Method for harmless treatment of cuprous cyanide

A harmless treatment, cuprous cyanide technology, applied in the direction of copper oxide/copper hydroxide, etc., can solve the problems of high cost investment and inapplicability, and achieve the effect of low requirements for production equipment, simple process and easy industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

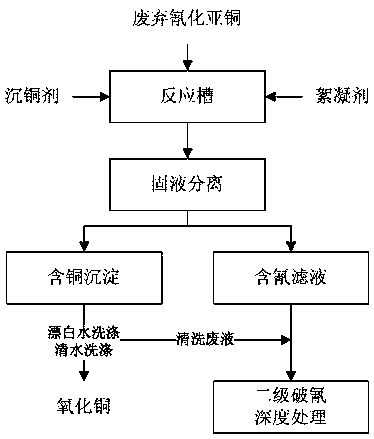

Image

Examples

Embodiment Construction

[0016] The process method of the present invention will be further described in detail below in conjunction with specific embodiments of the present invention.

[0017] (1) Add 85kg of sodium sulfide solid (purity 52%) to the reaction tank, add water to make 10% sodium sulfide solution;

[0018] (2) Pour 100kg of cuprous cyanide powder (among them, the mass fraction of cuprous cyanide is 73.6%), stir slowly, fully react, and the reaction time is 40-60min;

[0019] (3) Add a small amount of 0.3% PAM solution to the reaction tank for coagulation and precipitation;

[0020] (4) After standing for solid-liquid separation, filter directly with filter cloth, and collect copper-containing precipitate and filtrate respectively;

[0021] (5) Wash the precipitate twice with a small amount of bleaching water, then wash it with clean water to neutrality, and dry it to obtain high-purity copper oxide powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com