Austenitic nonmagnetic steel and balance block

A technology of austenitic and non-magnetic steel, which is applied in the field of stainless steel materials and austenitic non-magnetic steel, can solve the problems of poor processing performance of austenitic high-manganese steel, achieve good wear resistance, not easy to rust, and good The effect of processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

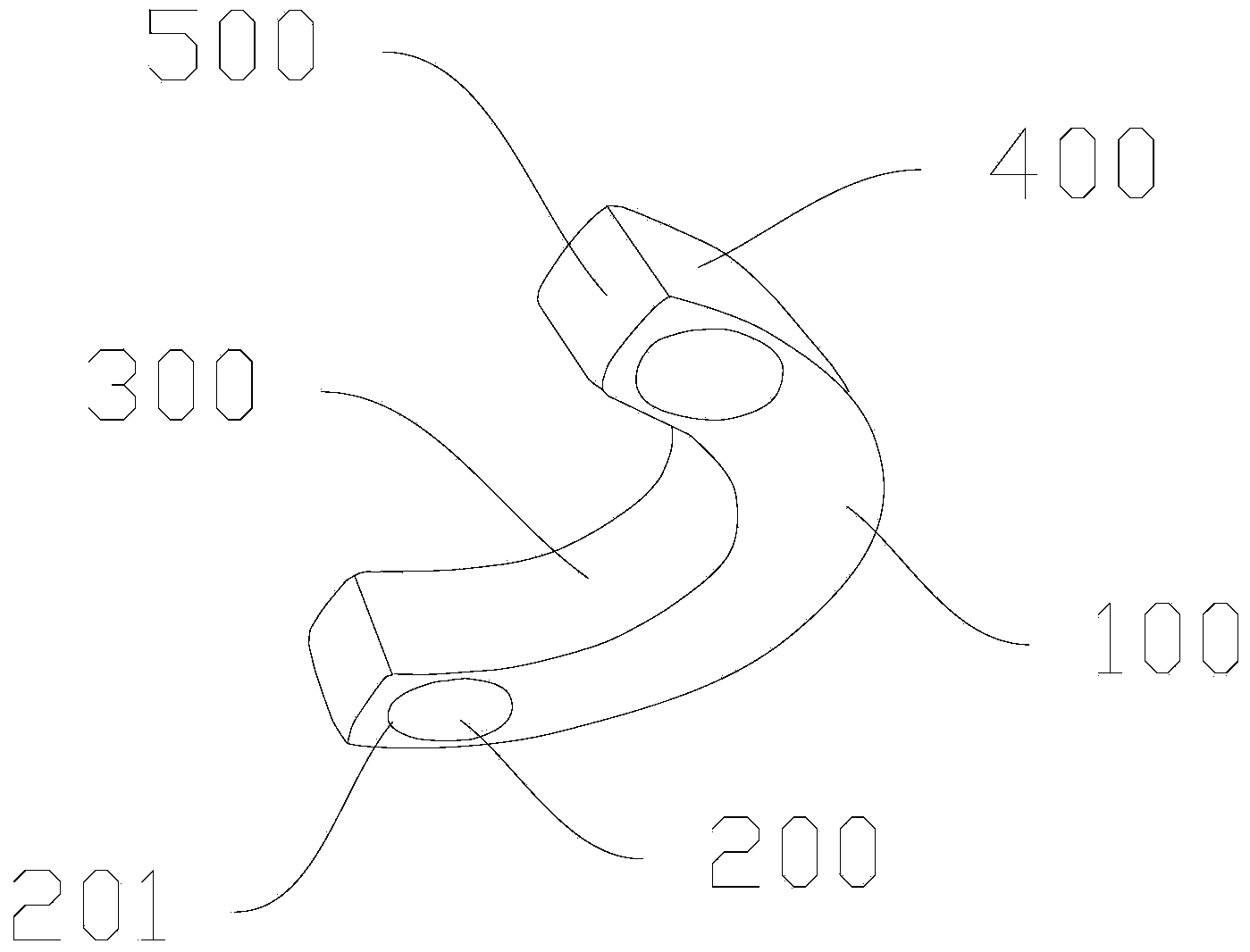

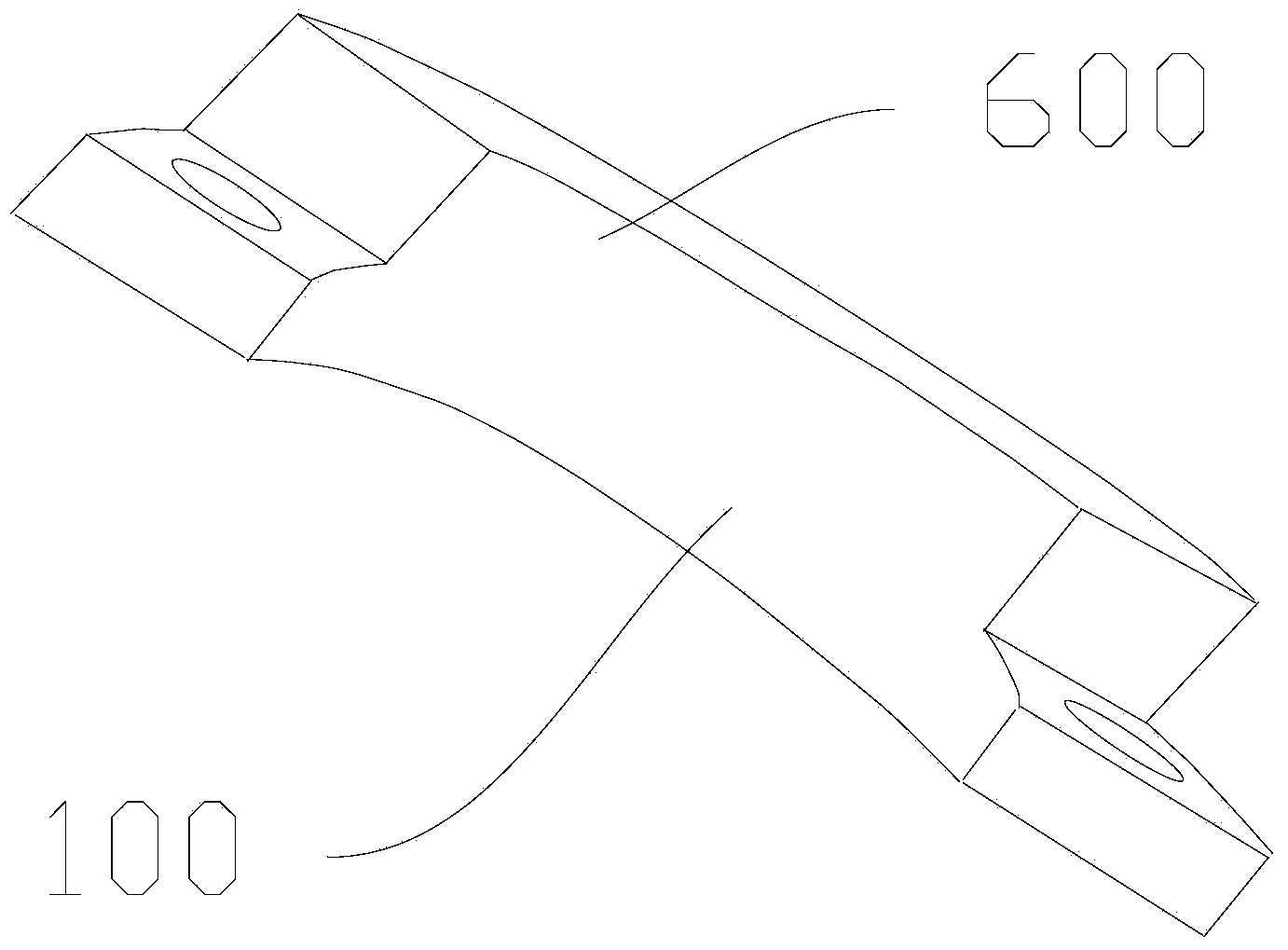

Image

Examples

Embodiment 1

[0018] Austenitic non-magnetic steel, including 0-0.12%wt C, 6-9%wt Cr, 17.5-22.5%wt Mn, 0-1.0%wt Cu, 0.1-1%wt Si, 0- 0.05%wt of S, 0-0.7%wt of Ni and the balance of Fe.

[0019] Optionally, the content of C is 0.1%wt

[0020] Optionally, the Cr content is 8%wt

[0021] Optionally, the Cu content is 0

[0022] Optionally, the Si content is 0.8%wt

[0023] Optionally, the content of S is 0.03%wt

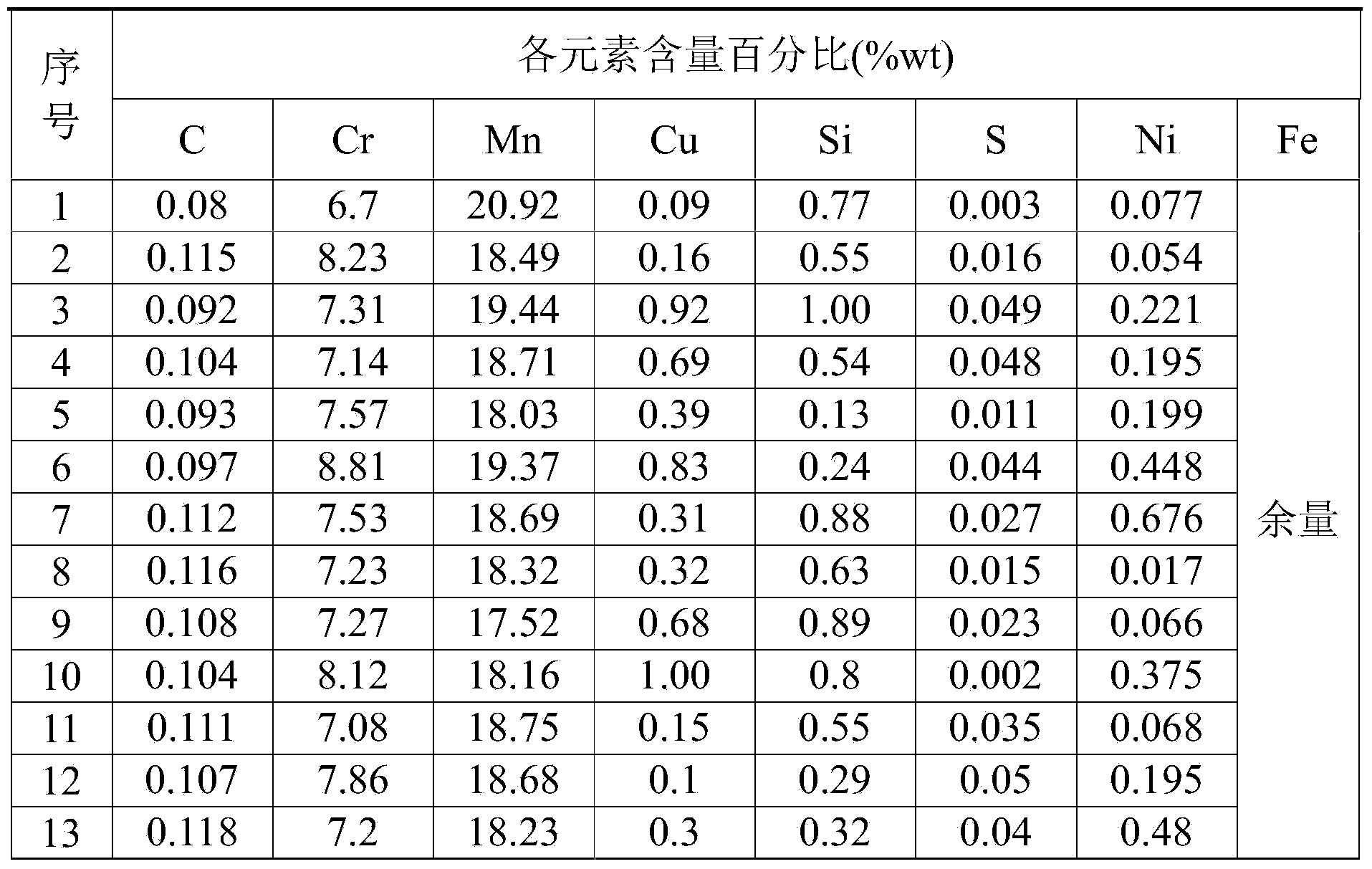

[0024] In order to further verify the performance and effect of the austenitic non-magnetic steel recorded in this embodiment, several examples of the austenitic non-magnetic steel described in this embodiment are specially selected, and the specific element composition is shown in Table 1 below:

[0025] Table 1

[0026]

[0027] Verify the mechanical properties of the austenitic non-magnetic steel recorded in the above table 1: make the austenitic non-magnetic steel recorded in the above table 1 into the specifications requi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| magnetic permeability | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com