Method for preparing sugarcane top polysaccharide from sugarcane tops

A technology of cane tip and polysaccharide is applied in the field of using sugarcane tip to prepare sugarcane tip polysaccharide, which can solve the problems of long extraction time, long process line, influence efficiency, etc., and achieves the advantages of short extraction time, improving polysaccharide yield and solving resource waste. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below in conjunction with specific embodiments and accompanying drawings.

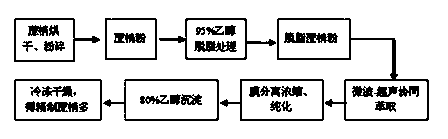

[0030] The present invention adopts microwave-ultrasonic combined method to extract sugarcane tip polysaccharide, which has high efficiency and saves time. The process circuit diagram is as attached figure 1 , the specific process is as follows:

[0031] 1) Fresh cane shoots are crushed into small pieces with a multi-functional new grass breaker, dried at 50°C, crushed by a high-speed grinder, and passed through a 80-mesh sieve to obtain sugarcane shoot powder;

[0032] 2) Degreasing pretreatment of sugarcane shoot powder: add 95% ethanol to the sugarcane shoot powder, extract at 80°C for 1 hour, remove the lipids outside the cell wall of the sugarcane shoot and the pigment impurities in the sugarcane shoot, remove the solvent, and leave the defatted sugarcane shoot powder to wait use;

[0033] 3) The degreased sugarcane tip powder in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com