Methanol fuel for ignition type engine

A methanol fuel and engine technology, which is applied to the field of methanol fuel for ignition engines, can solve the problems of rubber swelling, metal corrosiveness, large amount of additives, etc., and achieves the effects of simple composition, energy saving, and reduction of the amount of additives.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

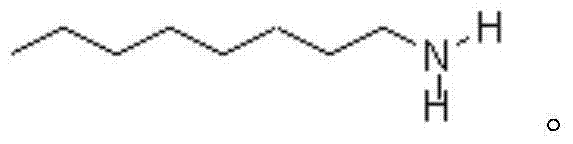

[0032] Take 200ml of refined methanol with a content greater than 99.9%, 795ml of gasoline component oil, and 5ml of n-octylamine in a 150ml beaker, stir and mix evenly. The product obtained in this embodiment is tested, and the indicators are as shown in Table 1.

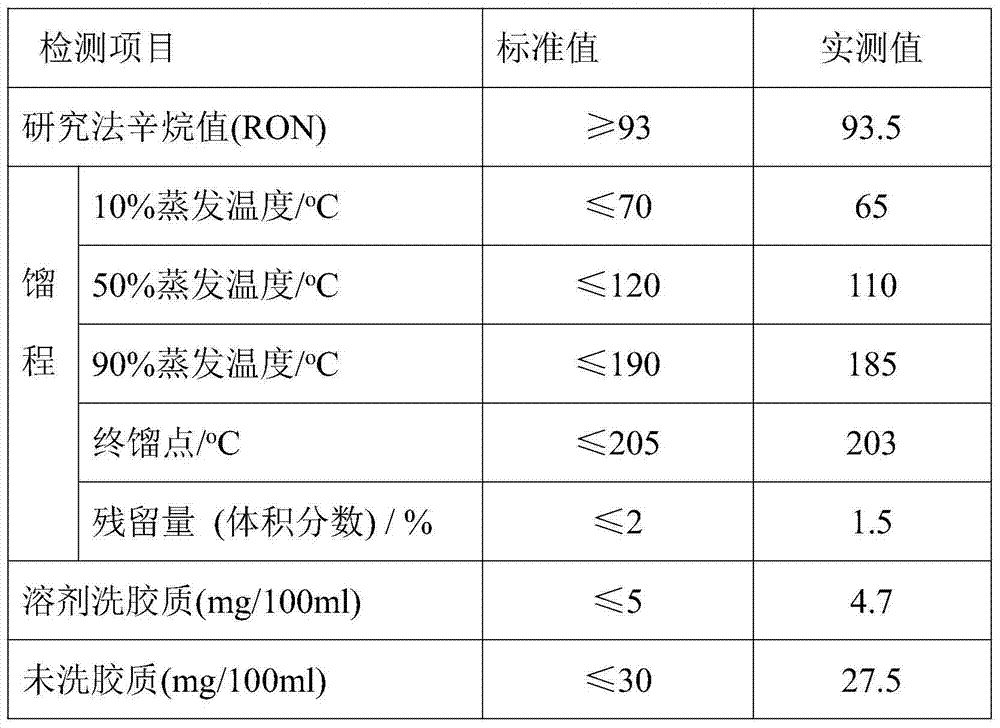

[0033] Table 1 Example 1 methanol fuel detection results

[0034]

[0035]

Embodiment 2

[0037] Use a metering pump to extract 400L of refined methanol with a content greater than 99.9%, 597L of gasoline component oil, and 3L of industrial grade n-octylamine into a mixing tank, and use a circulating pump to circulate and mix through a pipeline mixer, stir for about 20 minutes, and mix well. The resulting product was tested, and the results are shown in Table 2.

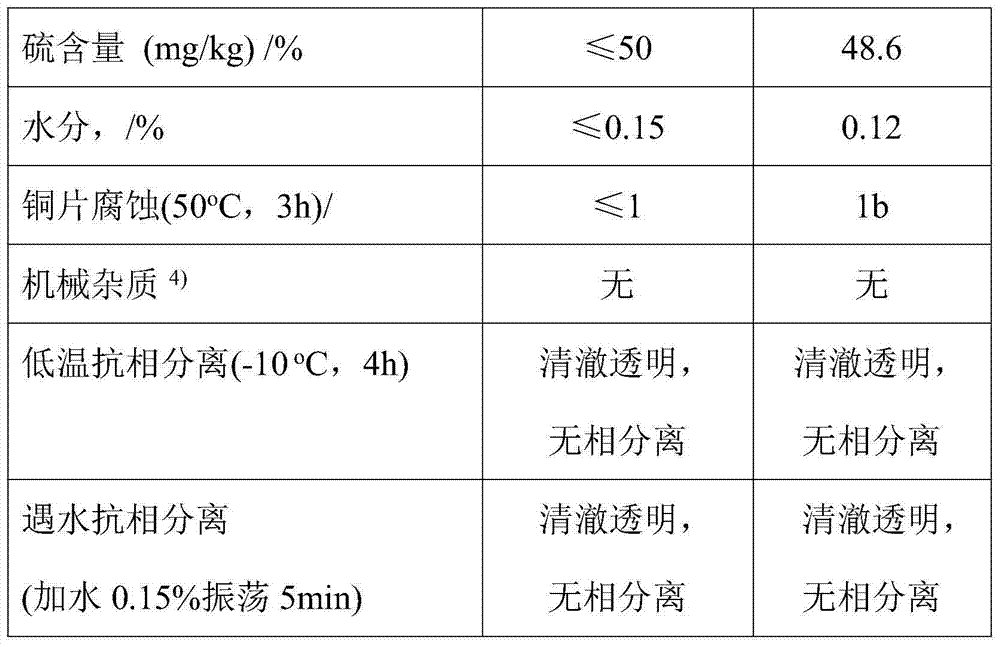

[0038] Table 2 Example 2 methanol fuel detection results

[0039]

[0040]

Embodiment 3

[0042] Use a metering pump to extract 6450L of refined methanol with a content greater than 99.9%, 3500L of 93# gasoline, and 50L of industrial grade n-octylamine into the mixing tank, and use a circulation pump to circulate and mix through the pipeline mixer, stir for about 60 minutes, and mix well. The resulting product was tested, and the results are shown in Table 3.

[0043] Table 3 Example 3 methanol fuel detection results

[0044]

[0045]

PUM

| Property | Measurement | Unit |

|---|---|---|

| percent by volume | aaaaa | aaaaa |

| percent by volume | aaaaa | aaaaa |

| percent by volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com