Strengthened dolomite pottery blank mud

A white cloud and pottery blank technology, applied in the field of white cloud pottery blank mud, can solve the problems of high glaze firing temperature, many blank glaze bonding defects, unstable process indicators of blank glaze adaptability, etc., and achieve the effect of offsetting stress contrast

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

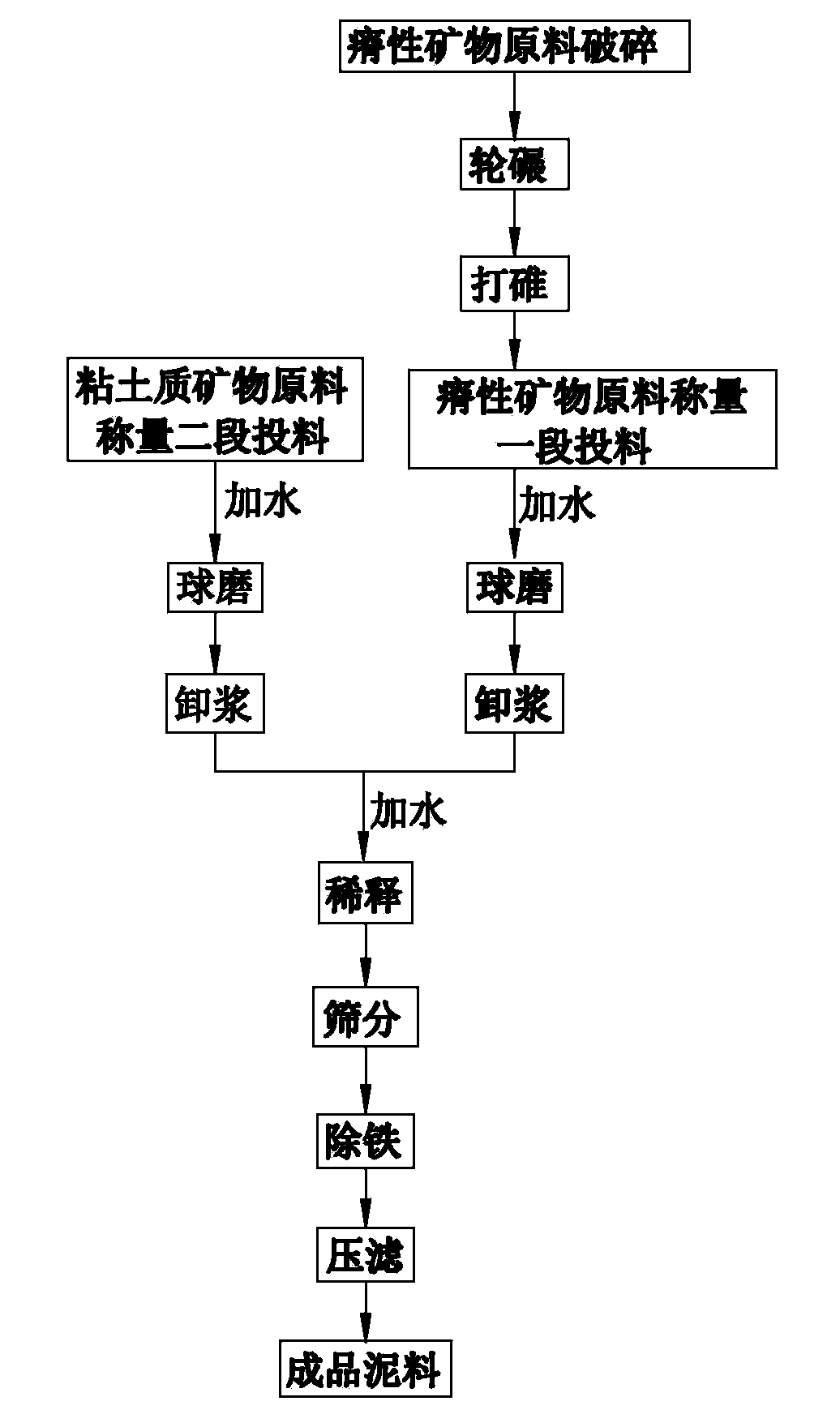

Method used

Image

Examples

Embodiment approach 1

[0023] Strengthen the mud of Baiyun pottery, the mud preferably includes the following components by weight percentage: 65% SiO 2 , 12.7% Al 2 o 3 , 8.5% MgO, 5.0% CaO, 1.5% K 2 O, 0.6% Na 2 O, 5.8% loss on ignition and a small amount of Fe 2 o 3 、TiO 2 and other impurities. SiO in formulation 2、Al 2 o 3 , MgO, CaO, K 2 O, Na 2 O and other chemical components can be introduced through natural mineral raw materials such as kaolin, ball clay, magnesia clay, bentonite, porcelain stone, talc, tremolite, diopside, wollastonite, potassium, and albite. Among them, kaolin, ball clay, magnesia clay, bentonite, etc. can also contribute to the forming of mud mud, such as plasticity and cohesiveness.

[0024] The strengthened white cloud pottery mud of the present invention has a glaze firing temperature of 1080±10°C. The mud expansion coefficient is controlled at β200~230×10 —6 In the range of / ℃, the expansion coefficient range of the glaze is β170~200×10 —6 / °C, the fire...

Embodiment approach 2

[0026] Strengthen the white cloud pottery mud, the mud mud includes subordinate components by weight percentage: 69.8% SiO 2 , 11.6% Al 2 o 3 , 6.0% MgO, 6.9% CaO, 1.3% K 2 O, 0.5% Na 2 O, 3.5% loss on ignition and a small amount of Fe 2 o 3 、TiO 2 and other impurities. SiO in formulation 2 、Al 2 o 3 , MgO, CaO, K 2 O, Na 2 Chemical elements such as O can be introduced through natural mineral raw materials such as kaolin, ball clay, magnesia clay, bentonite, porcelain stone, talc, tremolite, diopside, wollastonite, and potassium albite feldspar.

Embodiment approach 3

[0028] Strengthen the mud of Baiyun pottery, which includes the following components by weight percentage: 60.7% SiO 2 , 14.7% Al 2 o 3 , 6.1% MgO, 8.0% CaO, 2.1% K 2 O, 0.8% Na 2 O, 7.0% loss on ignition and a small amount of Fe 2 o 3 、TiO 2 and other impurities. SiO in formulation 2 、Al 2 o 3 , MgO, CaO, K 2 O, Na 2 Chemical elements such as O can be introduced through natural mineral raw materials such as kaolin, ball clay, magnesia clay, bentonite, porcelain stone, talc, tremolite, diopside, wollastonite, and potassium albite feldspar.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com