Chemical vapor deposition equipment, and method used for cleaning crawler belts in chemical vapor deposition

A chemical vapor deposition and crawler technology, which is applied in gaseous chemical plating, metal material coating process, coating and other directions, can solve the problems of excessive particle contamination, cracking and low efficiency on the surface of the wafer, so as to solve the problem of the wafer surface. Surface particle problem, improve use efficiency, improve the effect of wafer surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Introduced below are some of the various embodiments of the invention, intended to provide a basic understanding of the invention. It is not intended to identify key or critical elements of the invention or to delineate the scope of protection.

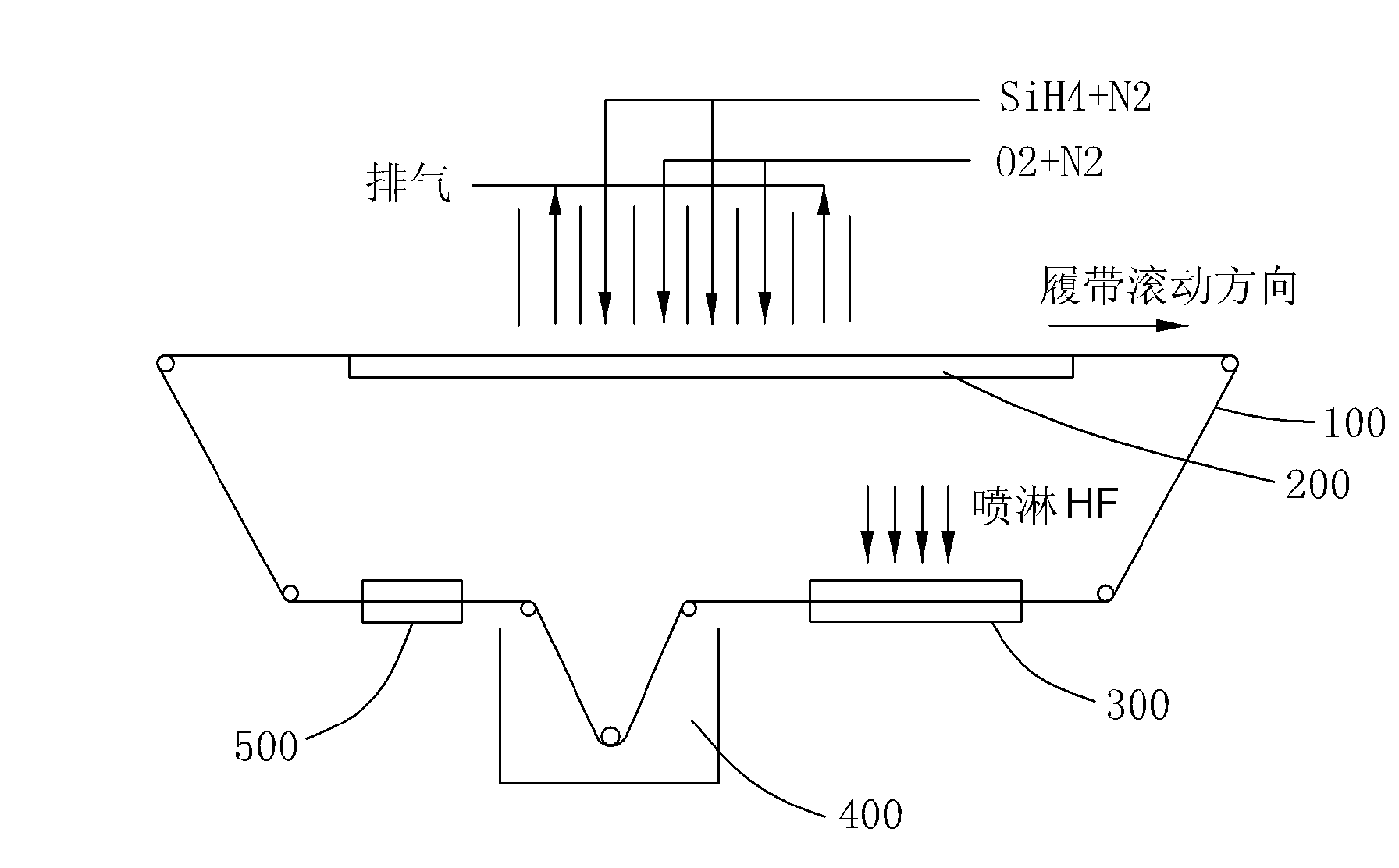

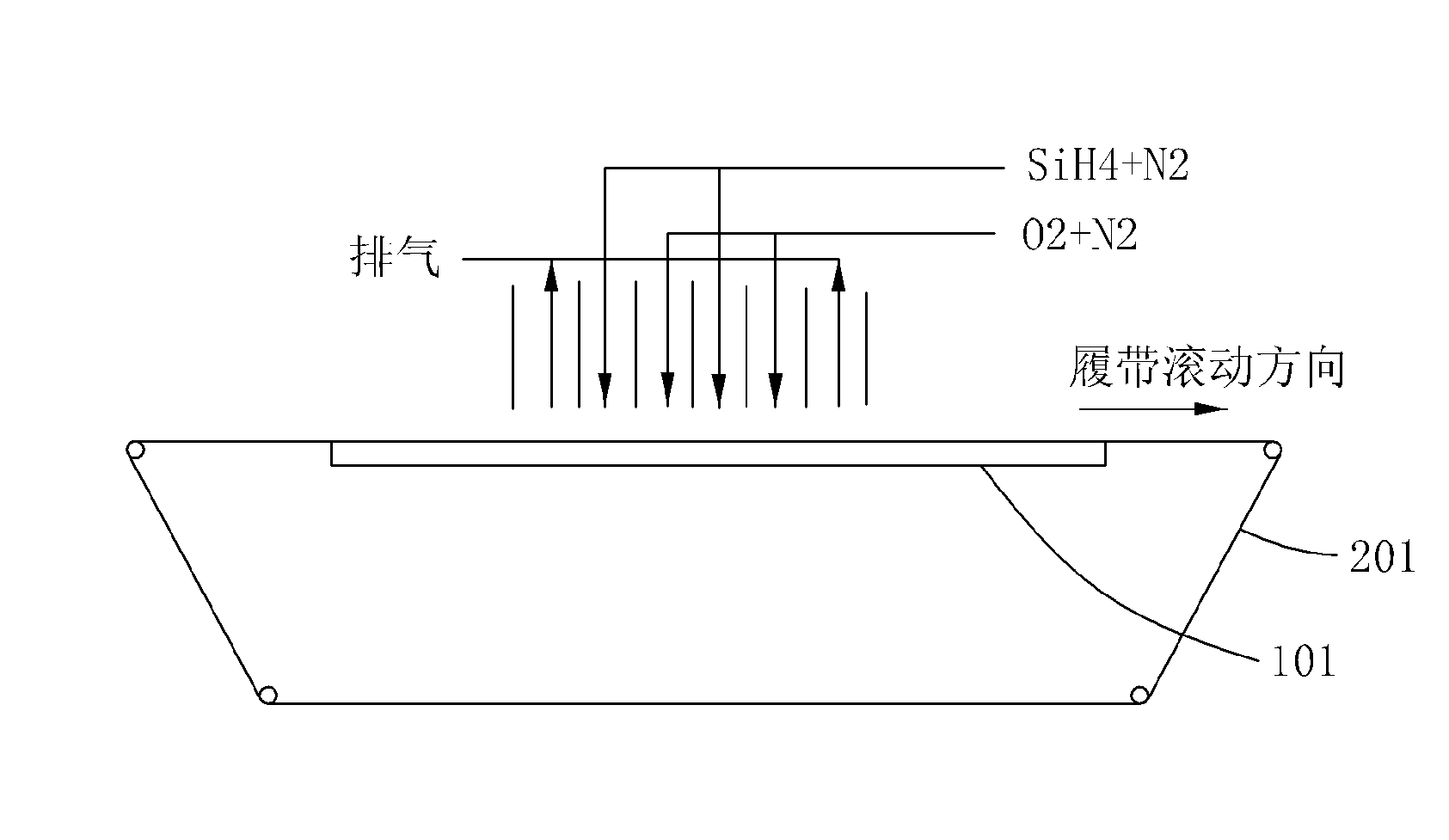

[0028] figure 2 is a schematic diagram showing a chemical vapor deposition apparatus according to an embodiment of the present invention. Refer below figure 2 The chemical vapor deposition apparatus of the present invention will be described.

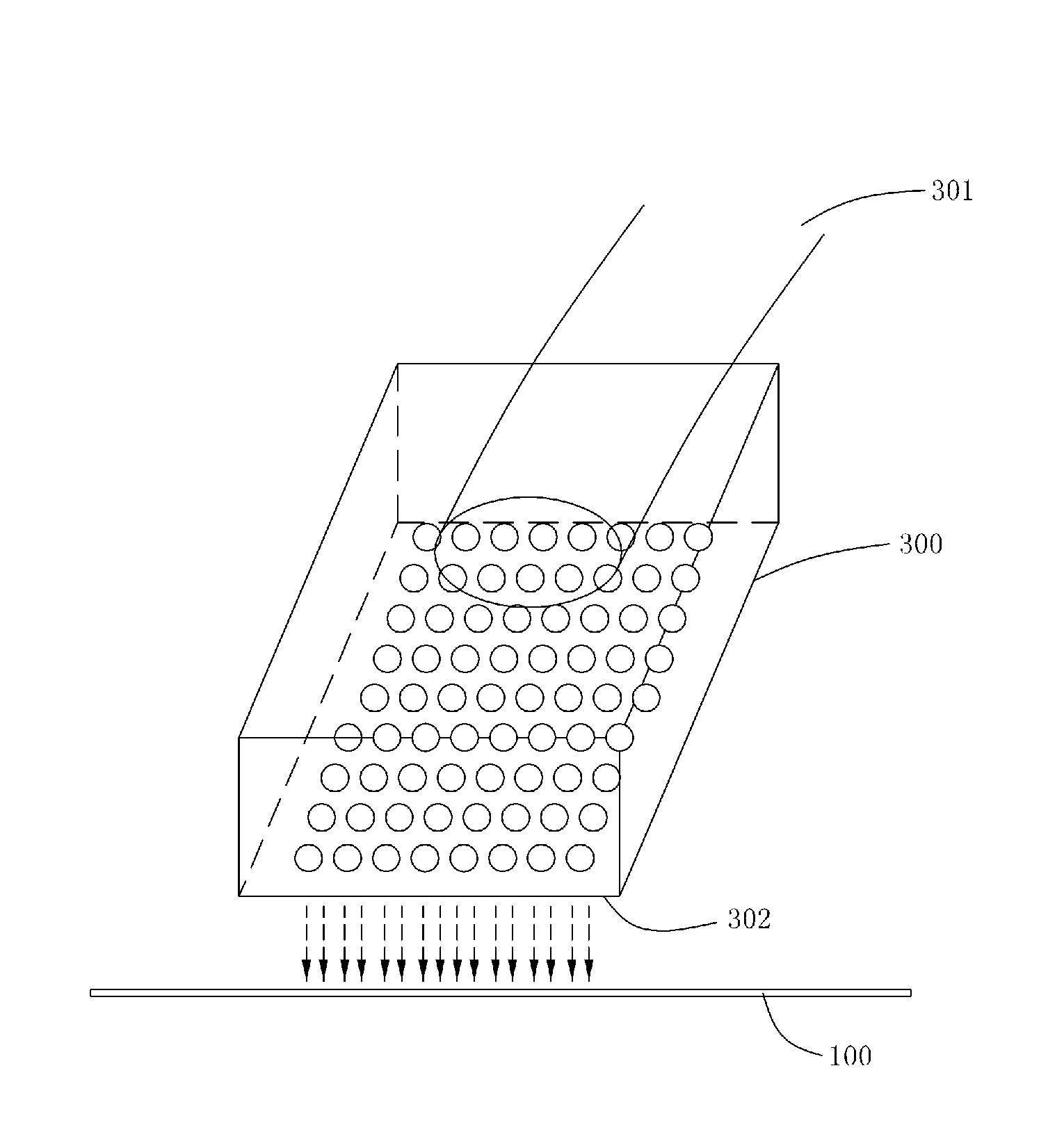

[0029] The chemical vapor deposition equipment of this embodiment includes: a chamber (not shown); an air inlet device (for illustration, only in the figure 2 The table shows the process gas SiH supplied to the chamber 4 and N 2 ); the exhaust device for exporting the treated gas out of the cavity (not shown, only in figure 2 Indicates that the processed O 2 and N 2 export); move the caterpillar 100 on which the disc to be processed is placed; the heating block 200 for heatin...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap