Low compression set liquid silastic and preparation method thereof

A technology of liquid silicone rubber and permanent deformation, which is applied in the field of addition-type liquid silicone rubber. It can solve the problems of low hardness and dimensional stability, and cannot meet low compression permanent deformation at the same time, so as to improve compression permanent deformation, low hardness and low hardness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

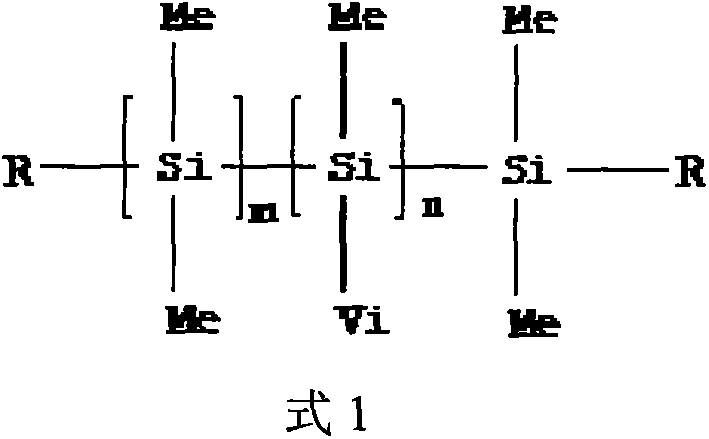

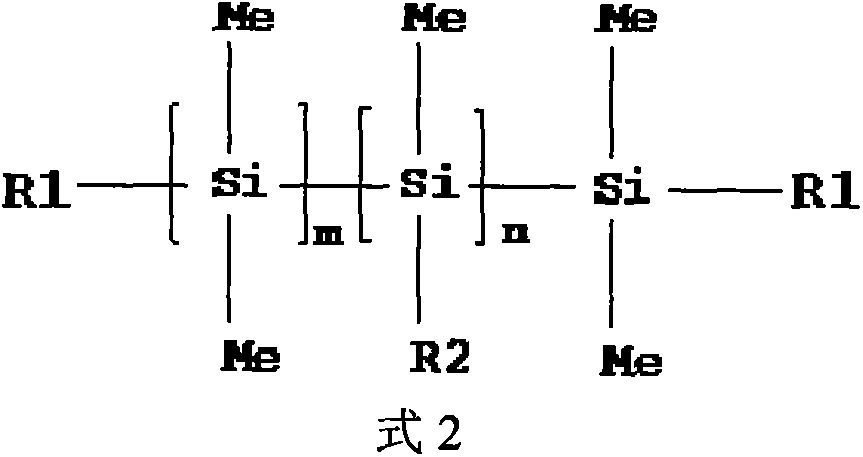

Method used

Image

Examples

Embodiment 1

[0037] Basic rubber formula (1):

[0038] formula

Vinyl polysiloxane

filler

Auxiliary

Types of

Viscosity 50,000 centipoise Vinyl content 0.8%

Hexamethyldisilazane

Fraction

100

30

6

[0039] Liquid silicone rubber formula:

[0040] formula

Embodiment 2

[0042] Basic rubber formula:

[0043] formula

Vinyl polysiloxane

filler

Auxiliary

Types of

Viscosity 50,000 centipoise Vinyl content 0.8%

Hexamethyldisilazane

Fraction

100

40

8

[0044] Liquid silicone rubber formula:

[0045] formula

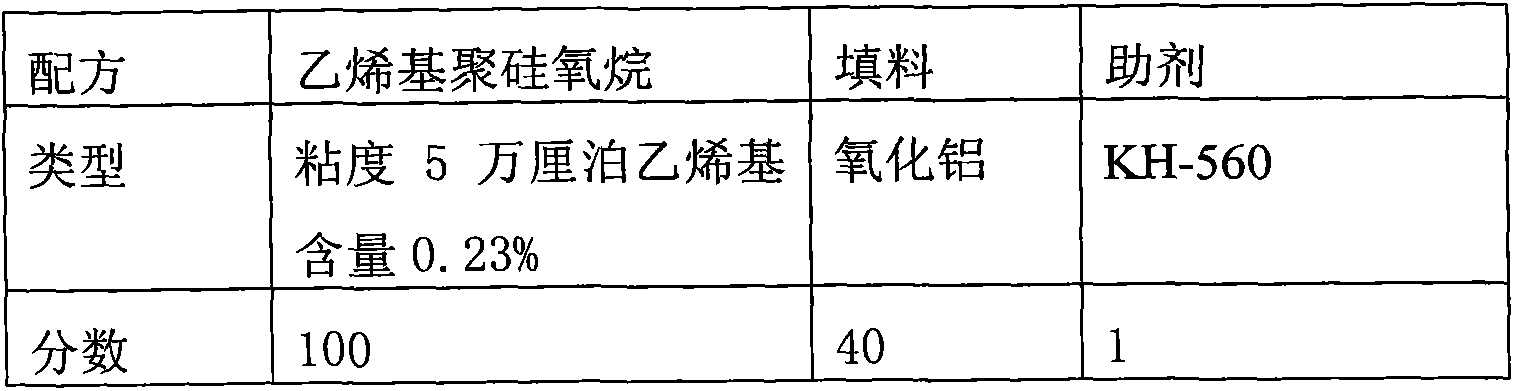

Embodiment 3

[0047] Basic rubber formula:

[0048] formula

Vinyl polysiloxane

filler

Auxiliary

Types of

Viscosity 50,000 centipoise Vinyl content 0.8%

Aluminum oxide

KH-560

Fraction

100

40

1

[0049] Liquid silicone rubber formula:

[0050] formula

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com