A fluorescent material that eliminates color temperature deviation of white light LEDs

A fluorescent material and LED packaging technology, which is applied in the field of optoelectronics, can solve the problems of poor light color consistency of white LED products, reduce the light efficiency of white light LEDs, and slow down the sedimentation speed, so as to improve the uniformity of light color, reduce the problem of yellow circles, The effect of improving the yield rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

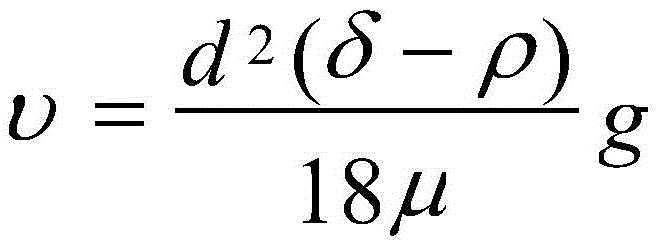

Method used

Image

Examples

Embodiment 1

[0033] This embodiment is to prepare a fluorescent material containing 17 micron YAG yellow phosphor powder and 50 micron silicate hollow glass microspheres, which is used in epoxy resin encapsulation glue.

[0034] First, weigh 10 grams of YAG yellow phosphor powder with a dominant wavelength of 571nm and a central particle size of 17 microns (the specific gravity is 4.5g / cm 3 ), and then weighed 1.1 grams with a specific gravity of 0.7g / cm 3 , and silicate hollow glass microspheres with a central particle diameter of 50 microns, and fully mix the two. The fluorescent material can be combined with epoxy resin glue (the specific gravity is 1.1g / cm 3 ) is used to package white light LEDs with a color temperature between 5700K and 6500K, and the color temperature deviation of the product is not greater than 30K.

Embodiment 2

[0036] This example is to prepare a fluorescent material containing 14 micron YAG yellow phosphor powder and 40 micron silicate hollow glass microspheres, which is used in a silicone resin encapsulant.

[0037] First, weigh 10 grams of YAG yellow phosphor powder with a dominant wavelength of 569nm and a central particle size of 14 microns (the specific gravity is 4.5g / cm 3 ), and then weighed 1.1 grams with a specific gravity of 0.7g / cm 3 , silicate hollow glass microspheres with a central particle diameter of 40 microns, and fully mix the two. The fluorescent material can be combined with silicone resin (specific gravity 1.15g / cm 3 ) for packaging white LEDs with a color temperature between 7000K and 8000K, and the color temperature deviation of the product is not greater than 40K.

Embodiment 3

[0039] This example is to prepare a fluorescent material containing 18 micron YAG orange phosphor powder and 50 micron silicate hollow glass microspheres, which is used for encapsulation of warm white LEDs in combination with silicone resin encapsulation glue.

[0040] First, weigh 10 grams of YAG orange fluorescent powder with a dominant wavelength of 579nm and a central particle size of 18 microns (the specific gravity is 4.5g / cm 3 ), and then weighed 1.1 grams with a specific gravity of 0.70g / cm 3 , and silicate hollow glass microspheres with a central particle diameter of 50 microns, and fully mix the two. The fluorescent material can be combined with silicone resin (specific gravity 1.15g / cm 3 ) is used to package warm white LEDs with a color temperature of about 3300K, and the color temperature deviation of the product is not greater than 20K.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com