Microbial cell conversion method for producing 2-keto-D-gluconic acid

A microbial cell and gluconic acid technology, which is applied in the field of microbial cell transformation to produce 2-keto-D-gluconic acid, can solve the problems of large waste residue treatment, large heat release, and affecting enzyme activity, and achieve simple separation and purification. The effect of saving production cost and high conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

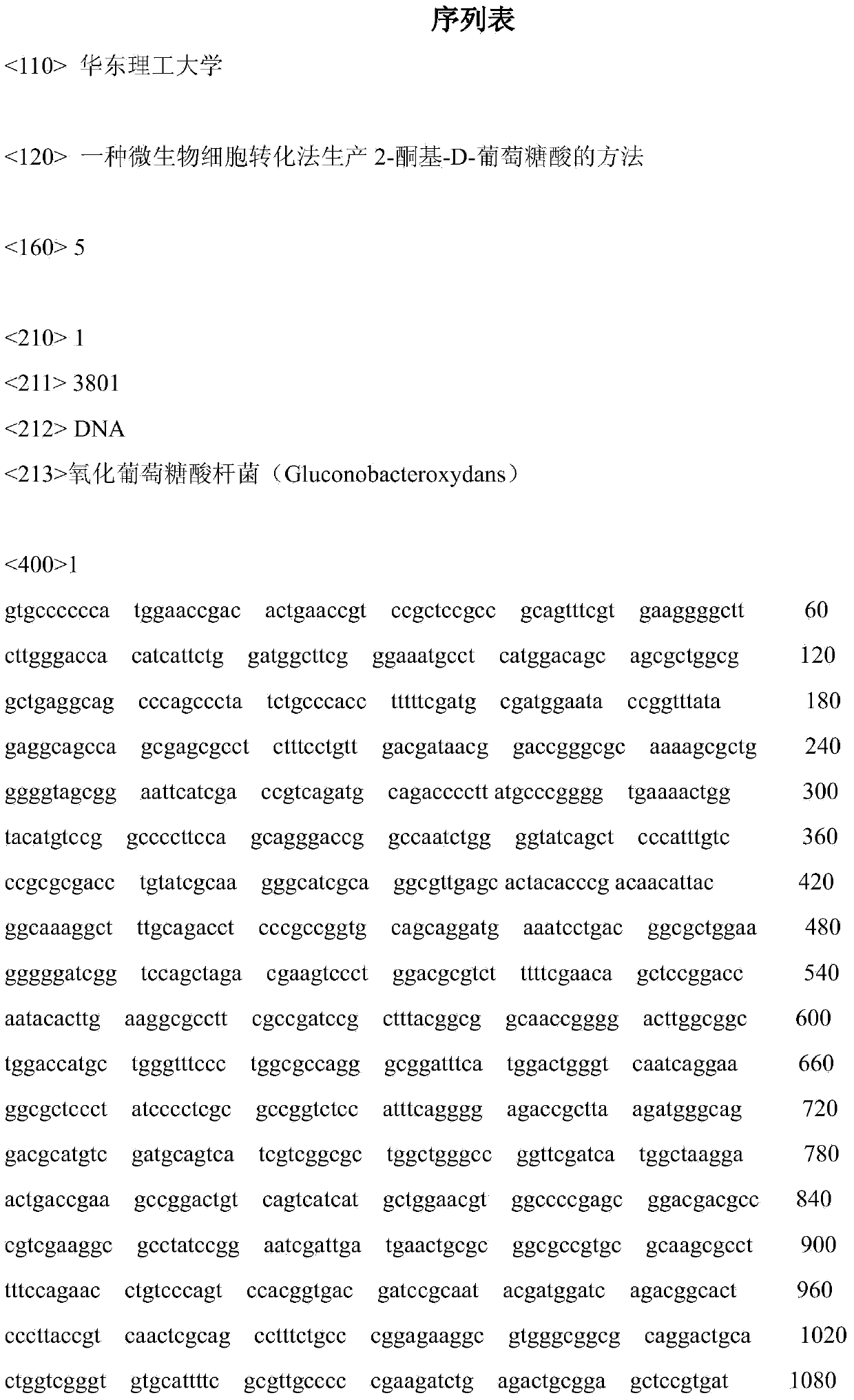

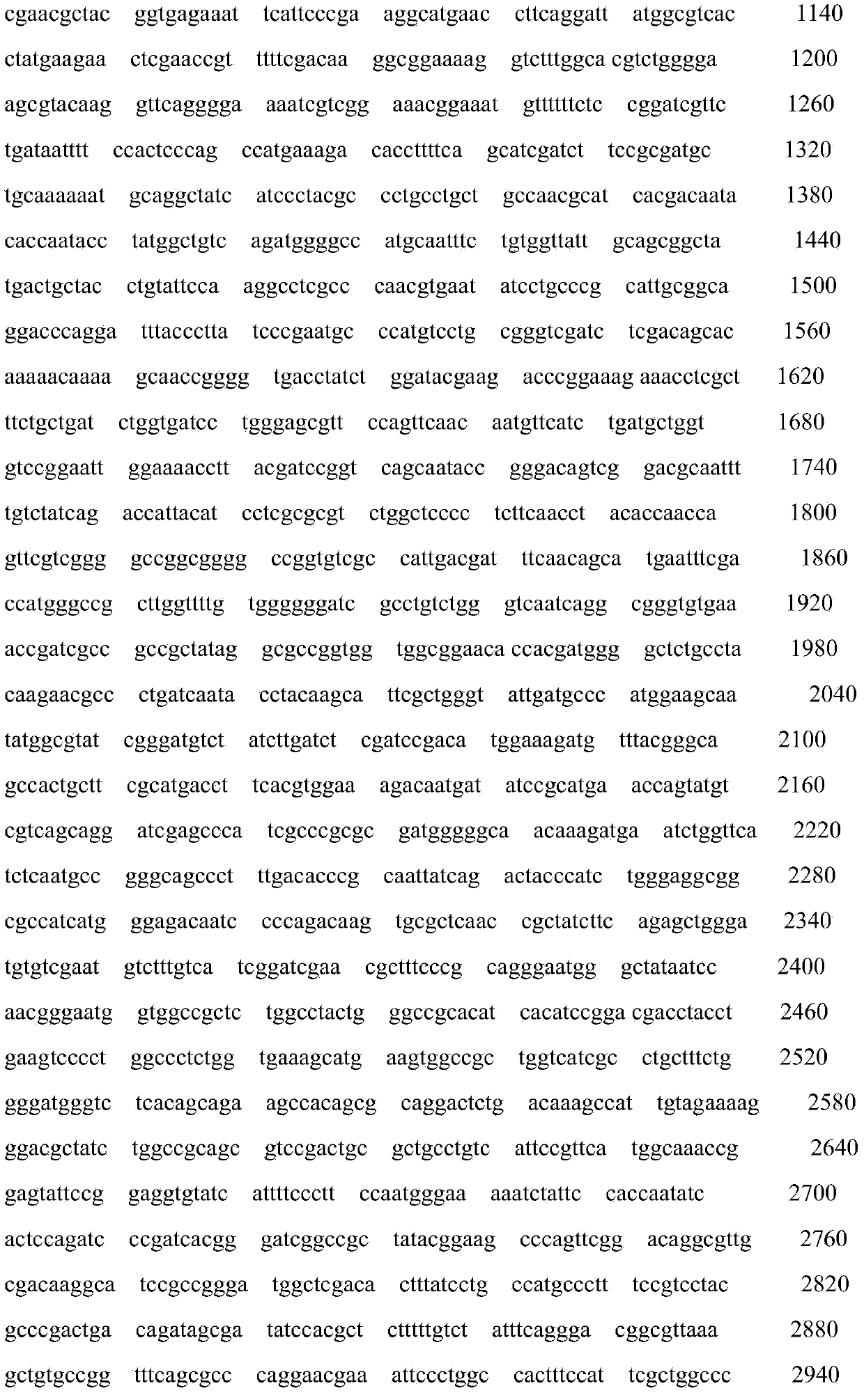

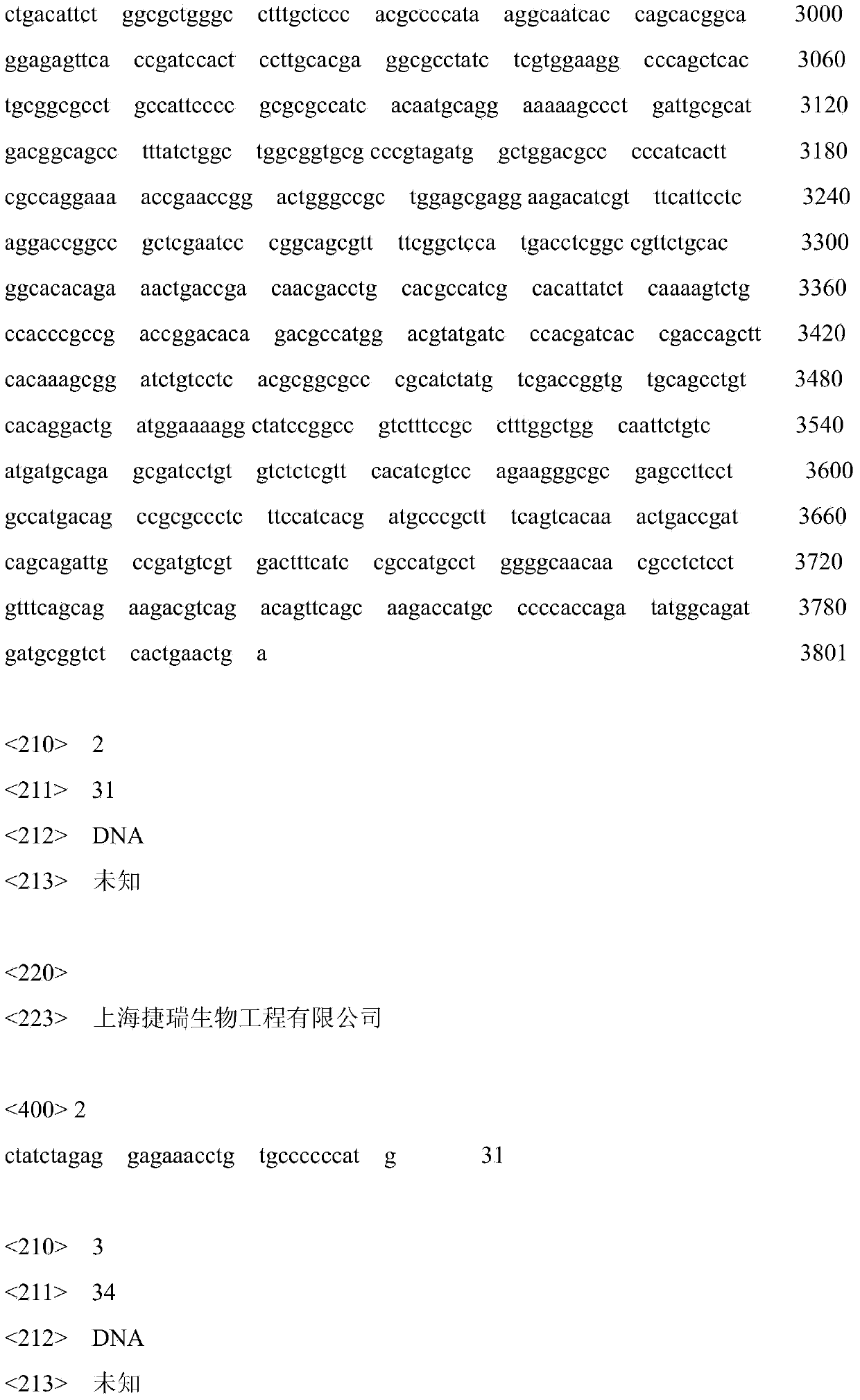

Image

Examples

Embodiment 1

[0041] Transfer the aqueous solution containing 200g / L glucose into a 7L fermenter, add 60g / L resting cells, and react under the conditions of 30°C, air ventilation rate 8L / min, and stirring speed 600rpm, and adjust with 2M NaOH solution during the reaction process. The pH was maintained at 6.0, and the glucose in the supernatant was completely converted in about 21 hours. The yield of 2-KGA (sodium salt) was 97.75%, the concentration could reach 234.6g / L, and the space-time yield was 11.17g / L / h.

Embodiment 2

[0043] Transfer the aqueous solution containing 250g / L glucose into a 7L fermenter, add 60g / L resting cells, and react under the conditions of 30°C, air flow rate 8L / min, stirring speed 600rpm, and adjust with 2M NaOH solution during the reaction process. The pH was maintained at 6.0, and the glucose in the supernatant was completely converted in about 34 hours. The yield of 2-KGA (sodium salt) was 94.74%, the concentration could reach 284.22g / L, and the space-time yield was 8.36g / L / h.

Embodiment 3

[0045] Transfer to an aqueous solution containing 200g / L sodium gluconate in a 7L fermenter, add 30g / L resting cells, and react under the conditions of 30°C, air ventilation 8L / min, and stirring speed 600rpm, and in the supernatant about 15h The conversion of gluconic acid is complete, the concentration of 2-KGA (sodium salt) can reach 198.2g / L, and the space-time yield is 13.2g / L / h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com