A Cone Cavity High Energy Laser Total Absorption Energy Meter

A technology of high-energy laser and energy meter, which is applied in the direction of using electric radiation detectors for photometry, etc., can solve problems such as the impact of high-energy laser measurement accuracy, achieve the effects of improving test capabilities, reducing escaped energy, and improving measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

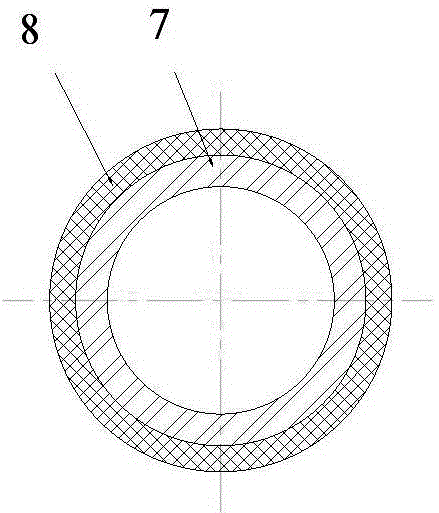

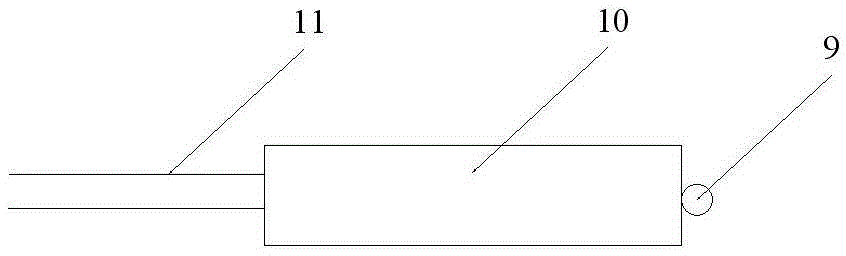

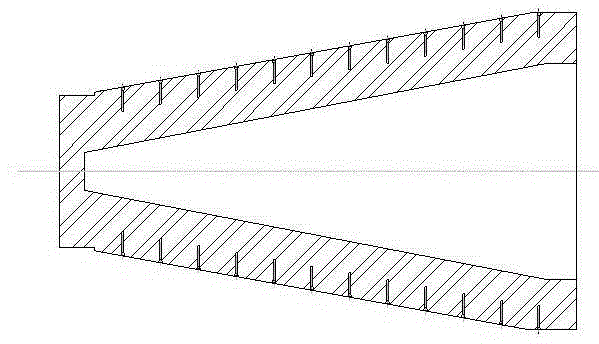

[0024] figure 1 It is the structural representation of the cone cavity type high-energy laser total absorption energy meter of the present invention, figure 2 It is a structural schematic diagram of the heat insulator in the present invention, image 3 It is a schematic structural diagram of a thermocouple sensor in the present invention, and Fig. 4 is a schematic diagram of the arrangement of sink holes on an absorber in the present invention, wherein Fig. 4(a) is a sectional view, Fig. 4(b) is a side view, and Fig. 5 It is a schematic diagram of the V-groove structure of the absorber in the present invention, Fig. 5(a) is a side view, and Fig. 5(b) is a cross-sectional view.

[0025] exist figure 1 ~Among Fig. 5, the conical cavity type high-energy laser total absorption energy meter of the present invention comprises absorber 1, thermocouple sensor 3, absorber support, cylindrical heat insulator 2, data acquisition system 6, shell 5; Wherein , The absorber support inclu...

Embodiment 2

[0037] The structure of this embodiment is the same as that of Embodiment 1, except that in this embodiment, the number of V-shaped grooves is 100, and the included angle θ of the V-shaped grooves is 60°. The counterbores provided on the absorber 1 are arranged equidistantly along the direction of the generatrix of the cone and perpendicular to the direction of the generatrix, and the distance between any two counterbores along the direction of the generatrix of the cone is equal to 6% of the length of the generatrix of the cone of the absorber . The reflecting plate is made of brass material, and the surface of the brass material is gold-plated.

[0038] Fifteen sets of thermocouple sensors are arranged equidistantly in the direction of the generatrix of the cone of the absorber. The diameter of the armored sleeve of the thermocouple sensor is 0.5mm smaller than the diameter of the sink hole on the absorber, and the length of the armored sleeve of the thermocouple sensor is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com