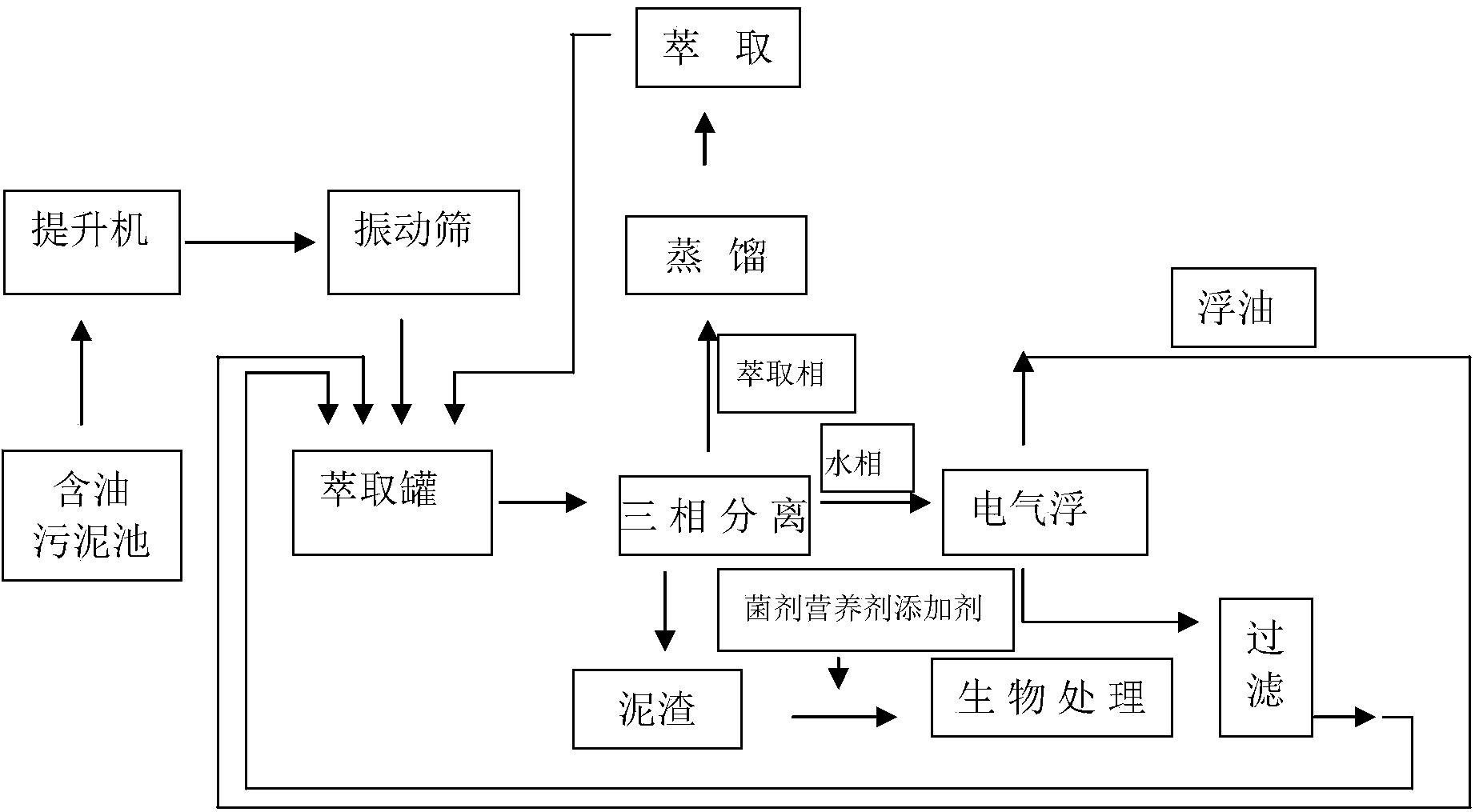

[0030] A treatment method for recycling oily sludge in oil fields, the treatment equipment includes an oily sludge lifting device, a vibrating screen, an extraction tank, a three-phase separation tank, a distillation tower, and an electric floating device;

[0031] Specific steps:

[0032] 1) The oily sludge lifting device lifts the oily sludge to the vibrating screen, and in the vibrating screen, lumps with a particle size greater than 0.5cm in the oily sludge are removed;

[0033] 2) Dilute oily sludge to 1 m 3 placed at 5 m 3 In the extraction tank, pump 1m 3 The extractant, stirred for 90min to completely dissolve the oil, inject 1m 3 After the oilfield produced water was stirred and settled for 10 minutes, the extraction phase was pumped into a three-phase separation tank to separate the solid phase, water phase, and oil phase; the extraction agent was 6 # A mixture of solvent oil as the main agent, and the extraction temperature is 35°C in a batch-type extraction met...

Embodiment 2

[0038] A treatment method for recycling oily sludge in oil fields, the treatment equipment includes an oily sludge lifting device, a vibrating screen, an extraction tank, a three-phase separation tank, a distillation tower, and an electric floating device;

[0039] Specific steps are as follows:

[0040] 1) The oily sludge lifting device lifts the oily sludge to the vibrating screen, and in the vibrating screen, lumps with a particle size greater than 0.5cm in the oily sludge are removed;

[0041] 2) Dilute oily sludge to 1m 3 put in 1 # In the extraction tank, pump into 2m 3 extractant, stir to dissolve the oil completely, inject 1 m 3After producing water from the oilfield and stirring and settling for 10 minutes, the extraction phase is pumped into a three-phase separation tank to separate the solid phase, water phase, and oil phase; the extraction agent is a mixture of oilfield condensate oil and petroleum ether as the main agent. The extraction process adopts a batch m...

Embodiment 3

[0046] A treatment method for recycling oily sludge in oil fields, the treatment equipment includes an oily sludge lifting device, a vibrating screen, an extraction tank, a three-phase separation tank, a distillation tower, and an electric floating device;

[0047] Specific steps are as follows:

[0048] 1) The oily sludge lifting device lifts the oily sludge to the vibrating screen, and in the vibrating screen, lumps with a particle size greater than 0.5cm in the oily sludge are removed;

[0049] 2) Dilute oily sludge to 1 m 3 Put in 1# extraction tank, pump into 3m 3 The extractant, stirred for 50min to completely dissolve the oil, injected 3 m 3 The oil field produces water, and after settling for 60min, the extract phase is pumped into the three-phase separation tank to separate the solid phase, water phase and oil phase; the extractant is 6 # The mixture of solvent oil, aromatic hydrocarbons and oil field condensate oil as the main agent, the extraction process adopts ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com