Environmental-friendly preparation method of high-purity cuprous cyanide

A cuprous cyanide, environment-friendly technology, applied in the direction of metal cyanide, etc., can solve the problems of three wastes pollution, failure to give high-purity cuprous cyanide preparation steps, high production cost, etc., and achieve the effect of full absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

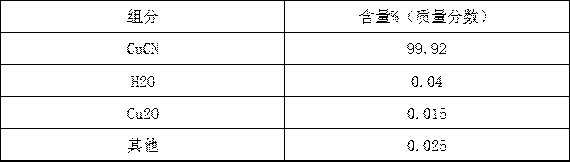

Embodiment 1

[0022] An environment-friendly preparation method of high-purity cuprous cyanide, the preparation steps are as follows:

[0023] (1) Put the copper wire into the primary reaction tank, add 25% (mass fraction) NaCl aqueous solution, and pass chlorine gas for 15 minutes, the temperature of the reaction tank is 25°C, the reaction generates NaCuCl2, and the excess chlorine gas is passed into the secondary reaction tank ;

[0024] (2) Introduce the NaCuCl2 solution into the precipitation tank, add the NaCN solution, and react for 28 minutes to obtain CuCN precipitation. After filtering, the filtrate is returned to the reaction tank;

[0025] (3) After washing with sodium chloride solution, washing with water, concentrating, crystallizing, centrifuging and drying, the product is obtained, and the purity of the product is 99.92%.

[0026] As a preference, a rock wool insulation layer is arranged outside the reaction tank.

[0027] Preferably, the volume of the copper wires accounts...

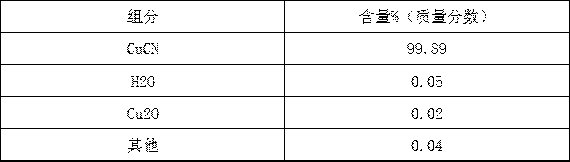

Embodiment 2

[0041] An environment-friendly preparation method of high-purity cuprous cyanide, the preparation steps are as follows:

[0042] (1) Put the copper wire into the primary reaction tank, add 20% (mass fraction) NaCl aqueous solution, and pass chlorine gas for 20 minutes, the temperature of the reaction tank is 30°C, the reaction generates NaCuCl2, and the excess chlorine gas is passed into the secondary reaction tank and a three-stage reaction tank;

[0043] (2) Introduce the NaCuCl2 solution into the precipitation tank, add the NaCN solution, and react for 30 minutes to obtain the CuCN precipitate. After filtering, the filtrate is returned to the reaction tank;

[0044] (3) After washing with sodium chloride solution, washing with water, concentrating, crystallizing, centrifuging and drying, the product is obtained, and the purity of the product is 99.89%.

[0045] As a preference, a rock wool insulation layer is arranged outside the reaction tank.

[0046] Preferably, the vo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com