Method for producing disperse red 343

A technology of disperse red and products, applied in chemical instruments and methods, preparation of azo dyes, azo dyes, etc., can solve the problems of difficult wastewater treatment, large amount of wastewater, low yield, etc., and reduce energy consumption and dust Pollution, the effect of eliminating heavy metal ion pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

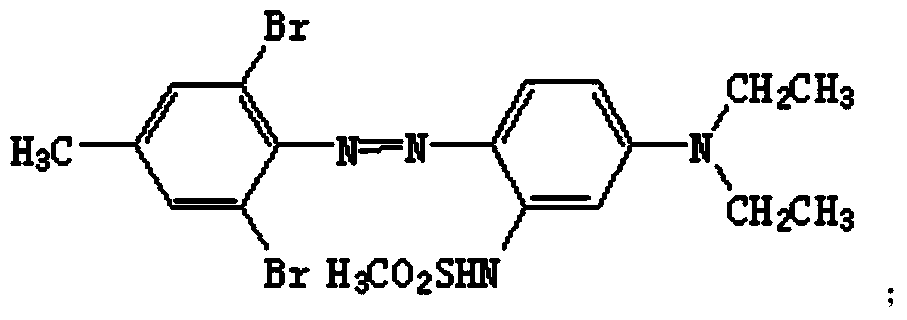

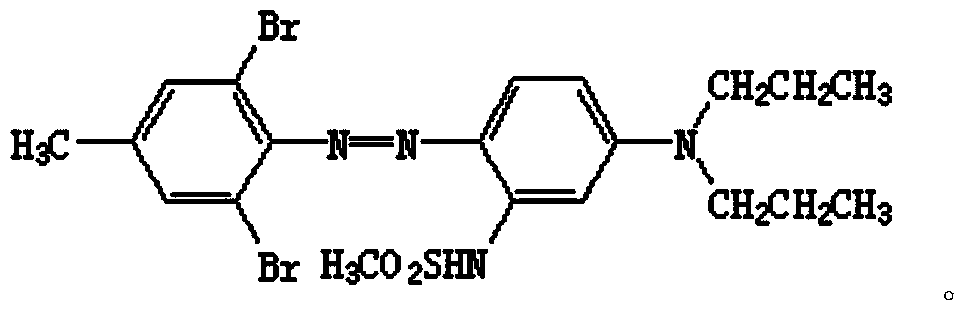

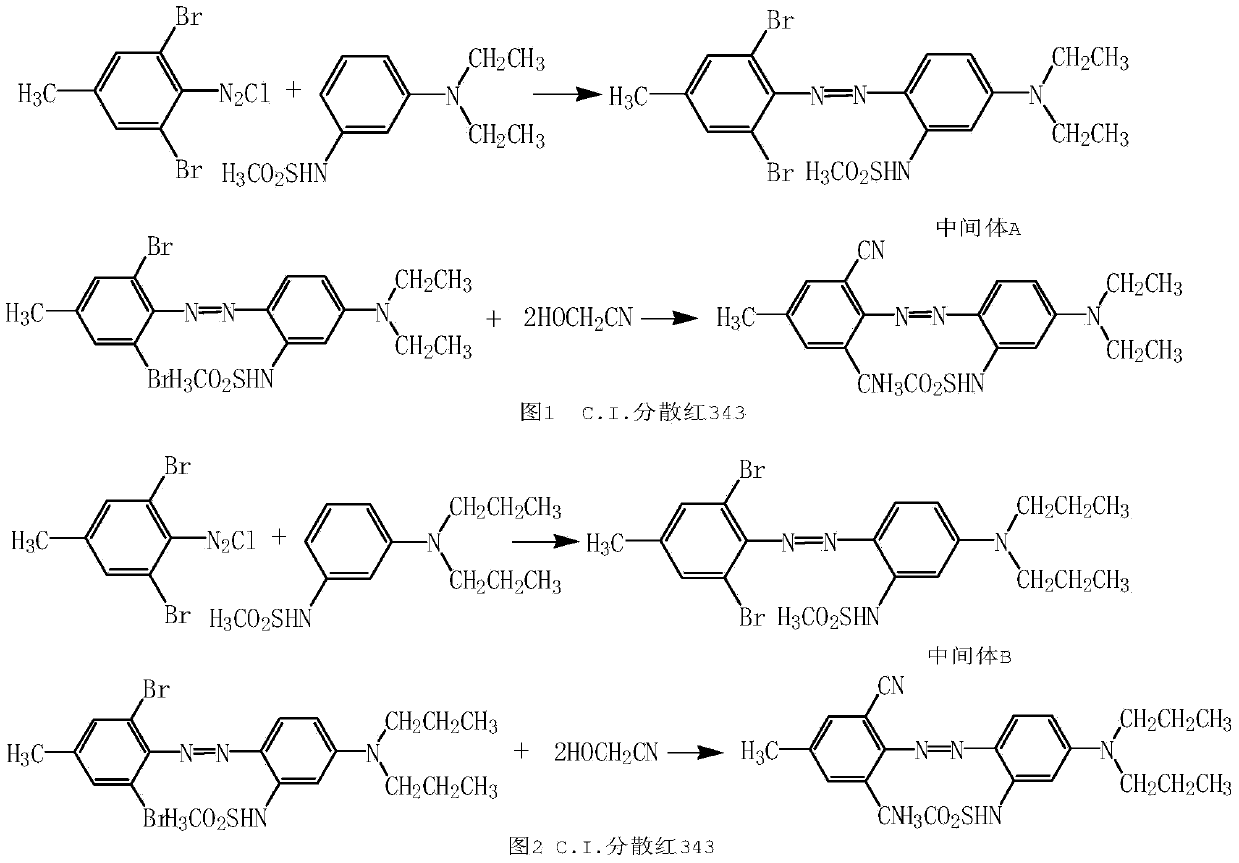

Image

Examples

Embodiment 1

[0014] Example 1: In a 250mL flask, add 10.6g of Intermediate A, 53g of toluene, 21.2g of water, 0.21g of dodecyltrimethylammonium bromide, 0.02g of copper salt catalyst, 3.42g of cyanohydrin, A few grams of acidic acid agent, at 100°C, TLC detects that the reaction is complete, filters, washes to remove salt, and washes again to obtain 8.22g of the product, with a yield of 98%.

Embodiment 2

[0015] Example 2: In a 250mL flask, add 11.6g of Intermediate A, 58g of toluene, 23.2g of water, 0.23g of dodecyltrimethylammonium bromide, 0.02g of copper salt catalyst, 3.42g of cyanohydrin, A few grams of acid agent, at 100 ° C, TLC detection of the end of the reaction, filtered, washed to remove salt, and then washed to obtain 8.82 g of the product, with a yield of 96%.

Embodiment 3

[0016] Example 3: In a 250mL flask, add 10.6g of Intermediate B, 45g of toluene, 18.2g of water, 0.1g of dodecyltrimethylammonium bromide, 0.01g of copper salt catalyst, 2.42g of cyanohydrin, Some g of acid-forwarding agent, at 110°C, TLC detected that the reaction was completed, filtered, washed to remove salt, and washed again to obtain 7.89g of the product, with a yield of 94%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com