Patents

Literature

44 results about "Copper(I) cyanide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Copper(I) cyanide is an inorganic compound with the formula CuCN. This off-white solid occurs in two polymorphs; impure samples can be green due to the presence of Cu(II) impurities. The compound is useful as a catalyst, in electroplating copper, and as a reagent in the preparation of nitriles.

Preparation method for 2-nitro-4-(trifluoromethyl)benzonitrile

InactiveCN105175282AHigh selectivityImprove conversion rateOrganic-compounds/hydrides/coordination-complexes catalystsPreparation by cyanide reactionPotassium cyanideReaction temperature

The invention provides a preparation method for 2-nitro-4-(trifluoromethyl)benzonitrile. The method comprises the following steps: under the protection of nitrogen, successively adding 3-nitro-4-chlorobenzotrifluoride, cyanide, a catalyst II, a catalyst II and a solvent N-methyl-2-pyrrolidone into a reactor; carrying out heating under mechanical stirring; carrying out a reaction at temperature of 185 to 195 DEG C for 5 to 9 h; and then carrying out rectification so as to obtain 2-nitro-4-(trifluoromethyl)benzonitrile. The cyanide is one or more selected from the group consisting of sodium cyanide, potassium cyanide and cuprous cyanide; the catalyst I is one or two selected from the group consisting of cuprous bromide and nickel bromide; and the catalyst II is methylimidazole ionic liquid. According to the preparation method in the invention, the two catalysts are used and reaction temperature is adjusted in stages, so selectivity and conversion rate of the reaction are improved, cost is substantially reduced, and the preparation method is simple.

Owner:青岛和兴精细化学有限公司 +1

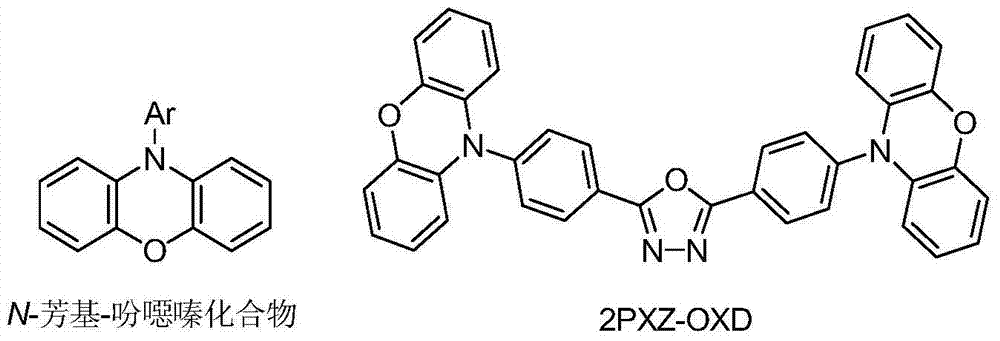

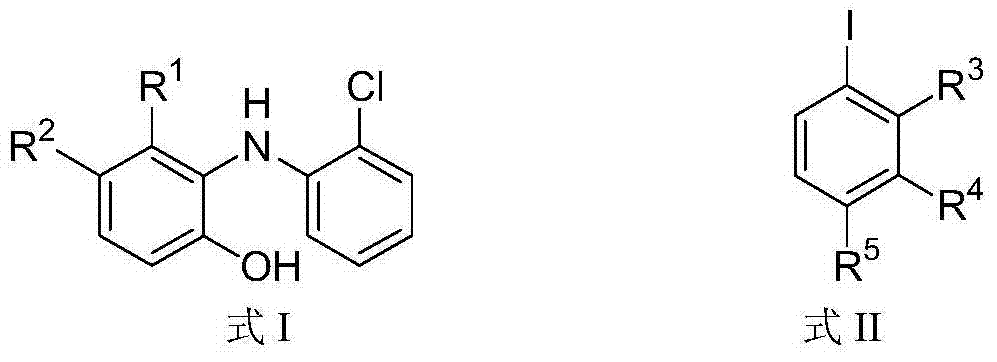

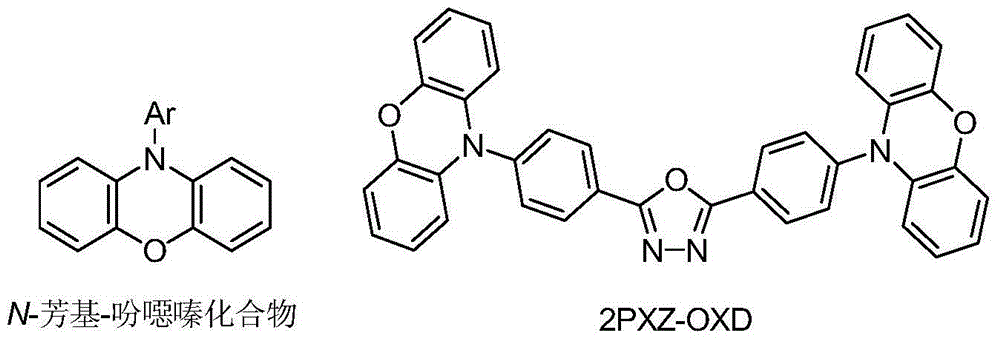

Method for synthesizing N-aryl-phenoxazine compounds

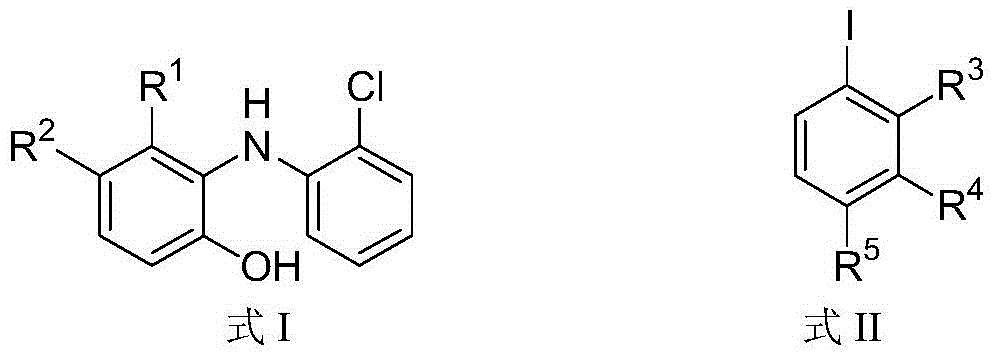

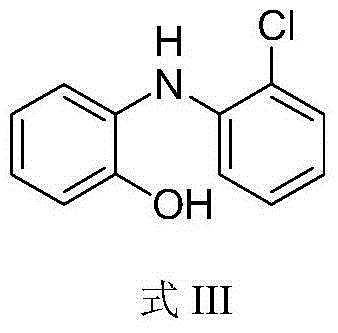

ActiveCN103819423AEfficiently control the sequence of cascade reactionsControlling the order of cascade reactionsOrganic chemistryChemical synthesisSolvent

The invention discloses a method for synthesizing N-aryl-phenoxazine compounds, and belongs to the chemical synthesis filed. The method comprises the following steps: taking a compound represented by the formula I, which is shown in the description, as the raw materials; mixing the compound with a solvent, a catalyst, and an alkali reagent, adding an arylation agent, and carrying out reactions at a temperature of 50 to 250 DEG C so as to obtain the target product; wherein the solvent is amides, benzenes, or nitriles; the catalyst is copper halide, cuprous halide, alkyl copper carboxylate, alkyl copper carboxylate hydrate, aryl copper carboxylate, cuprous oxide, or cuprous cyanide; and the arylation agent is iodobenzenes represented by formula II, which is shown in the description, mono-substituted iodopyridine, or 3-iodothiophene. The method has the advantages of simple reaction steps and high yield of target product.

Owner:JIANGSU AOLUNDA HIGH TECH IND

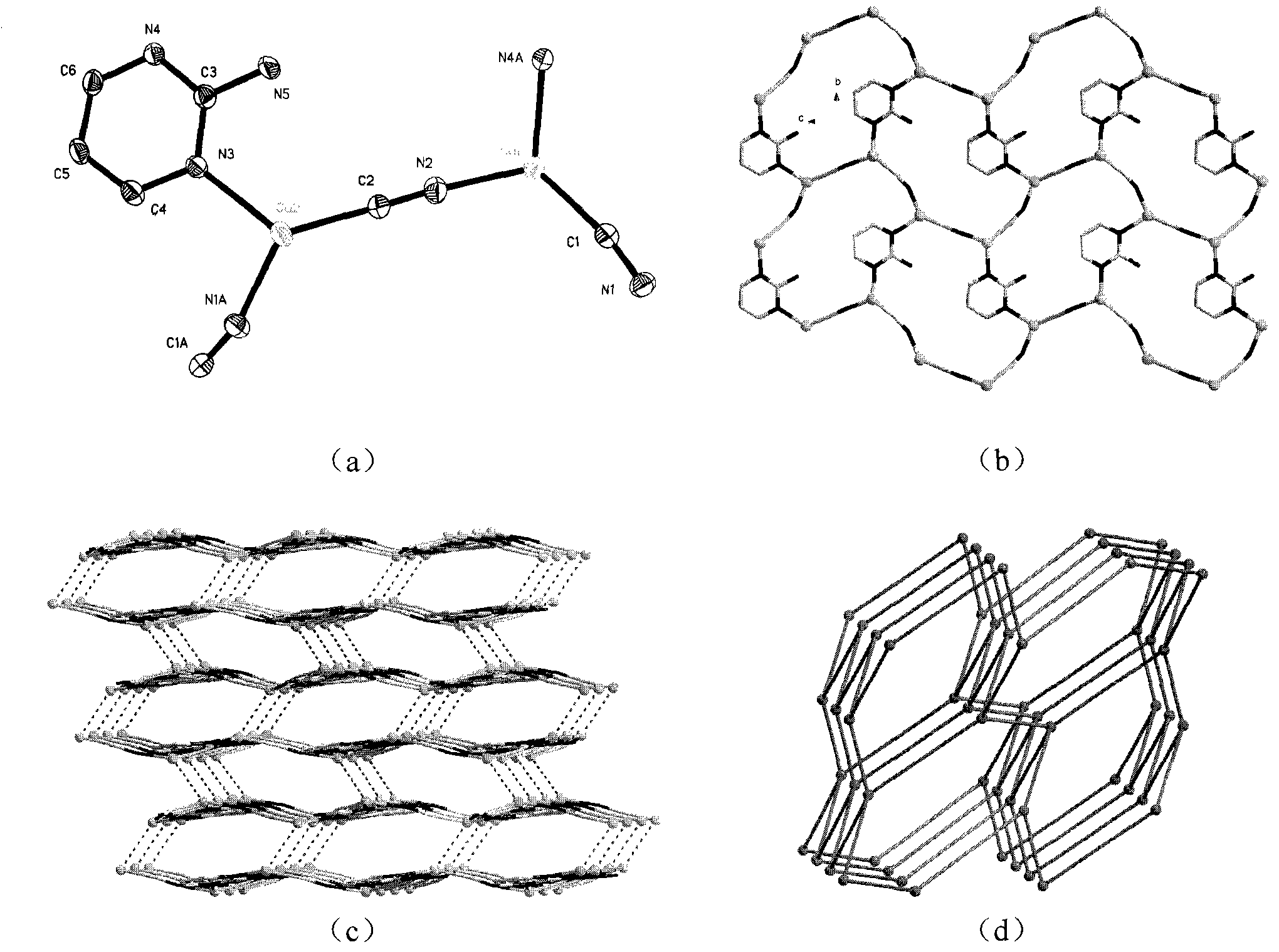

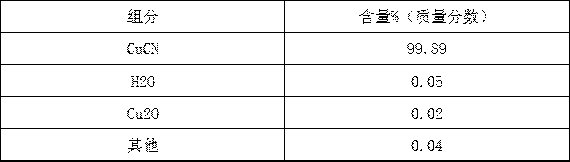

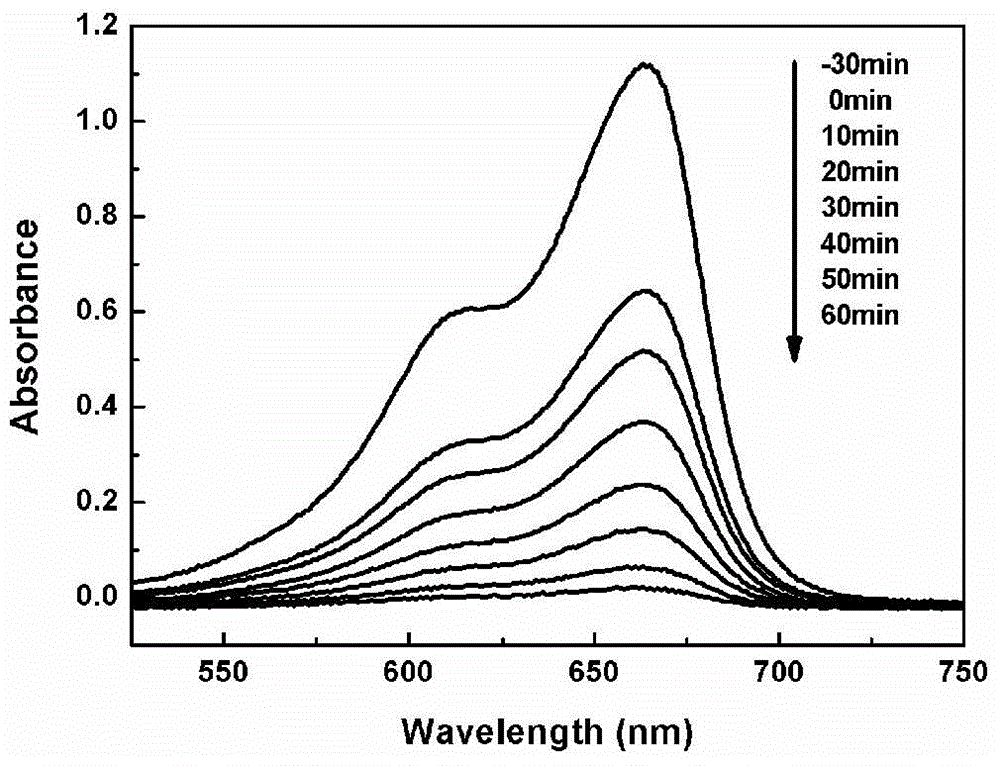

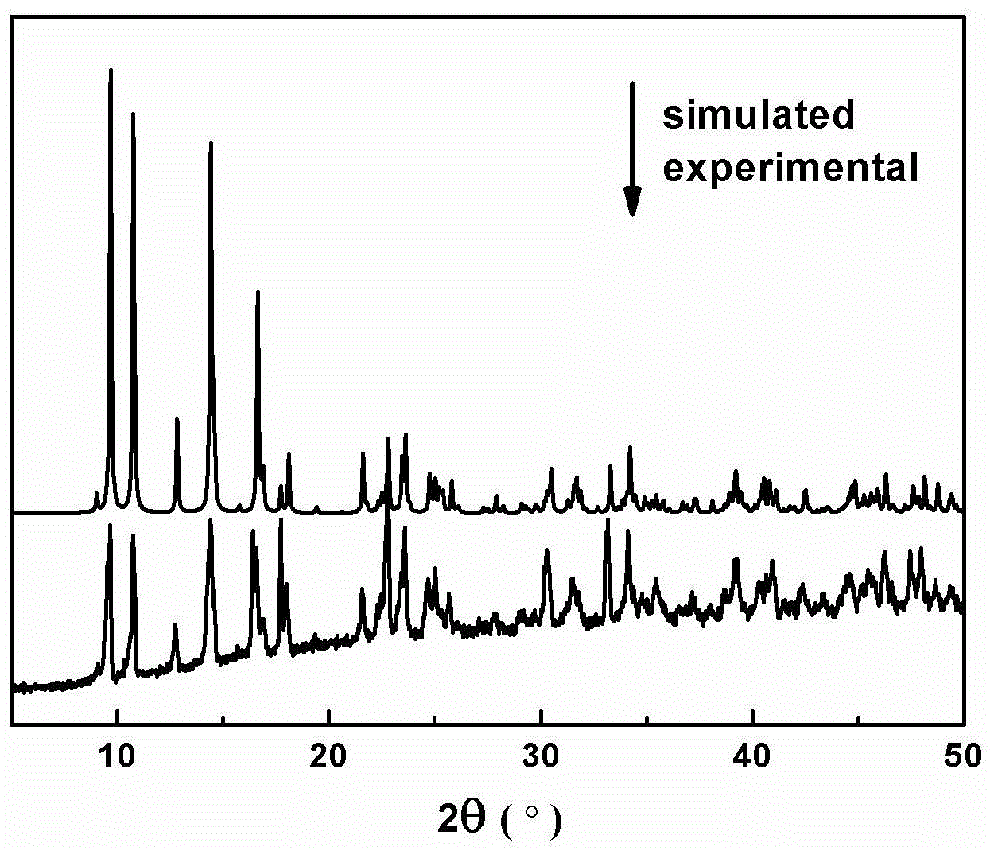

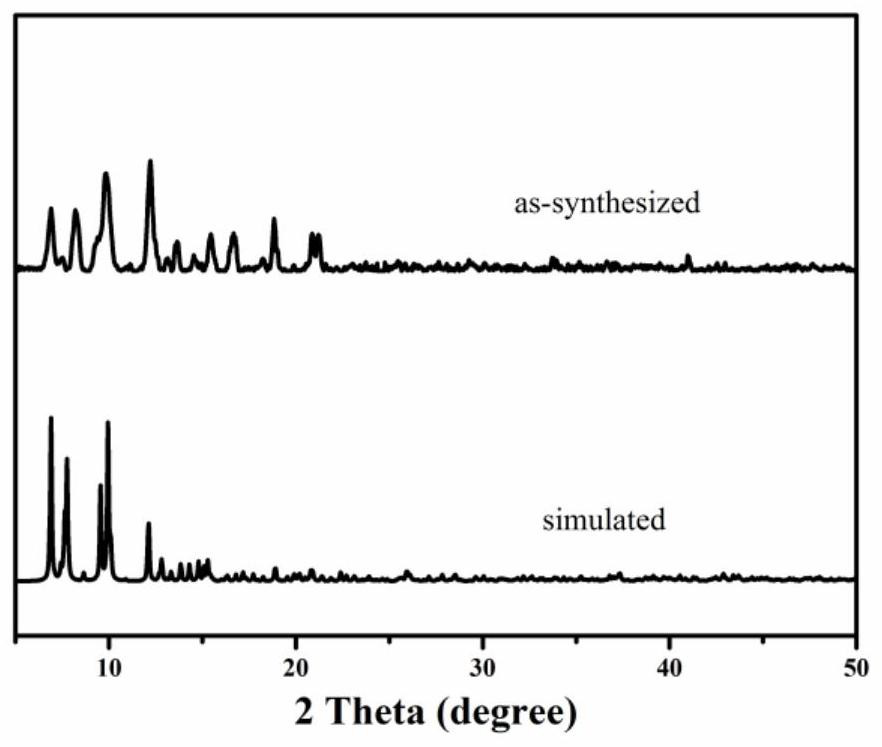

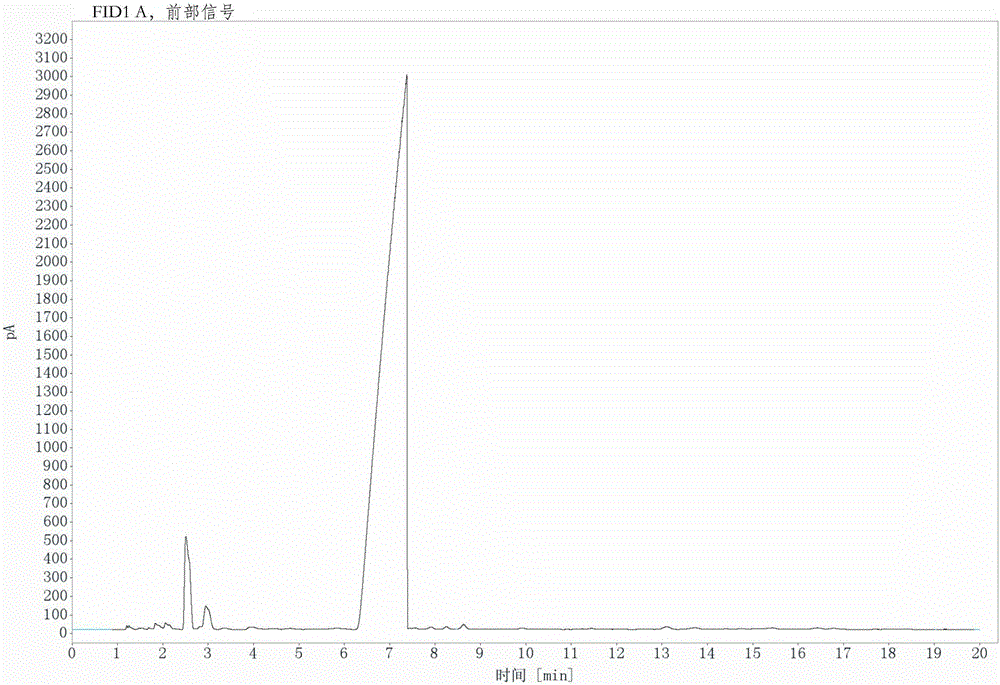

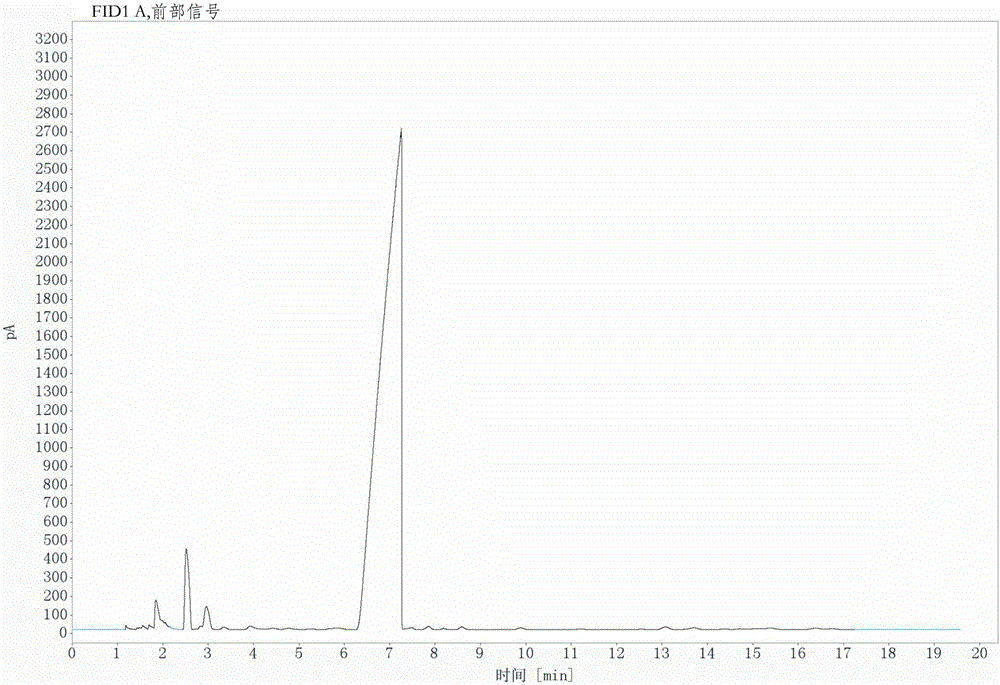

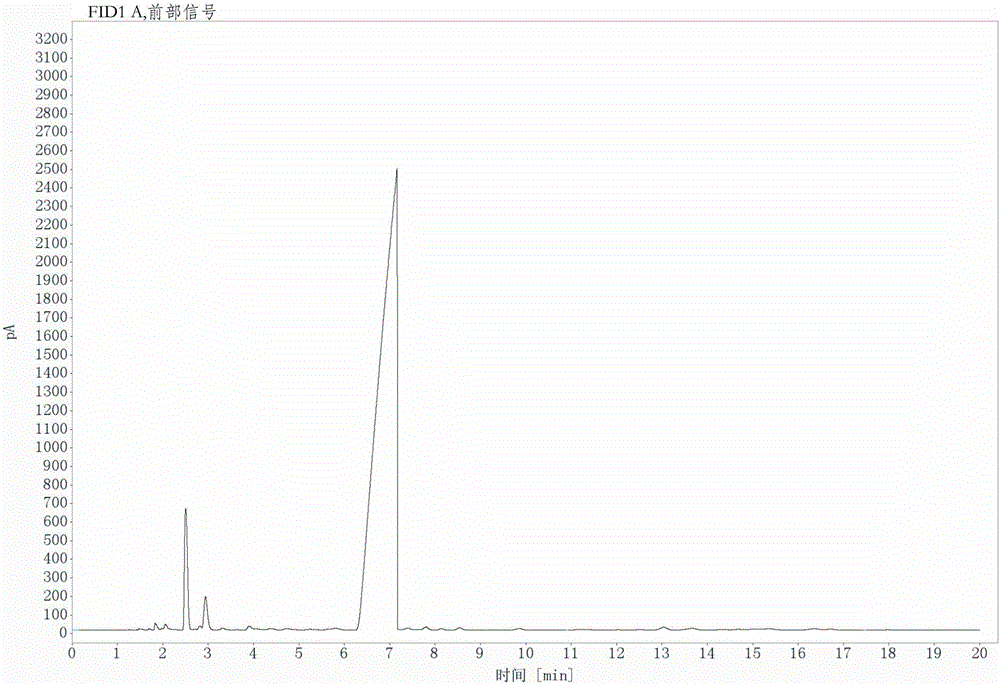

Preparation method of crystal material [WS4Cu4(CN)2(TPP) (2, 3, 5, 6-4-tetra-pyridyl pyrazine)] with high detection sensitivity for TNP (2, 4, 6-trinitrophenol)

InactiveCN107904655AHigh yieldGood chemistryPolycrystalline material growthFrom normal temperature solutionsN dimethylformamideFiltration

The invention discloses a preparation method of a crystal material [WS4Cu4(CN)2(TPP) (2, 3, 5, 6-4-tetra-pyridyl pyrazine)] with high detection sensitivity for TNP (2, 4, 6-trinitrophenol). The preparation method comprises the following steps: adding ammonium tetrathiotungstate, ammonium thiocyanate, cuprous cyanide and 4-(4-pyridyl) methylene amino-1, 2, 4-triazole into a mixed solvent acetonitrile and N, N-dimethylformamide at a certain ratio and stirring the mixture, so as to obtain a uniform turbid liquid; transferring the uniformly stirred turbid liquid into a reaction kettle for airtightheating to a certain temperature for a few days, slowly reducing the temperature to a room temperature, performing suction filtration, washing and drying, so as to obtain the crystal material [WS4Cu4(CN)2(TPP)]. The preparation method has the advantage that the crystal material [WS4Cu4(CN)2(TPP)] with high detection sensitivity for the TNP is obtained.

Owner:JIANGNAN UNIV

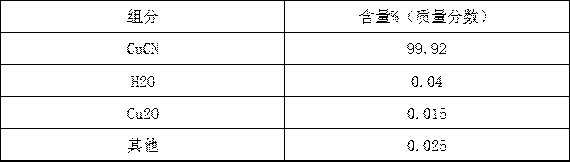

Preparation method of crystal material {[NH4][TbCu(ina)4(CN)].2DMF}n with function of selectively adsorbing organic dye

InactiveCN105903440AImprove adsorption capacityGood chemistryPolycrystalline material growthFrom normal temperature solutionsFiltrationOrganic dye

The invention discloses a preparation method of a crystal material {[NH4][TbCu(ina)4(CN)].2DMF}n with the function of selectively adsorbing organic dye. The method comprises the steps that hydrogen sulfide is introduced into an ammonia solution of tungstic acid for a reaction, and suction filtration and drying are carried out to obtain ammonium tetrathiotungstate; the ammonium tetrathiotungstate and cuprous cyanide are added into N,N'-dimethyl formamide and stirred to obtain an orange red solution; isonicotinic acid is added into the obtained orange red solution, stirring is performed, ammonium hydroxide is dropwise added, the mixture is filtered after being completely dissolved, an acetonitrile solution containing terbium nitrate is added to the upper layer of filtrate, crystallization, filtration, washing and drying are performed, and therefore the crystal material {[NH4][TbCu(ina)4(CN)].2DMF}n is obtained. The preparation method has the advantage that the crystal material {[NH4][TbCu(ina)4(CN)].2DMF}n with the function of selectively adsorbing the organic dye is obtained.

Owner:JIANGNAN UNIV

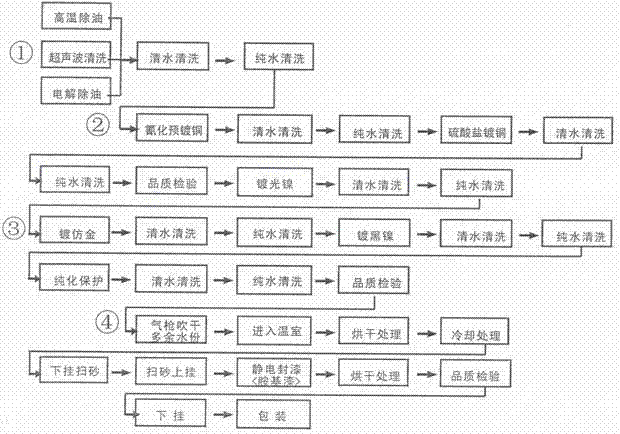

Antique paint electroplating process

InactiveCN102787334AIncrease contentUniform and moderate thicknessCooking & bakingAdditive ingredient

The invention discloses an antique paint electroplating process. The process adopts a rack plating process and comprises the following steps of: A, cleaning and processing a product: high-temperature degreasing, ultrasonic cleaning and electrolytic degreasing; B, underlying process: cyaniding pre-coated copper and cupric sulfate, and plating nickel; C, middle layer processing: plating imitated gold and black nickel, purification and protection: and D, baking, sweeping sand, and carrying out static sealed paint protection treatment. In the invention, the content of zinc oxide and cuprous cyanide are adjusted in a procedure of plating the imitated gold according to the requirements of required antique effect, so that the product achieves the ideal antique effect. Furthermore, proper electroplating conditions such as ingredients, temperature, time and the like of electroplate liquid are prepared in each procedure, so that the thickness of the electroplating layer is uniform and proper; the appearance of the coating is bright; the processing precision is high; the corrosion resistance is high; and volume production can be achieved. The antique paint electroplating process can be widely applied to electroplating process of various products.

Owner:ZHONGSHAN SENQIU LIGHTING

Method for silvering aluminum and aluminum alloy

InactiveCN104233296ALiquid/solution decomposition chemical coatingSuperimposed coating processCopper platingCopper(I) cyanide

The invention provides a method for silvering aluminum and aluminum alloy, and belongs to the technical field of metal plating. The method for silvering aluminum and aluminum alloy is achieved by the following technical scheme: (1) carrying out chemical zinc immersion on an aluminum part in a zinc dipping solution, removing surface oxides of the aluminum part, and simultaneously replacing a layer of thin and dense zinc coating; (2) timely transferring the aluminum part after zinc immersion into a cyanide copper plating process, wherein the cuprous cyanide in a cyanide plating solution is high in content, and a work-piece is connected with a cathode of a power supply, carrying out flash plating for 1-2 minutes by using current which is 3-5 times greater than normal current, and then plating for 40-60 minutes at normal current; and (3) silvering after copper plating, electrifying and putting in a slot, impacting for 1-2 minutes by using current of 0.6-1.0A / dm<2>, and reducing the current to 0.3-0.4A / dm<2>. The coating obtained by the method disclosed by the invention is bright and silver in surface, and has fine crystal and uniform appearance.

Owner:ZHENJIANG JIANGCHENG METAL PROD

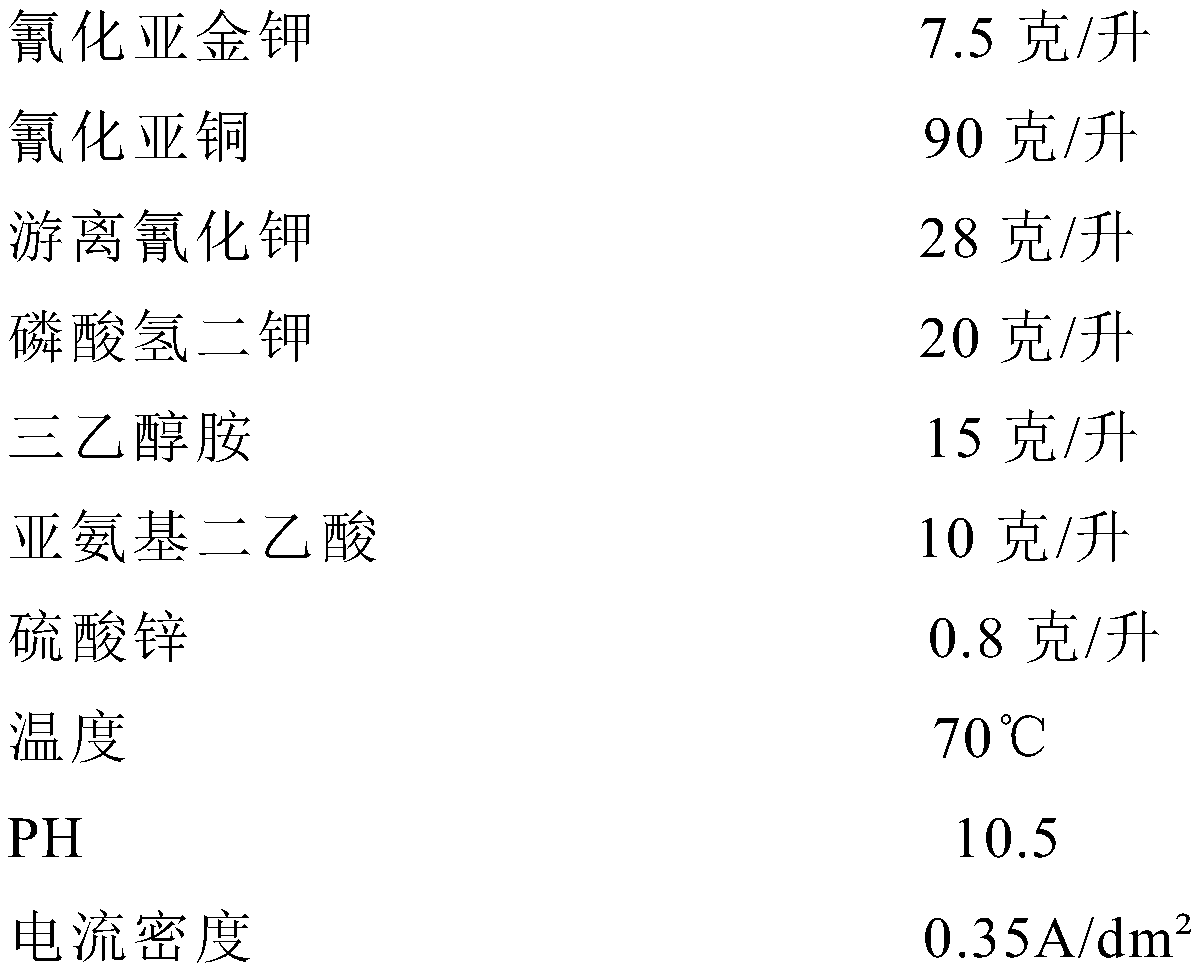

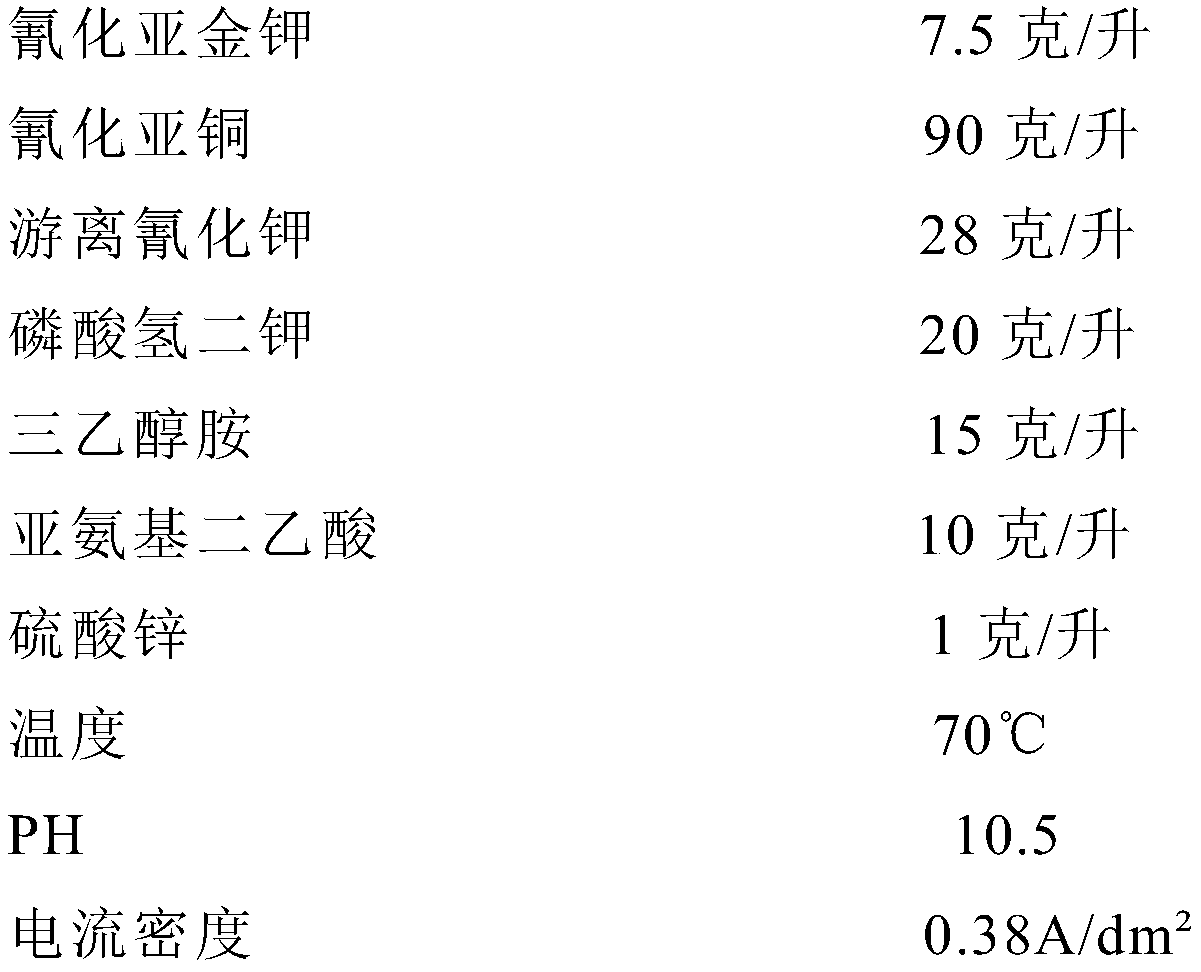

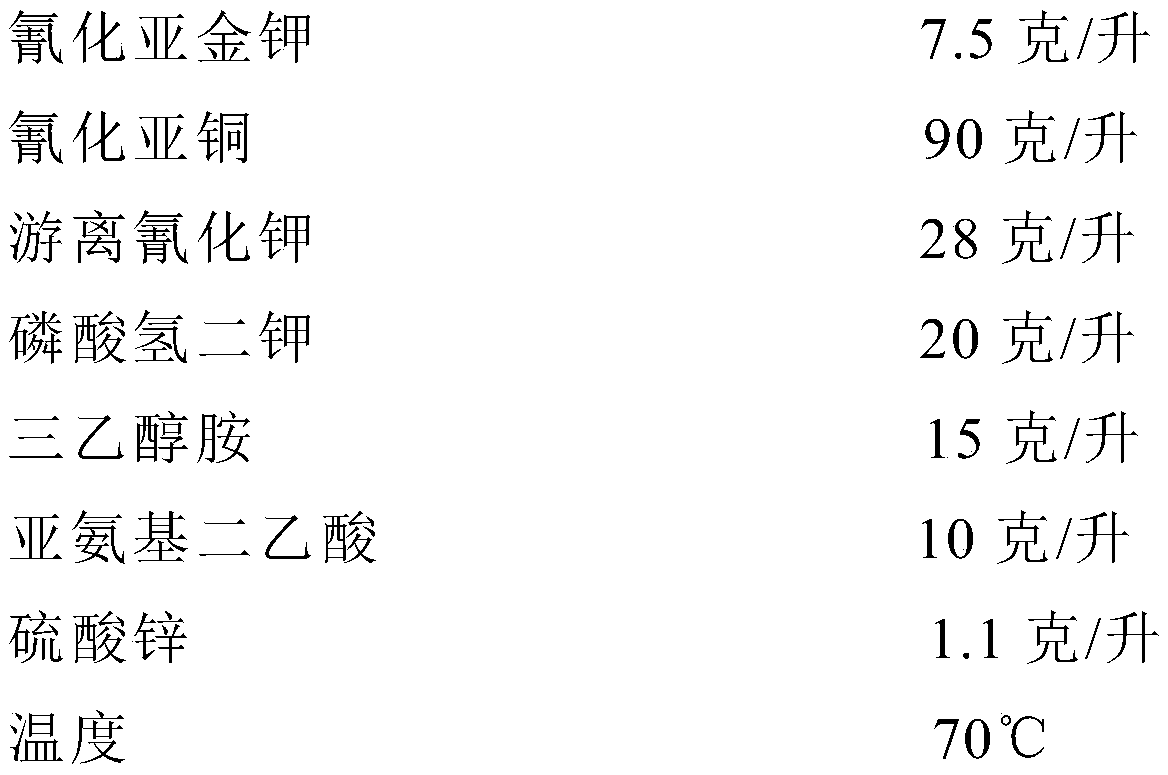

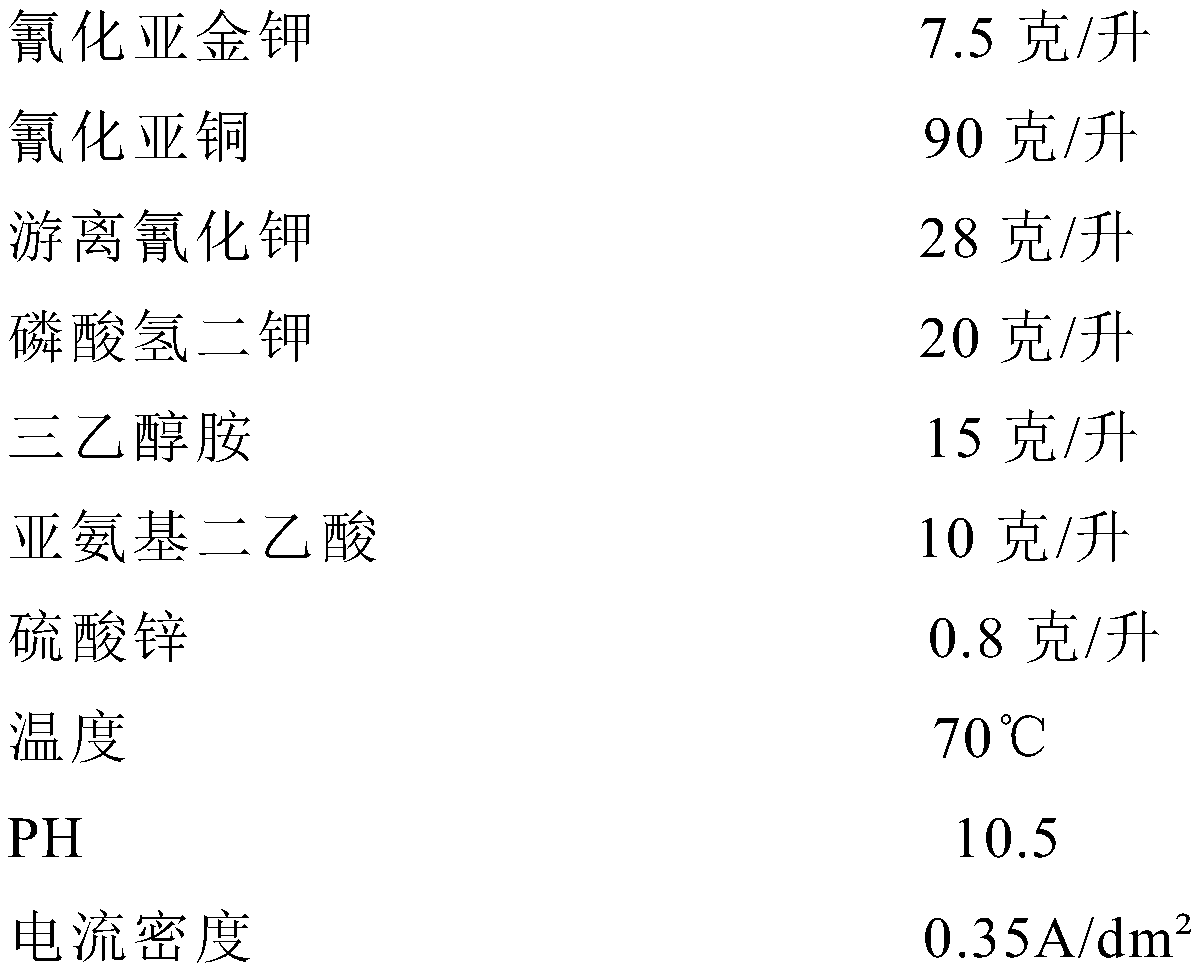

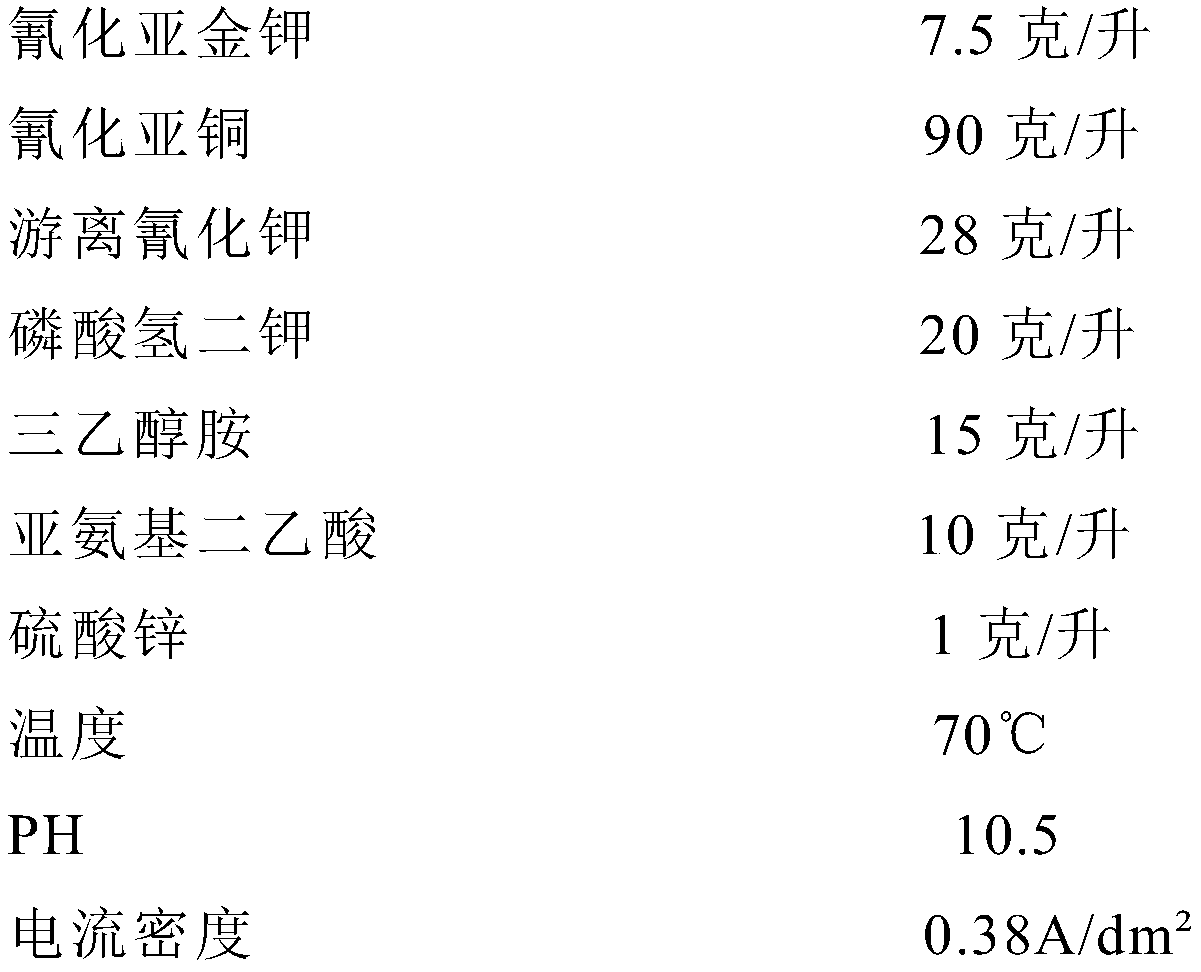

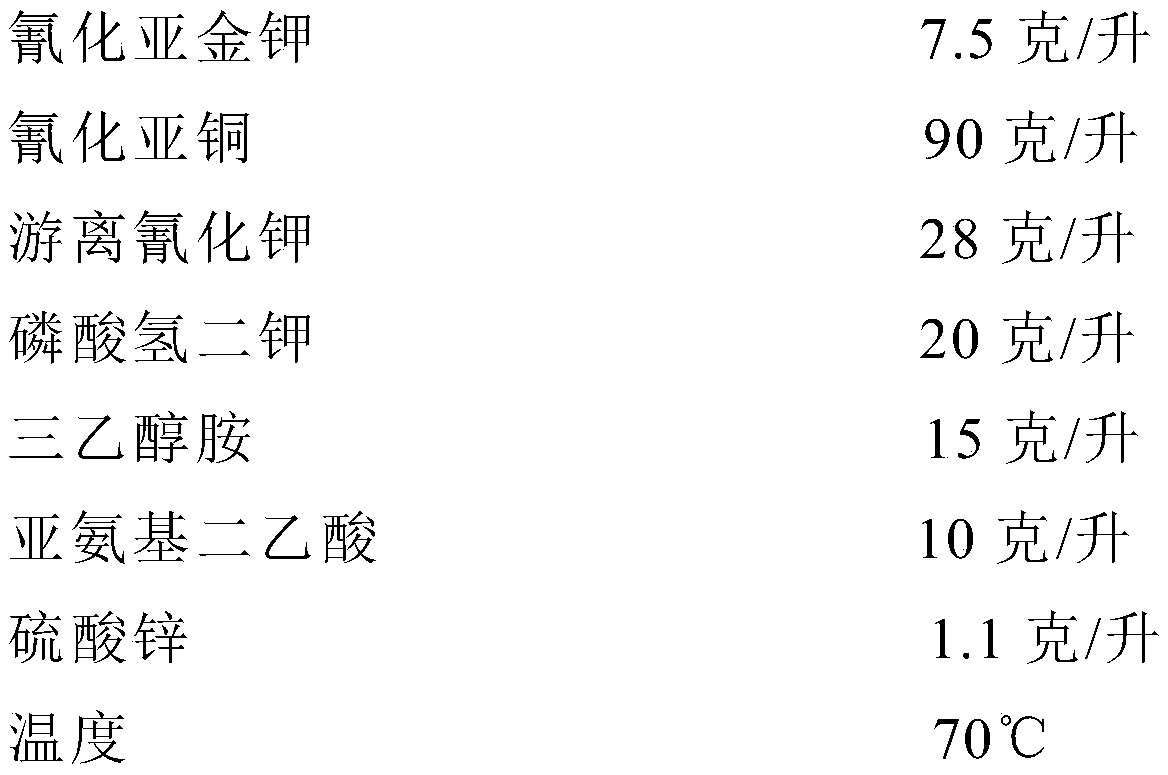

Electroforming liquid for K gold electroforming process

InactiveCN109778245AImprove performanceReduce weightElectroforming processesPotassium cyanidePotassium

The invention relates to electroforming liquid for a K gold electroforming process. The electroforming liquid comprises the following main components with one liter of solution as unit: 4-10 g / l of potassium aurous cyanide, 50-100 g / l of cuprous cyanide, 18-35 g / l of free potassium cyanide, 1-50 g of triethanolamine and 1-30 g / l of iminodiacetic acid as auxiliary complexing agents, 0.2-4 g / l of zinc sulfate as hardening agents, 10-30 g / l of dipotassium phosphate as buffering agents; the electroforming liquid for the K gold electroforming process is prepared through the components, and K gold products are electroformed; K gold is prepared through a gold and copper binary alloy electroforming process; the K gold electroforming liquid with stable performances is used for preparing hollow K gold products with low weights, high hardness, bright rose gold colors and bright and smooth surfaces; and the products have the advantages of low gold consumption, durability, three-dimensional and full shapes and low cost.

Owner:深圳市昊扬电铸技术开发有限公司

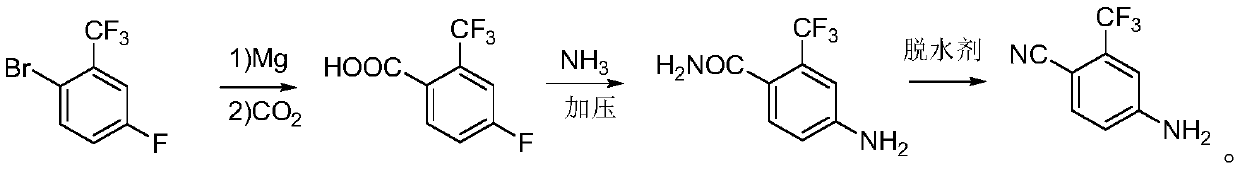

Preparation method of 4-amino-2-trifluoromethyl benzonitrile

The invention relates to the technical field of chemical engineering, in particular to a preparation method of 4-amino-2-trifluoromethyl benzonitrile, which comprises the following steps: after 2-bromo-5-fluorobenzotrifluoride is subjected to a Grignard reaction, feeding carbon dioxide, and hydrolyzing to obtain 4-fluoro-2-trifluoromethyl benzoic acid; adding the 4-fluoro-2-trifluoromethyl benzoicacid into a pressure kettle, feeding liquid ammonia, and reacting under the action of a catalyst to generate 4-amino-2-trifluoromethyl benzamide; heating and dehydrating the 4-amino-2-trifluoromethylbenzamide with a dehydrating agent to generate the 4-amino-2-trifluoromethyl benzonitrile. According to the preparation method, highly toxic cuprous cyanide is not adopted, so that the safety risk ofproduction is reduced, and three wastes do not contain cyanide ions or a large amount of copper ions, are easier to treat and have small harm to the environment.

Owner:常州沃腾化工科技有限公司

Surface treatment method for increasing conductivity of aluminum conductive body for switch cabinet

InactiveCN102605368AImprove performanceReduce consumptionLiquid/solution decomposition chemical coatingSuperimposed coating processCopper platingSodium potassium tartrate tetrahydrate

The invention relates to a surface treatment method for increasing the conductivity of an aluminum conductive body for a switch cabinet. The problems in the conventional surface treatment of the aluminum conductive body can be effectively solved, the conductive property is improved, and the electric transmission effects can be improved. The surface treatment method comprises the following steps of: firstly, preparing zinc soaking liquid, copper pre-plating liquid and copper plating liquid, wherein the zinc soaking liquid is prepared by dissolving sodium hydroxide in water, adding zinc oxide, heating the mixture until the mixture is entirely dissolved, dissolving ferric trichloride and sodium potassium tartrate tetrahydrate in the water, and adding the water and uniformly mixing after mixing; the copper pre-plating liquid is prepared by dissolving sodium cyanide in the water, adding cuprous cyanide, and adding the water to uniformly mix; and the copper plating liquid is prepared by respectively adding water to dissolve and mix copper pyrophosphate, potassium pyrophosphate and disodium hydrogen phosphate, dissolving amine triacetate with a sodium hydroxide solution, and adding the water after the both are mixed; removing oil of the aluminum conductive body, bleaching the aluminum conductive body, soaking the aluminum conductive body into the zinc soaking liquid for zinc soaking twice, placing the aluminum conductive body in the copper pre-plating liquid for copper pre-plating, washing the aluminum conductive body, and then arranging the aluminum conductive body in the copper plating liquid for copper plating so as to achieve a requested thickness. The surface treatment method provided by the invention is simple, is easy to operate and use, is good in effect, and is safe and environment-friendly. Therefore, the properties of a lead wire are improved.

Owner:HENAN XINKAI ELECTRICAL GROUP

Preparation method of 2-nitryl-4-trifluoromethyl benzonitrile

ActiveCN106631886AReduce manufacturing costLow costPreparation by cyanide reactionNon toxicityOrganic synthesis

The invention relates to the technical field of organic synthesis, in particular to a preparation method of 2-nitryl-4-trifluoromethyl benzonitrile. According to the method, 3-nitryl-4-chlorobenzotrifluoride and cyaniding reagents, as raw materials, react with each other under the action of metal bromides and cuprous cyanide to obtain the 2-nitryl-4-trifluoromethyl benzonitrile. The cyaniding reagents are selected from at least one type of ferrous cyanides. The preparation method has the advantages that the metal bromides, which are low in price and easy to get, serve as activating agents, the cuprous cyanide serves as a catalyst, catalysis yield same as nickel bromide can be achieved, and production cost of enterprises can be reduced remarkably; non-toxicity of reaction reagents can be realized through cyanation based on the almost poisonless ferrous cyanides, environment protection requirements can be met, and industrialization can be realized.

Owner:PAPANNA BEIJING TECH

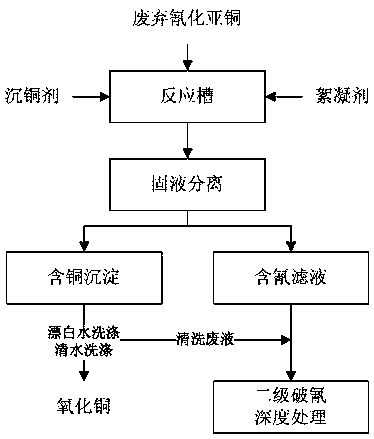

Method for harmless treatment of cuprous cyanide

InactiveCN110092406ADisposal technology is matureHarmlessCopper oxides/halidesHypochloriteFiltration

The invention relates to a method for harmless treatment of cuprous cyanide, particularly to recovery of copper from waste cuprous cyanide poisonous powder and further harmless treatment of waste liquid. According to the method, collected waste cuprous cyanide powder is wetted with a small amount of clear water; a copper precipitating agent solution is added, and complete stirring is performed; asmall amount of a flocculant is added, and filtration is performed to obtain a copper-containing precipitate and a cyanogen-containing filtrate; and the copper-containing precipitate is washed with asodium hypochlorite solution to remove the residual cyanide, air drying is performed to obtain high-purity copper oxide, the washing liquid and the cyanogen-containing filtrate are treated by using atwo-stage cyanogen breaking technology, and the treated material is conveyed to a wastewater plant, and is further subjected to harmless treatment so as to be achieve standard discharge. According tothe present invention, the method has advantages of simple process flow, safe operation, low environmental pollution risk and high copper recovery rate, can fully utilize the existing equipment and technology of the workshop, and further has good environmental protection benefits and economic benefits.

Owner:惠州TCL环境科技有限公司

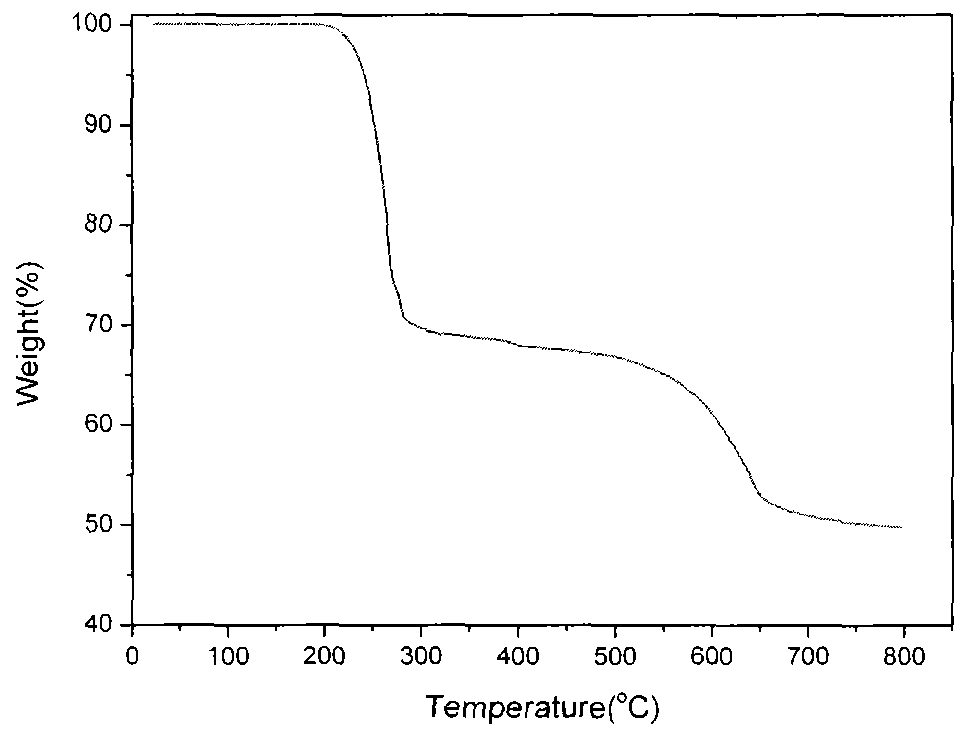

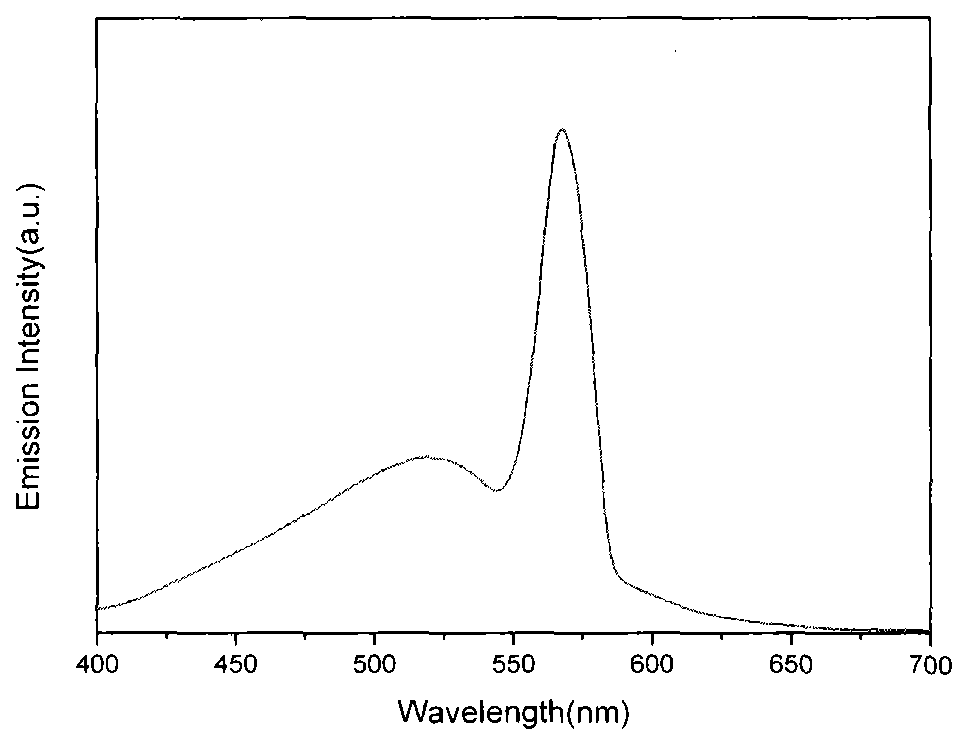

Cuprous complex crystal material and preparation method thereof

InactiveCN103755729ACopper organic compoundsLuminescent compositionsCopper(I) cyanideThermal stability

The invention relates to a cuprous cyanide complex of a 2-aminopyrimidine ligand and a preparation method of the cuprous cyanide complex. The cuprous cyanide complex has a chemical formula [Cu2(CN)2(PymNH2)]n, wherein PymNH2 is 2-aminopyrimidine. The cuprous cyanide complex is a novel three-dimensional framework cuprous complex containing the 2-aminopyrimidine ligand and is simple in synthetic method, easy to crystallize, high in synthetic yield and easily available in raw materials; a crystal material of the complex is high in thermal stability and good in green luminescent properties, and can serve as a green luminescent material to be further applied in the field of material chemistry.

Owner:ANQING NORMAL UNIV

Method for preparing 2-nitro-4-trifluoromethylbenzonitrile

ActiveCN106431979AGood for healthLow toxicityOrganic-compounds/hydrides/coordination-complexes catalystsPreparation by cyanide reactionPotassium cyanideSodium cyanide

The invention discloses a method for preparing 2-nitro-4-trifluoromethylbenzonitrile. The method includes the steps that cuprous cyanide is dissolved in N-methyl-2-pyrrolidone, then a catalyst is added, a thermal reaction is conducted for 8-14 h at 150-160 DEG C after addition, and GC detection is conducted till reaction of 2-nitro-4-(trifluoromethyl)halogenobenzene is finished; the product is cooled to room temperature, the solution is poured into a 40-50% ethyl acetate aqueous solution with the molar weight being 4.0-8.0 times that of a 2-nitro-4-trifluoromethylbenzonitrile crude product under the stirring condition, copper salt is filtered out, a filter cake is washed and extracted by means of ethyl acetate with the molar weight being 2-4 times that of 2-nitro-4-trifluoromethylbenzonitrile, oil layers are mixed and then washed with water, finally the product is dried with anhydrous magnesium sulfate and then subjected to vacuum rectification, and a 2-nitro-4-trifluoromethylbenzonitrile fine product is obtained. Use of virulent cyaniding reagents like sodium cyanide and potassium cyanide is avoided, the catalyst is used, reaction selectivity is improved, the yield is increased, the process is mild, and the yield reaches 90-93%.

Owner:SHANDONG RUNBO BIOTECH CO LTD

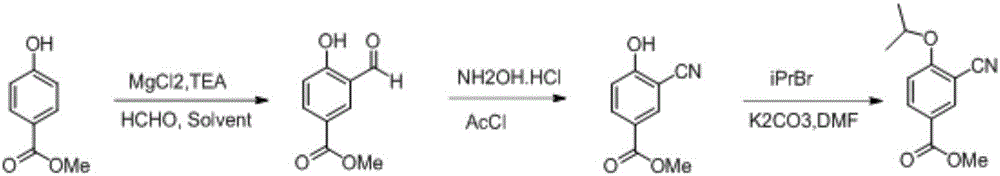

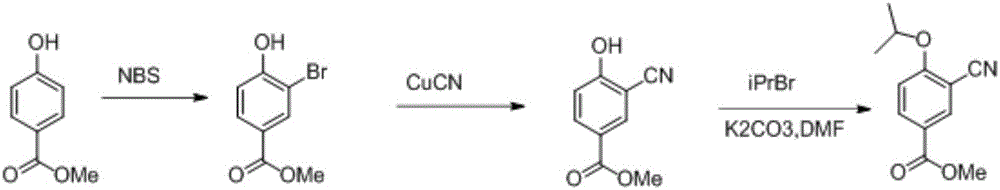

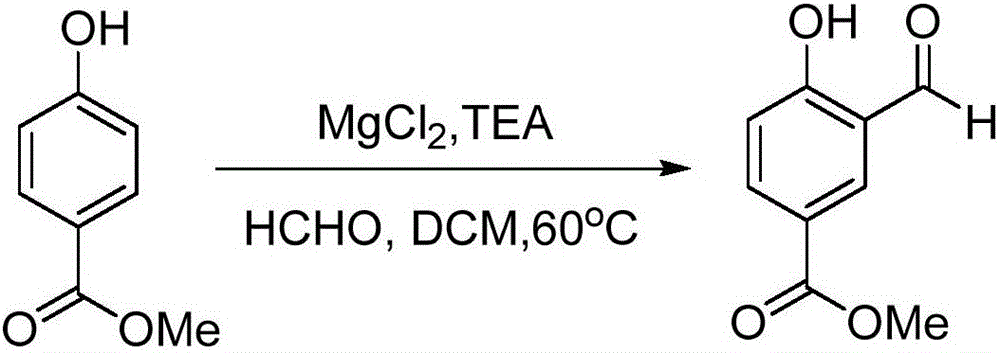

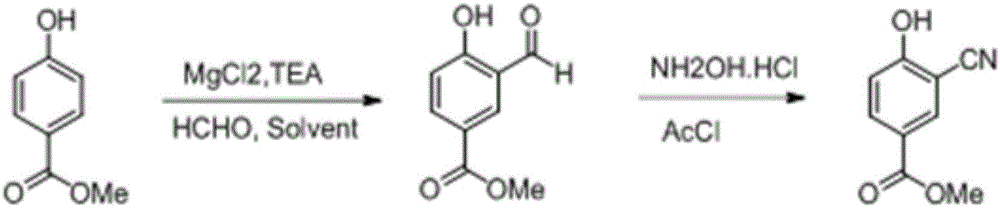

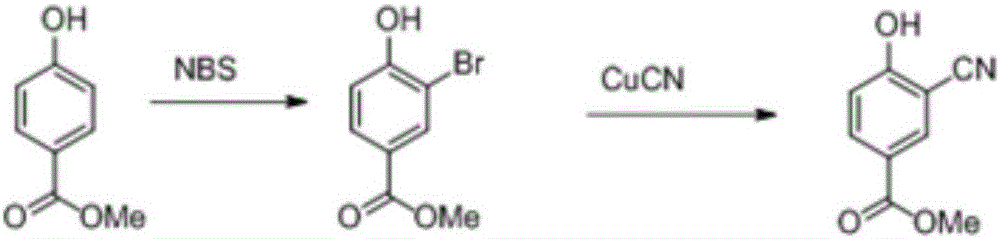

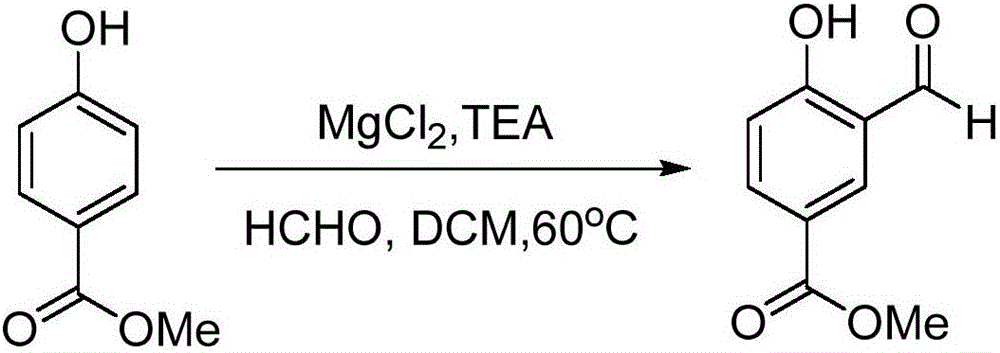

Preparation method of 3-cyano-4-isopropoxy methyl benzoate

InactiveCN106674053ASuitable for industrializationSuitable for mass productionCarboxylic acid nitrile preparationOrganic compound preparationMethyl benzoateCopper(I) cyanide

The invention discloses a preparation method of 3-cyano-4-isopropoxy methyl benzoate. The preparation method comprises the following steps: step I, preparing 3-aldehyde-4-methyl hydroxybenzoate from methyl p-hydroxybenzoate; step II, preparing 3-cyano-4-methyl hydroxybenzoate from the 3-aldehyde-4-methyl hydroxybenzoate; and step III, preparing the 3-cyano-4-isopropoxy methyl benzoate from the 3-cyano-4-methyl hydroxybenzoate. The preparation method of the 3-cyano-4-isopropoxy methyl benzoate provided by the invention has the advantages: (1) the use of cuprous cyanide of highly-toxic cyanide in the previous process is avoided, and the method is more suitable for industrialization; (2) the cyano is prepared from the aldehyde, so that high efficiency and directness can be realized, and mass production can be realized; and (3) all raw materials are cheap and easy to get, and the cost advantage is apparent.

Owner:SUZHOU BLUEHILL BIOPHARMA CO LTD

Preparation method of methyl 3-cyano-4-hydroxybenzoate

InactiveCN106674052ASuitable for industrializationSuitable for mass productionCarboxylic acid nitrile preparationOrganic compound preparationCopper(I) cyanideHydroxybenzoate

The invention discloses a preparation method of methyl 3-cyano-4-hydroxybenzoate. The method comprises the steps of 1, preparing methyl 3-hydroxybenzoate into methyl 3-formyl-4-hydroxybenzoate; 2, preparing the methyl 3-formyl-4-hydroxybenzoate into the methyl 3-cyano-4-hydroxybenzoate. The preparation method of the methyl 3-cyano-4-hydroxybenzoate has the advantages that (1) highly toxic cyanide, i.e., cuprous cyanide used in the previous process is avoided being used in the preparation method, so that the preparation method is more suitable for industrialization; (2) a cyano group is prepared from a formyl group, so that the method is efficient and direct and is suitable for mass production; (3) the raw material is cheap and easy to obtain, so that the method is obvious in cost advantage.

Owner:SUZHOU BLUEHILL BIOPHARMA CO LTD

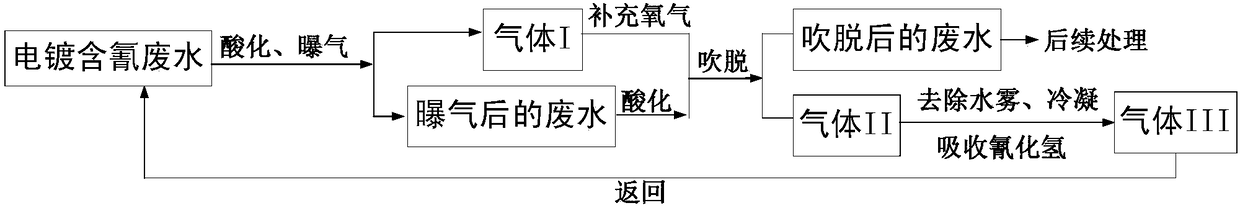

Treatment method of cyanide-containing electroplating waste water

InactiveCN108314218AImprove air stripping effectHigh removal rateWaste water treatment from metallurgical processMultistage water/sewage treatmentCopper(I) cyanideElectroplating

The invention relates to a treatment method of cyanide-containing electroplating waste water. The treatment method comprises following steps: 1, cyanide-containing electroplating waste water is isolated from the external air, and is subjected to acidifying treatment so as to convert carbonates and / or bicarbonates in the cyanide-containing electroplating waste water into carbonic acid and / or carbondioxide, and aeration is carried out so as to obtain a gas I; 2, after aeration in step 1, the cyanide-containing electroplating waste water is subjected to secondary acidifying treatment, and oxygenis mixed with the gas I for air stripping, so that purified water and a gas II are obtained. Compared with conventional acidifying-air stripping, the treatment method is capable of reducing the amount of in-soluble highly toxic cuprous cyanide generated in air stripping process, and improving the air stripping effect of cyanides.

Owner:GUANGDONG XINDAYU ENVIRONMENTAL PROTECTION TECH CO LTD

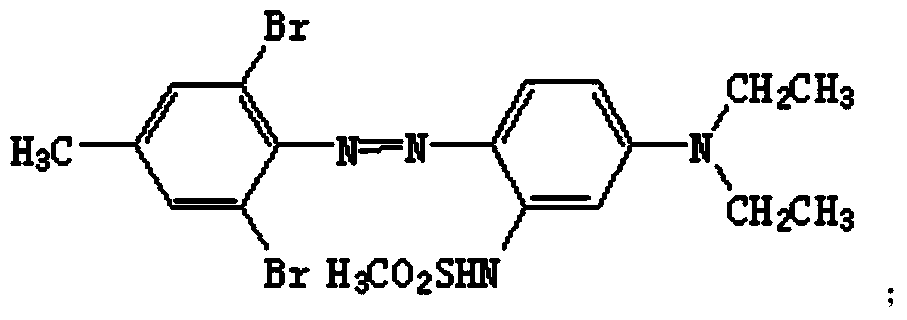

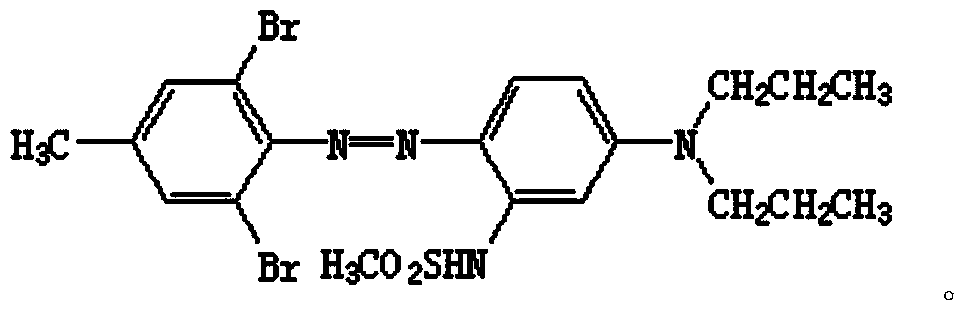

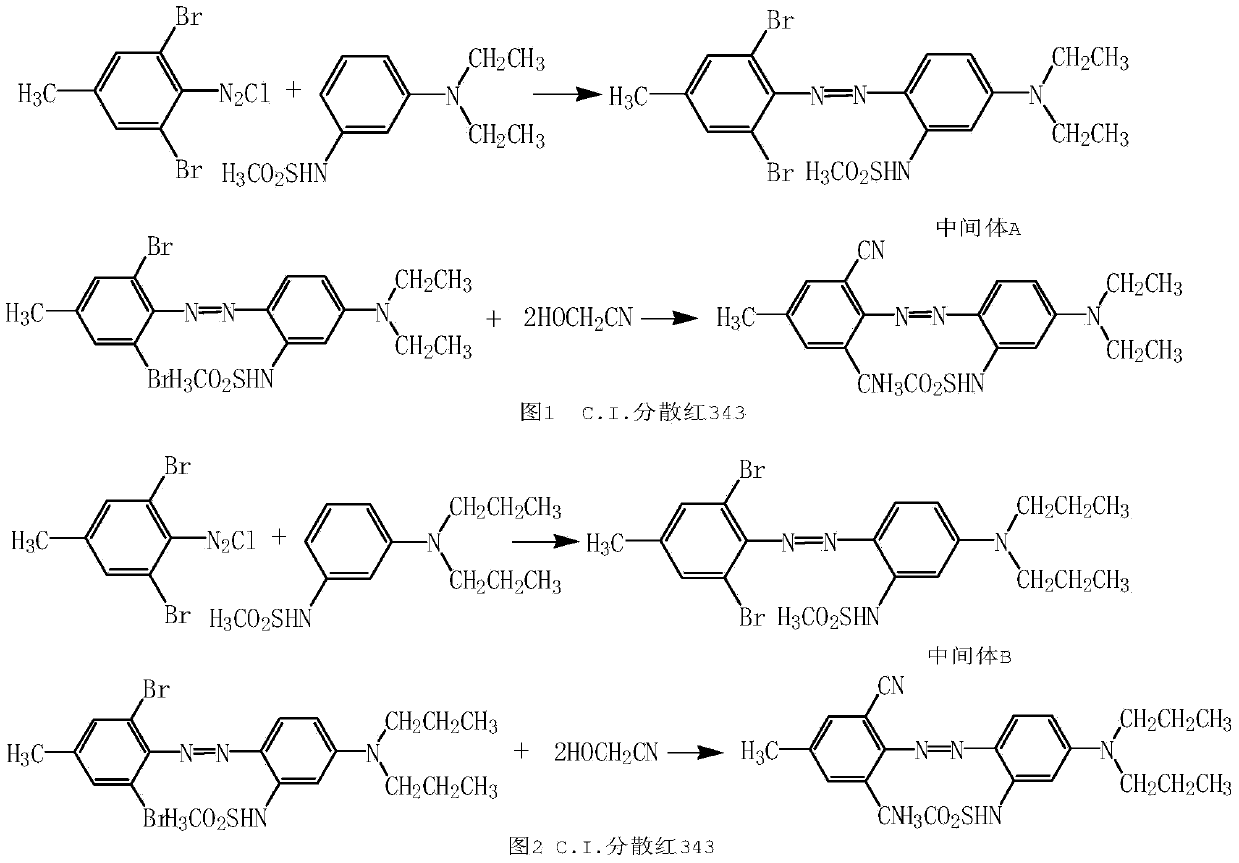

Method for producing disperse red 343

The invention provides a method for producing disperse red 343. The method specifically comprises the following step of cyaniding intermediates A and B by using cyano alcohol in a two-phase system under catalysis of a phase transfer catalyst. According to the method, the step of cyaniding the dried intermediates A and B by cuprous cyanide and zinc cyanide reagents in a DMF (Dimethyl Formamide) solvent in the conventional process is replaced, so that pollution caused by heavy metal ions in a dye is avoided. The cyaniding process is carried out by two phases, and operation of drying the intermediates A and B is omitted, so that the energy consumption and dust pollution are reduced. The method is a brand new pollution-free and environment-friendly synthetic process.

Owner:JIANGSU D I A N CHEM CO LTD

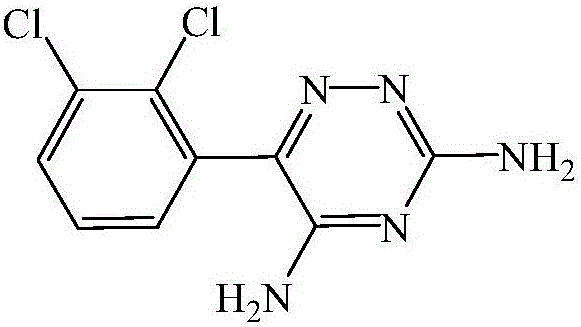

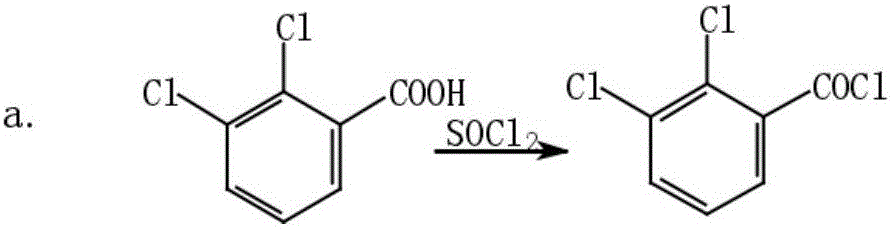

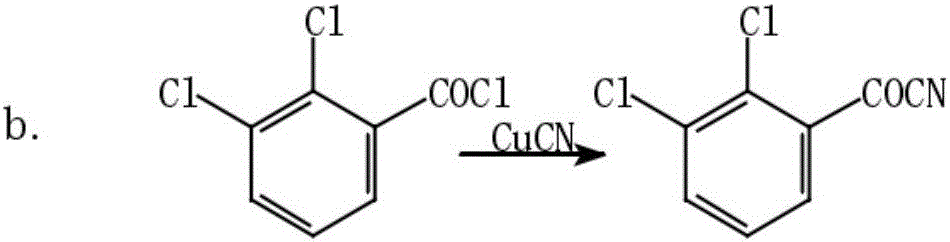

Improved synthesis process for lamotrigine

The invention discloses an improved synthesis process for lamotrigine. The process comprises the following steps: (1) synthesizing 2,3-dichlorobenzoyl cyanide: adding 2,3-dichlorobenzoic acid and thionyl chloride into a reactor, carrying out depressurized evaporating to remove thionyl chloride after a reaction is completed, adding cuprous cyanide into the reactor, and filtering out solids after a reaction is completed, so as to obtain a 2,3-dichlorobenzoyl cyanide solution; (2) preparing a condensate: adding aminoguanidine carbonate and an entrainer into a reactor, dropwise adding concentrated sulfuric acid, distilling off the entrainer and water, carrying out suction filtration, enabling solids to enter a reaction bottle, carrying out depressurized pumping, then, adding the 2,3-dichlorobenzoyl cyanide solution obtained in the step (1) into the reaction bottle, cooling the reaction bottle to room temperature after a reaction is completed, and carrying out suction filtration, so as to obtain the condensate; and (3) preparing cyclics: adding liquid alkali into the condensate obtained in the step (2), and carrying out crystallizing, filtering, washing and baking after a reaction, thereby obtaining the lamotrigine. According to the improved synthesis process for the lamotrigine, the quality and yield of the product, i.e., the lamotrigine can be remarkably increased, and the yield reaches 90% or more.

Owner:ZHEJIANG QICAI ECO TECH CO LTD

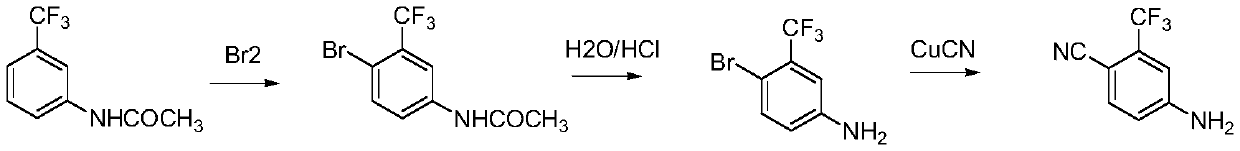

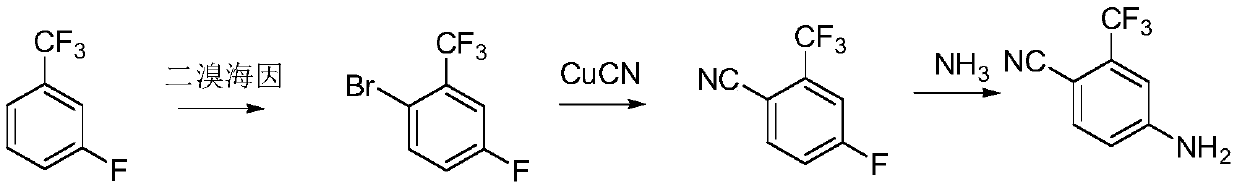

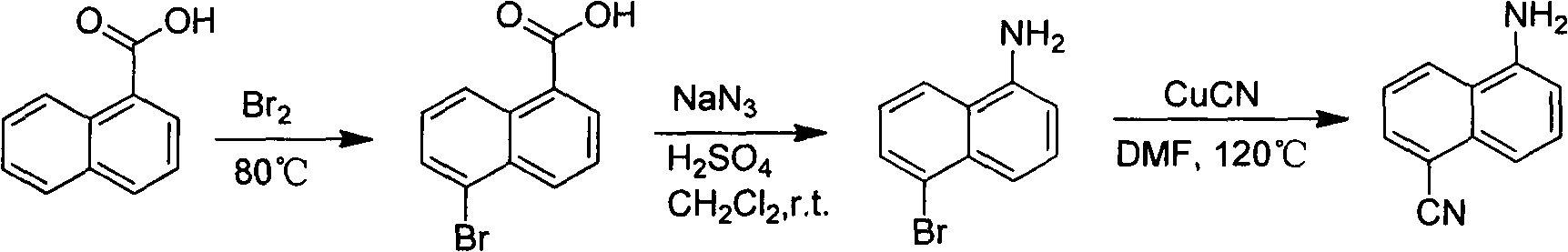

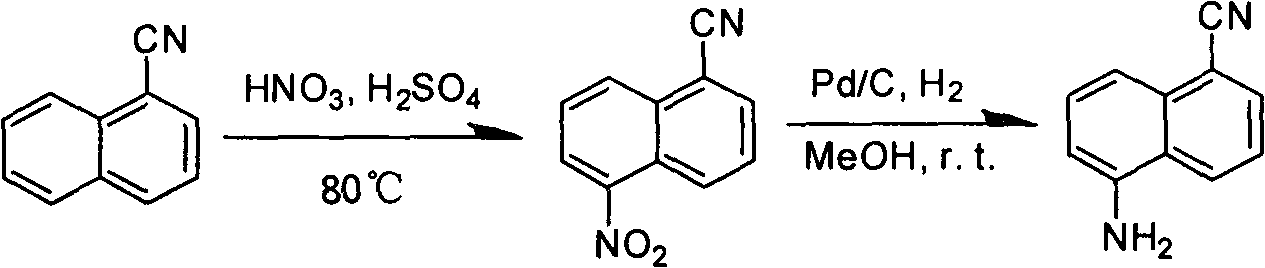

Method for large-scale preparation of 5-amino-1-naphthyl nitrile

InactiveCN102924330ALow priceReduce usageCarboxylic acid nitrile preparationOrganic compound preparationBromineCopper(I) cyanide

The invention relates to a method for large-scale preparation of 5-amino-1-naphthyl nitrile. The method mainly comprises the steps of: by adopting nitronaphthalene as a starting material, carrying out bromination reaction on nitronaphthalene, so as to obtain 5-bromine-1-nitronaphthalene; reacting 5-bromine-1-nitronaphthalene with cuprous cyanide to obtain 5-nitro-1-naphthyl nitrile; and finally reducing 5-nitro-1-naphthyl nitrile to obtain the target product 5-amino-1-naphthyl nitrile. The method has the advantages that: (1) the starting raw material (nitronaphthalene) is cheap; (2) the reaction condition is relatively mild; and (3) the operation is simple and safe (no column chromatography isolation is carried out, and hazardous reagents is avoided using), so that the method is the method easy for large-scale commercial preparation of 5-amino-1-naphthyl nitrile.

Owner:EAST CHINA UNIV OF SCI & TECH

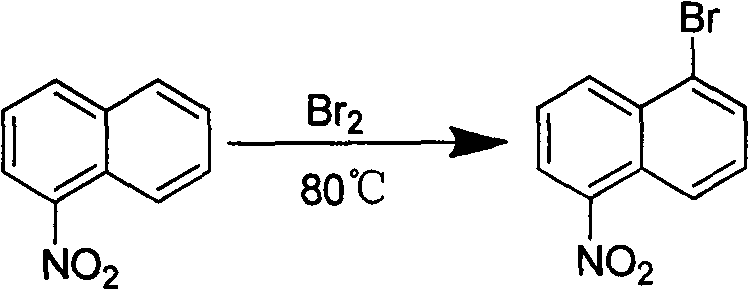

Environmental-friendly preparation method of high-purity cuprous cyanide

The invention discloses an environmental-friendly preparation method of high-purity cuprous cyanide. The method comprises the following preparation steps: (1) adding a copper wire into a reaction tank, adding an aqueous solution of NaCl, introducing chlorine for a period of time, and reacting to produce NaCuCl2; (2) introducing the NaCuCl2 solution into a precipitation tank, adding a NaCN solutionto obtain a CuCN precipitate, filtering, and returning the filtrate to the reaction tank; (3) scrubbing and washing with a sodium chloride solution, and dewatering, thereby obtaining the product. According to the method disclosed by the invention, the copper wire, industrial chlorine as well as industrial sodium chloride and sodium cyanide serve as raw materials, and due to the steps of chloridizing, precipitating, washing, dewatering and the like, the high-purity cuprous cyanide powder can be obtained, and the highest purity can reach 99.92%.

Owner:杭州青化社化工有限公司

Preparation method of 1,4-naphthalic acid

PendingCN112778116AOvercoming Hard-to-Acquire DefectsOrganic compound preparationPreparation by cyanide reactionWhitening AgentsUltraviolet lights

The invention relates to a preparation method of 1,4-naphthalic acid, which is characterized by comprising the steps of performing Friedel-Crafts reaction on 1-naphthalene bromide serving as an initial raw material and acetyl chloride to generate 4-bromo-1-acetyl naphthalene; then carrying out oxidation by using pypocholoride to obtain 4-bromo-1-naphthoic acid; reacting 4-bromine-1-naphthoic acid with cuprous cyanide in a polar aprotic solvent in the presence of potassium iodide and copper sulfate in catalytic doses to generate a 4-cyano naphthoic acid copper salt complex; and carrying out alkaline hydrolysis on the 4-cyano naphthoic acid copper salt complex to obtain the 1,4-naphthalic acid. According to the preparation method of the naphthalene-1,4-dicarboxylic acid, the raw materials are easy to obtain, and the product does not contain color impurities, is high in purity and good in quality, and can be directly used as an intermediate of a dye, an ultraviolet light absorber, a scintillator and an optical whitening agent for further synthesis.

Owner:HUBEI HONGXIN CHEM CO LTD

Preparation method for sawtooth chain-shaped thio-metal cluster functional material with visible light catalytic performance

InactiveCN104826660AImprove photocatalytic performanceGood chemistryWater/sewage treatment by irradiationOrganic-compounds/hydrides/coordination-complexes catalystsFiltrationThio-

The invention discloses a preparation method for a sawtooth chain-shaped thio-metal cluster functional material with visible light catalytic performance. The preparation method comprises the following steps: introducing hydrogen sulfide into an ammonia water solution of tungstic acid or sodium molybdate to react, and preparing ammonium tetrathiotungstate or ammonium tetrathiomolybdate by performing suction filtration and drying; adding the ammonium tetrathiotungstate or ammonium tetrathiomolybdate into a N, N '-dimethyl formamide solution of cuprous cyanide; adding pyridine into the prepared solution, and stirring to prepare a solution containing the sawtooth chain-shaped thio-metal cluster functional material; filtering, adding a precipitator, crystallizing, filtering, washing and drying to obtain the sawtooth chain-shaped thio-metal cluster functional material. The preparation method has the advantage that the sawtooth chain-shaped thio-metal cluster functional material with visible light catalytic performance for effectively degrading organic dye methylene blue is obtained.

Owner:JIANGNAN UNIV

A kind of electroforming liquid used in K gold electroforming process

InactiveCN109778245BImprove performanceReduce weightElectroforming processesPotassium cyanideDipotassium phosphate

The invention relates to electroforming liquid for a K gold electroforming process. The electroforming liquid comprises the following main components with one liter of solution as unit: 4-10 g / l of potassium aurous cyanide, 50-100 g / l of cuprous cyanide, 18-35 g / l of free potassium cyanide, 1-50 g of triethanolamine and 1-30 g / l of iminodiacetic acid as auxiliary complexing agents, 0.2-4 g / l of zinc sulfate as hardening agents, 10-30 g / l of dipotassium phosphate as buffering agents; the electroforming liquid for the K gold electroforming process is prepared through the components, and K gold products are electroformed; K gold is prepared through a gold and copper binary alloy electroforming process; the K gold electroforming liquid with stable performances is used for preparing hollow K gold products with low weights, high hardness, bright rose gold colors and bright and smooth surfaces; and the products have the advantages of low gold consumption, durability, three-dimensional and full shapes and low cost.

Owner:深圳市昊扬电铸技术开发有限公司

Method for preparing cuprous cyanide by using high-concentration cyanogen-containing wastewater

The invention discloses a method for preparing cuprous cyanide by using high-concentration cyanogen-containing wastewater. The method comprises the following preparation steps: preparing Cu<+>; performing CuCN synthesis reaction; adjusting PH; soaking with concentrated sulfuric acid, washing with water, filtering and dehydrating. The Cu<+> is prepared by a reduction method and is added into high-concentration cyanogen-containing wastewater to form cuprous cyanide precipitate, adjusting the PH value of inorganic acid to continuously reduce the cyanogens content of filtrate, and through a seriesof chemical processes, the purity of the cuprous cyanide is continuously improved and the highest purity is 98.92 percent.

Owner:杭州青化社化工有限公司

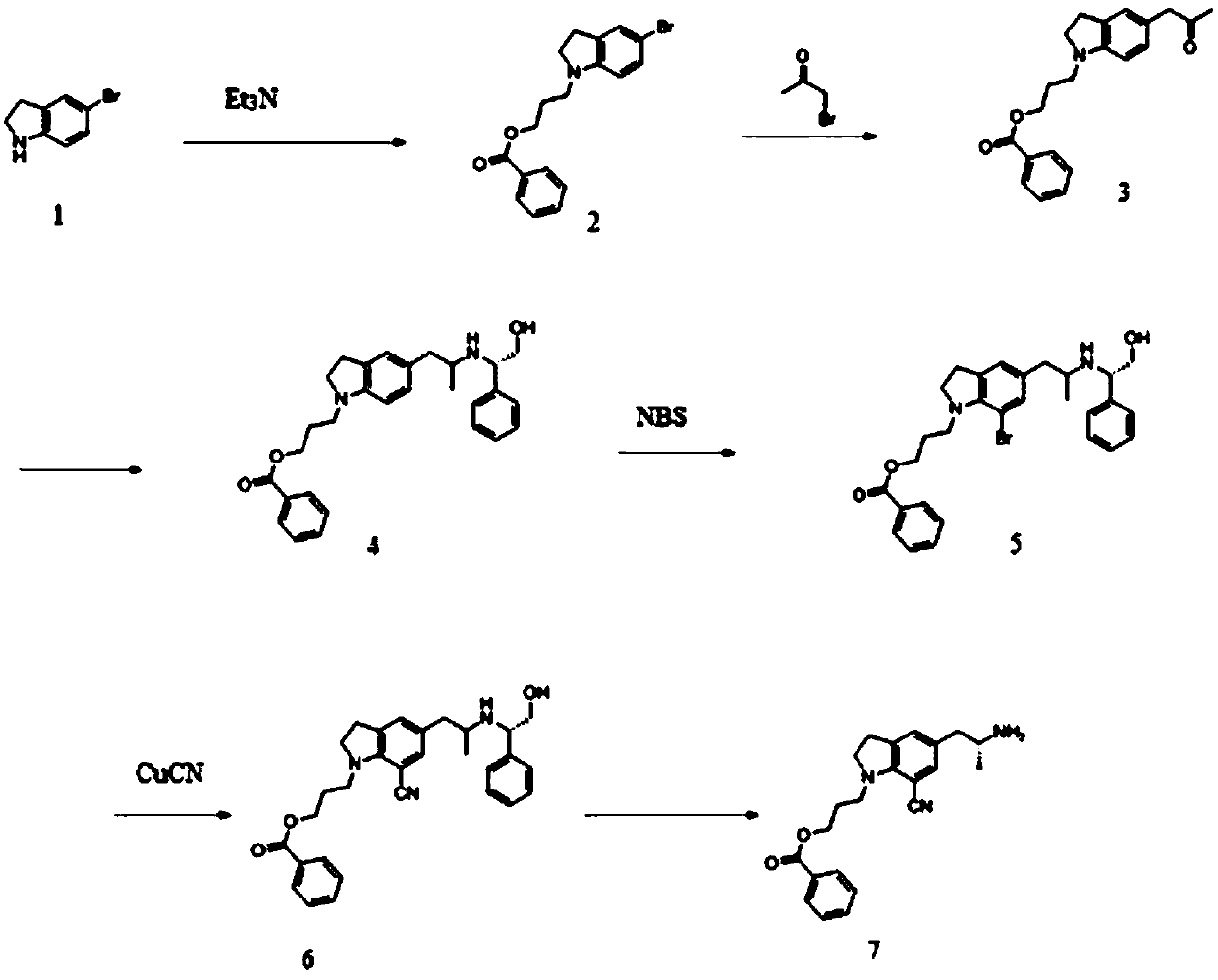

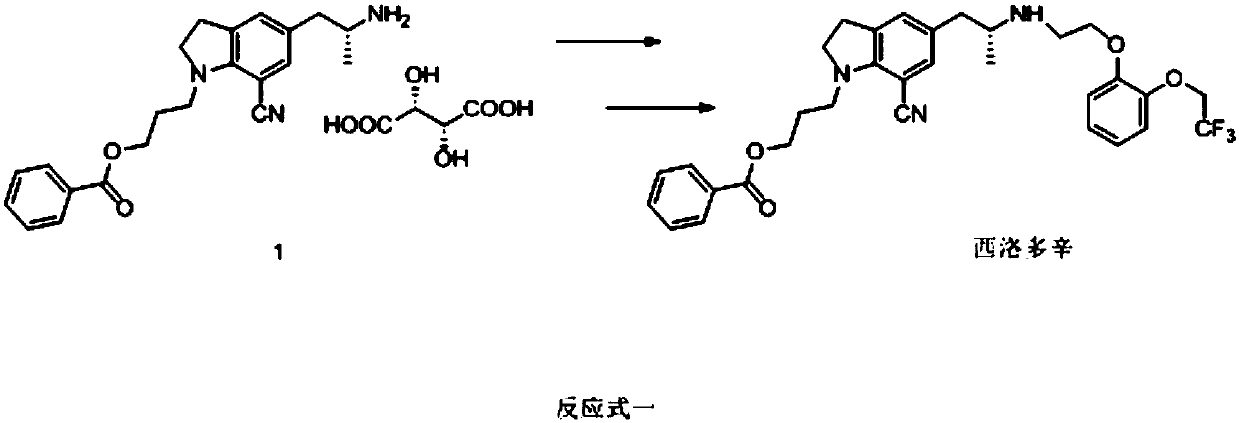

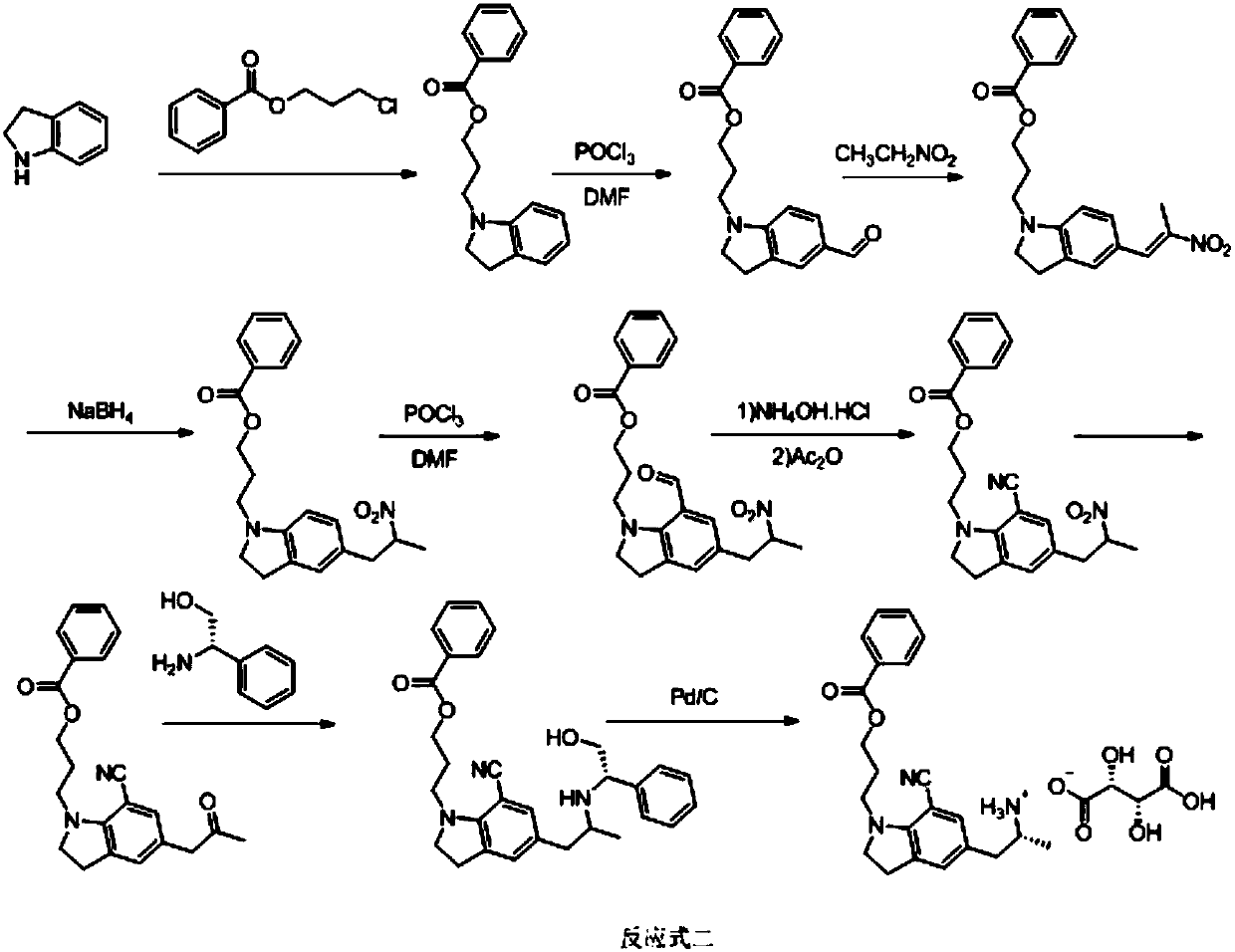

Silodosin intermediate preparing method

The invention discloses a silodosin intermediate preparing method. The silodosin intermediate preparing method comprises the following steps of S1, subjecting 5-bromoindoline solution and triethylamine to alkylation reaction to obtain a material A; S2, subjecting solution of the material A, bromacetone and catalysts to substitution reaction to obtain a material B; S3, subjecting the solution of the material B, catalysts and reducing agent to amination to obtain a material C; S4, subjecting the solution of the material C and N-bromosuccinimide solution to bromination reaction to obtain a material D; S5, subjecting the solution of the material D and cuprous cyanide to cyanation to obtain a material E; S6, subjecting the solution of the material E and catalysts to hydrogenolysis to obtain a tartrate, namely, a silodosin intermediate. The silodosin intermediate preparing method is simple, high in yield, low in energy consumption, green and environmentally friendly; the prepared silodosin intermediate is high in quality and applicable to large-scale industrial production.

Owner:ANHUI QINGYUN PHARMA & CHEM

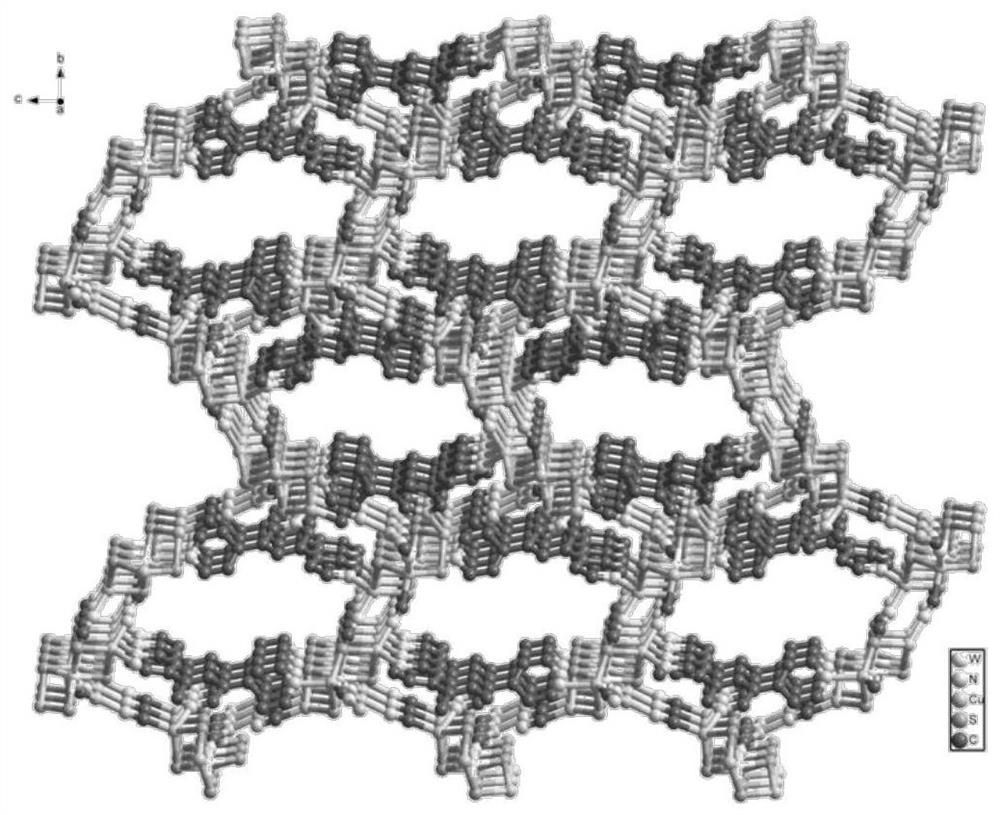

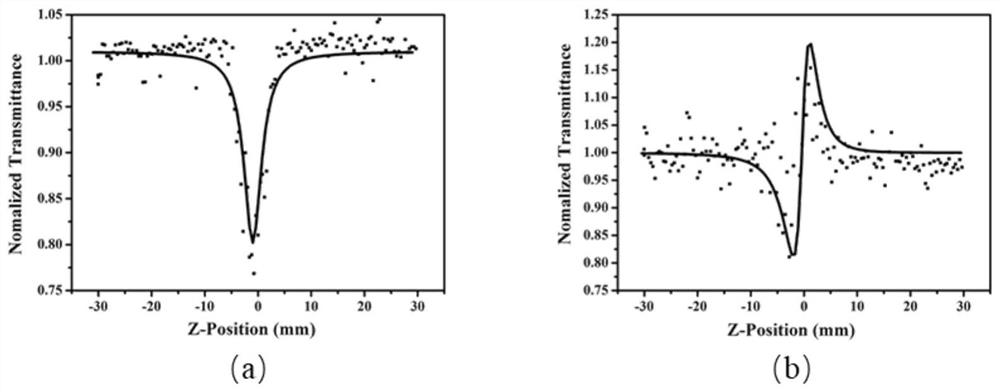

W-S-Cu cluster-based metal organic framework crystal material as well as preparation method and application thereof

The invention discloses a W-S-Cu cluster-based metal organic framework crystal material as well as a preparation method and application thereof. The chemical formula of the metal organic framework crystal material is {[NH4][WS4Cu4 (dpypy)Cu(CN)4].DMF}n, wherein dpypy is 3, 5-bis (4-pyridyl)-pyridine, and the DMF is N, N-dimethyl formamide. The invention also provides a preparation method of the metal organic framework crystal material, ammonium tetrathiotungstate is adopted as a tungsten source and a sulfur source, cuprous cyanide is adopted as a copper source, the tungsten source, the sulfur source, the copper source and 3, 5-bis (4-pyridyl)-pyridine react in an N, N-dimethylformamide solvent, and crystallization is performed to obtain the metal organic framework crystal material. The synthesis method disclosed by the invention is simple, the material yield is high, the purity is high, and the prepared metal organic framework crystal material has strong third-order nonlinear performance.

Owner:JIANGNAN UNIV

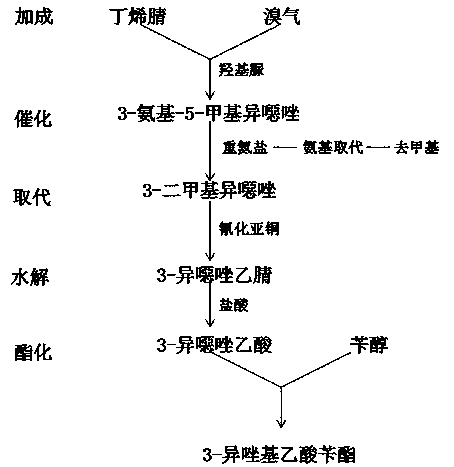

Chemical synthesis method of 3-isoxazolyl benzyl acetate

InactiveCN109251180ARapid responseGuaranteed yieldOrganic chemistryChemical synthesis3-amino-5-methylisoxazole

The invention discloses a chemical synthesis method of 3-isoxazolyl benzyl acetate. The chemical synthesis method comprises the following steps: S1, carrying out addition reaction through butene nitrile and bromine gas and generating 3-amino-5-methylisoxazole in the presence of a hydroxylamine derivative; S2, preparing 3-amino-5-methylisoxazole into diazonium salt under low temperature under the action of catalysis, carrying out substitution reaction on the diazonium salt in a hydrochloric acid environment, substituting amino and preparing 3,5-dimethylisooxazole, carrying out demethylation andpreparing 3-chloromethylisoxazole; and S3, adding 3-chloromethylisoxazole and cuprous cyanide into an organic solvent which is dimethyl sulfoxide, reacting and preparing 3-isooxazole acetonitrile. According to the chemical synthesis method of 3-isoxazolyl benzyl acetate, the raw materials are products obtained by directly cracking petroleum; production is carried out by five steps of addition, catalysis, substitution, hydrolysis and esterification; the reaction is rapid; when 3-chloromethylisoxazole as an intermediate is prepared, the yield reaches up to 75%; the production yield is ensured.

Owner:盐城锦明药业有限公司 +1

Method for synthesizing N-aryl-phenoxazine compounds

ActiveCN103819423BEfficiently control the sequence of cascade reactionsControlling the order of cascade reactionsOrganic chemistryChemical synthesisCarboxylic salt

The invention discloses a method for synthesizing N-aryl-phenoxazine compounds, and belongs to the chemical synthesis filed. The method comprises the following steps: taking a compound represented by the formula I, which is shown in the description, as the raw materials; mixing the compound with a solvent, a catalyst, and an alkali reagent, adding an arylation agent, and carrying out reactions at a temperature of 50 to 250 DEG C so as to obtain the target product; wherein the solvent is amides, benzenes, or nitriles; the catalyst is copper halide, cuprous halide, alkyl copper carboxylate, alkyl copper carboxylate hydrate, aryl copper carboxylate, cuprous oxide, or cuprous cyanide; and the arylation agent is iodobenzenes represented by formula II, which is shown in the description, mono-substituted iodopyridine, or 3-iodothiophene. The method has the advantages of simple reaction steps and high yield of target product.

Owner:JIANGSU AOLUNDA HIGH TECH IND

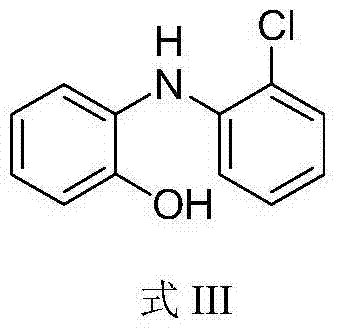

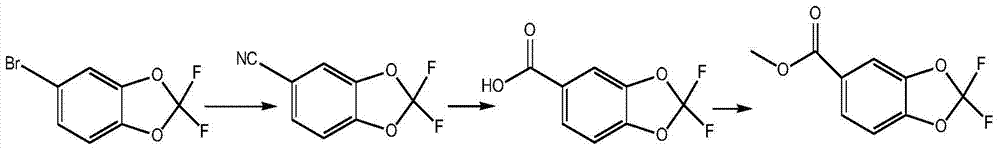

A kind of preparation method of 2,2-difluoropiperic acid methyl ester

ActiveCN105153106BSimple processReaction is easy to controlOrganic chemistryCarboxylic saltCopper(I) cyanide

The invention discloses a preparation method of methyl 2,2-difluorobenzo[d][1,3]dioxole-5-carboxylate. The method comprises the steps of performing cyanation reaction to 5-bromo-2,2-difluoro-1,3-benzodioxole and cuprous cyanide, then performing hydrolysis to form acid, and then performing esterification to obtain 2,2-difluorobenzo[d][1,3]dioxole-5-carboxylate. In the preparation method disclosed by the invention, by using 5-bromo-2,2-difluoro-1,3-benzodioxole as a start raw material, performing cyanation by using low-toxicity cuprous cyanide, then performing hydrolysis to form acid and performing methanol reaction esterification to obtain the product, the process flow of the method is simple and the reaction process is easy to control. In the reaction process, the purification of the intermediate product produced in each step does not need a complex purification process, the purification process is simple, the purification yield is high, the entire process flow is simple and high-efficiency, the product yield is high, the cost of the entire flow is low and the preparation method is very suitable for large-scale industrial production.

Owner:辽宁鸿鹄医药化学技术有限公司

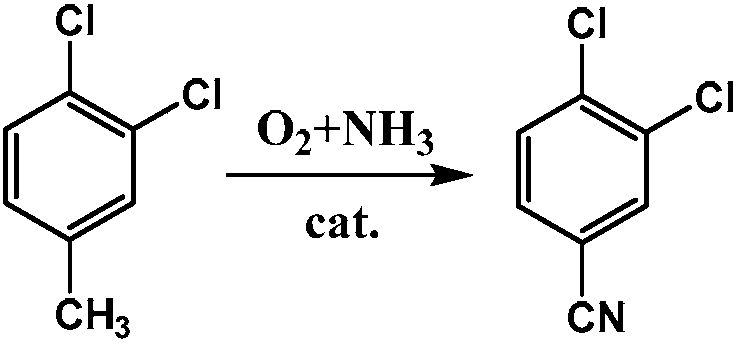

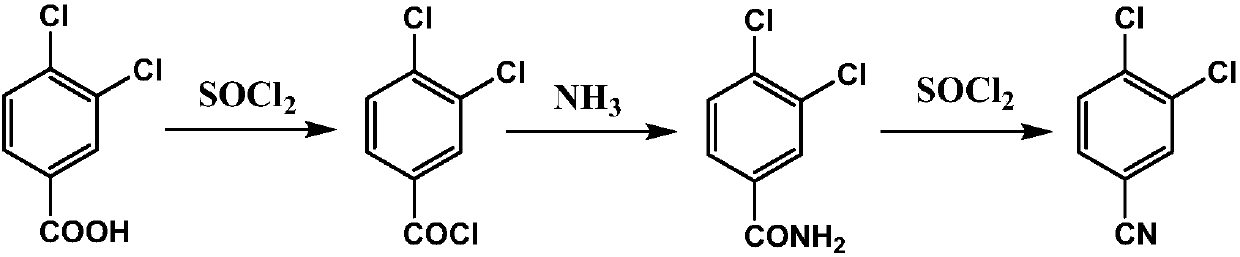

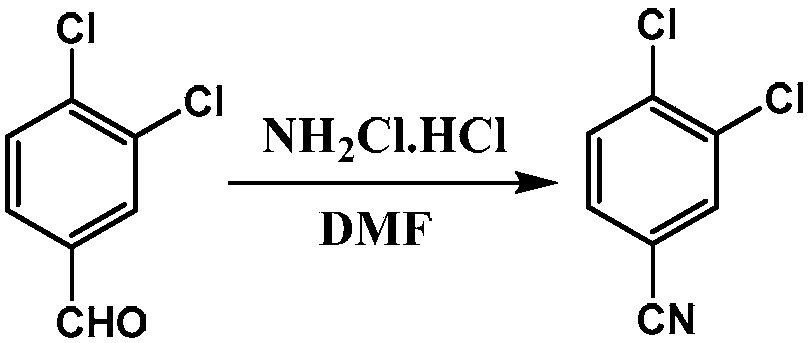

Synthesis method of 3,4-dichlorobenzonitrile

ActiveCN107915659ALow costSuitable for industrial productionPreparation by cyanide reactionHalogenated hydrocarbon preparation2-dichlorobenzeneSynthesis methods

The invention discloses a synthesis method of 3,4-dichlorobenzonitrile. The synthesis method comprises the following steps of (1) adopting 1,2-dichlorobenzene as a raw material, adding a catalyst A, rising the temperature, then dropwise adding bromine, carrying out heat insulating reaction after the dropwise adding is finished, and carrying out aftertreatment to obtain 3,4-dichlorobromobenzene; (2) after mixing cuprous cyanide, a catalyst B and a solvent, dropwise adding 3,4-dichlorobromobenzene diluent after rising the temperature, carrying out heat insulating reaction after the dropwise adding is finished, and carrying out aftertreatment to obtain the 3,4-dichlorobenzonitrile. The synthesis method disclosed by the invention has the beneficial effects that the 1,2-dichlorobenzene is adopted as the raw material, and after two-step reaction of bromination and cyaniding, the 3,4-dichlorobenzonitrile is obtained, the molar yield can reach 85% or above and the purity is greater than or equal to 98%. The synthesis method disclosed by the invention is low in raw-material cost so as to be suitable for industrial production.

Owner:ZHEJIANG LINJIANG CHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Preparation method of crystal material [WS4Cu4(CN)2(TPP) (2, 3, 5, 6-4-tetra-pyridyl pyrazine)] with high detection sensitivity for TNP (2, 4, 6-trinitrophenol) Preparation method of crystal material [WS4Cu4(CN)2(TPP) (2, 3, 5, 6-4-tetra-pyridyl pyrazine)] with high detection sensitivity for TNP (2, 4, 6-trinitrophenol)](https://images-eureka.patsnap.com/patent_img/5bfa2bee-3b66-41b4-b2ab-40f3507c2f69/HDA0001480513010000011.png)

![Preparation method of crystal material [WS4Cu4(CN)2(TPP) (2, 3, 5, 6-4-tetra-pyridyl pyrazine)] with high detection sensitivity for TNP (2, 4, 6-trinitrophenol) Preparation method of crystal material [WS4Cu4(CN)2(TPP) (2, 3, 5, 6-4-tetra-pyridyl pyrazine)] with high detection sensitivity for TNP (2, 4, 6-trinitrophenol)](https://images-eureka.patsnap.com/patent_img/5bfa2bee-3b66-41b4-b2ab-40f3507c2f69/HDA0001480513010000012.png)

![Preparation method of crystal material [WS4Cu4(CN)2(TPP) (2, 3, 5, 6-4-tetra-pyridyl pyrazine)] with high detection sensitivity for TNP (2, 4, 6-trinitrophenol) Preparation method of crystal material [WS4Cu4(CN)2(TPP) (2, 3, 5, 6-4-tetra-pyridyl pyrazine)] with high detection sensitivity for TNP (2, 4, 6-trinitrophenol)](https://images-eureka.patsnap.com/patent_img/5bfa2bee-3b66-41b4-b2ab-40f3507c2f69/HDA0001480513010000013.png)

![Preparation method of crystal material {[NH4][TbCu(ina)4(CN)].2DMF}n with function of selectively adsorbing organic dye Preparation method of crystal material {[NH4][TbCu(ina)4(CN)].2DMF}n with function of selectively adsorbing organic dye](https://images-eureka.patsnap.com/patent_img/500b3ef7-23ce-4503-b8cb-b8e0d79ca932/HDA0001010340360000011.PNG)

![Preparation method of crystal material {[NH4][TbCu(ina)4(CN)].2DMF}n with function of selectively adsorbing organic dye Preparation method of crystal material {[NH4][TbCu(ina)4(CN)].2DMF}n with function of selectively adsorbing organic dye](https://images-eureka.patsnap.com/patent_img/500b3ef7-23ce-4503-b8cb-b8e0d79ca932/HDA0001010340360000012.PNG)