Secondary smashing machine for cotton stalks

A secondary crushing and pulverizer technology, applied in agricultural machinery and tools, cutting equipment, applications, etc., can solve the problems of large logistics particle size, unable to meet the processing requirements of cotton wood briquettes, and cotton wood roots cannot be crushed, etc. Achieve the effect of excellent discharge efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

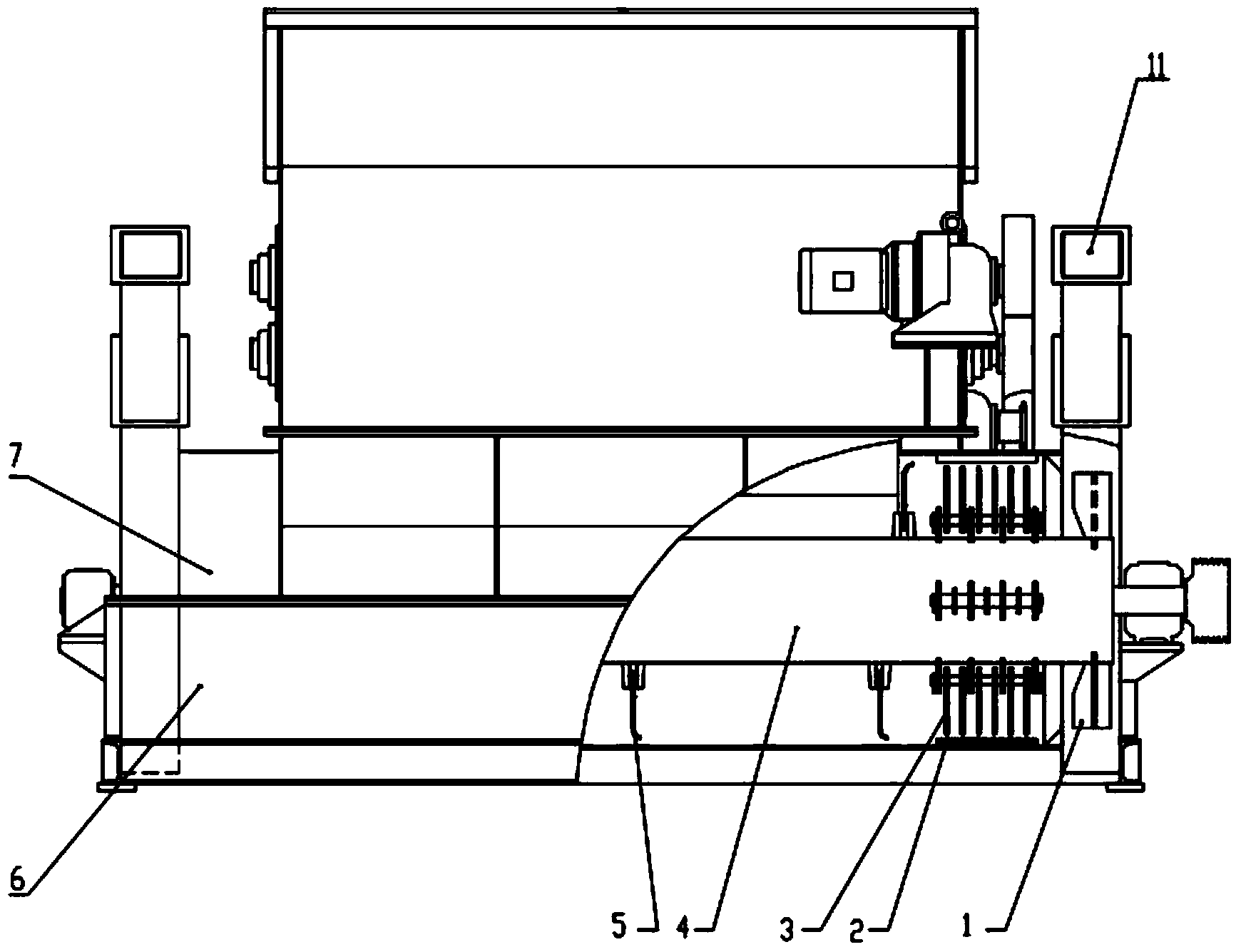

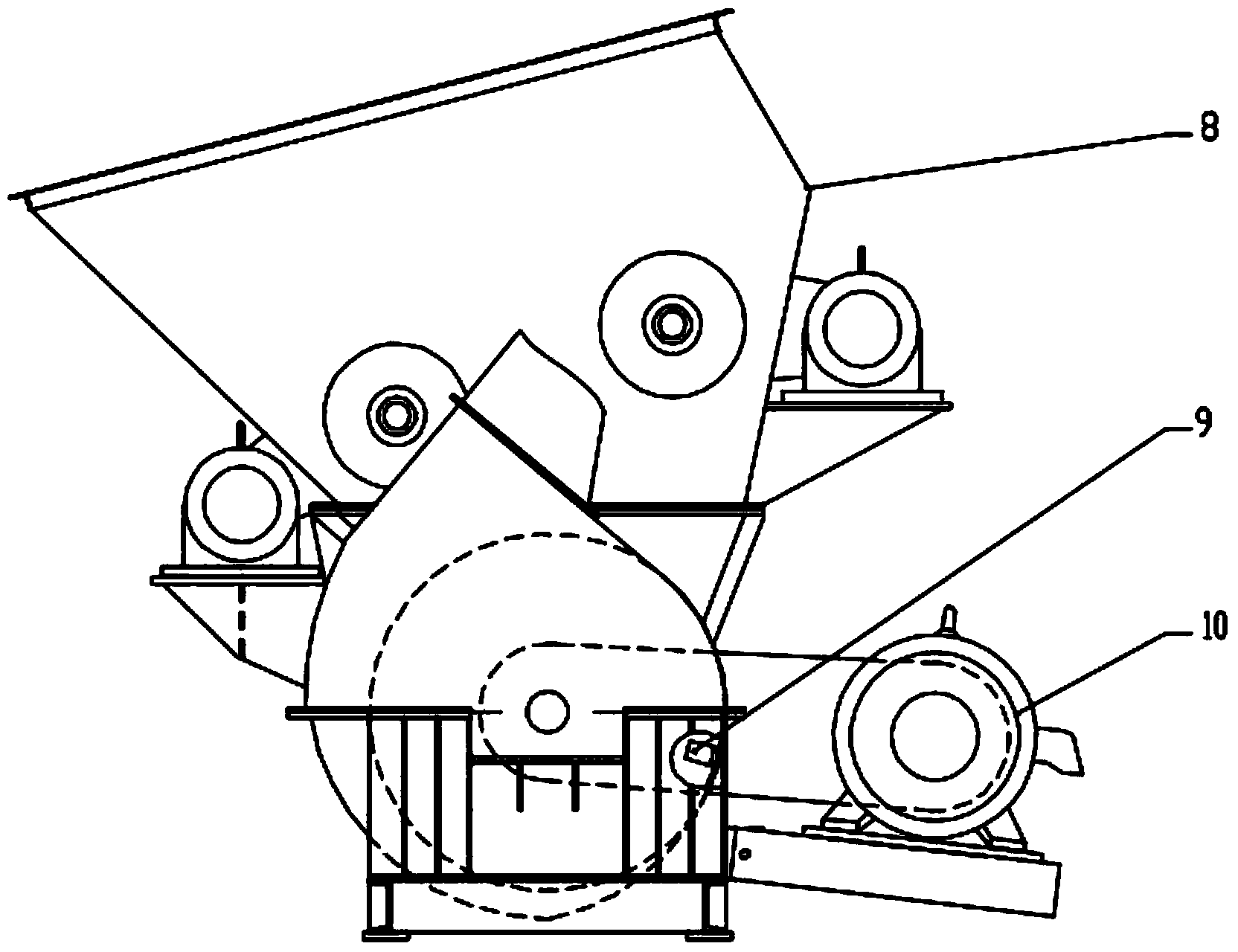

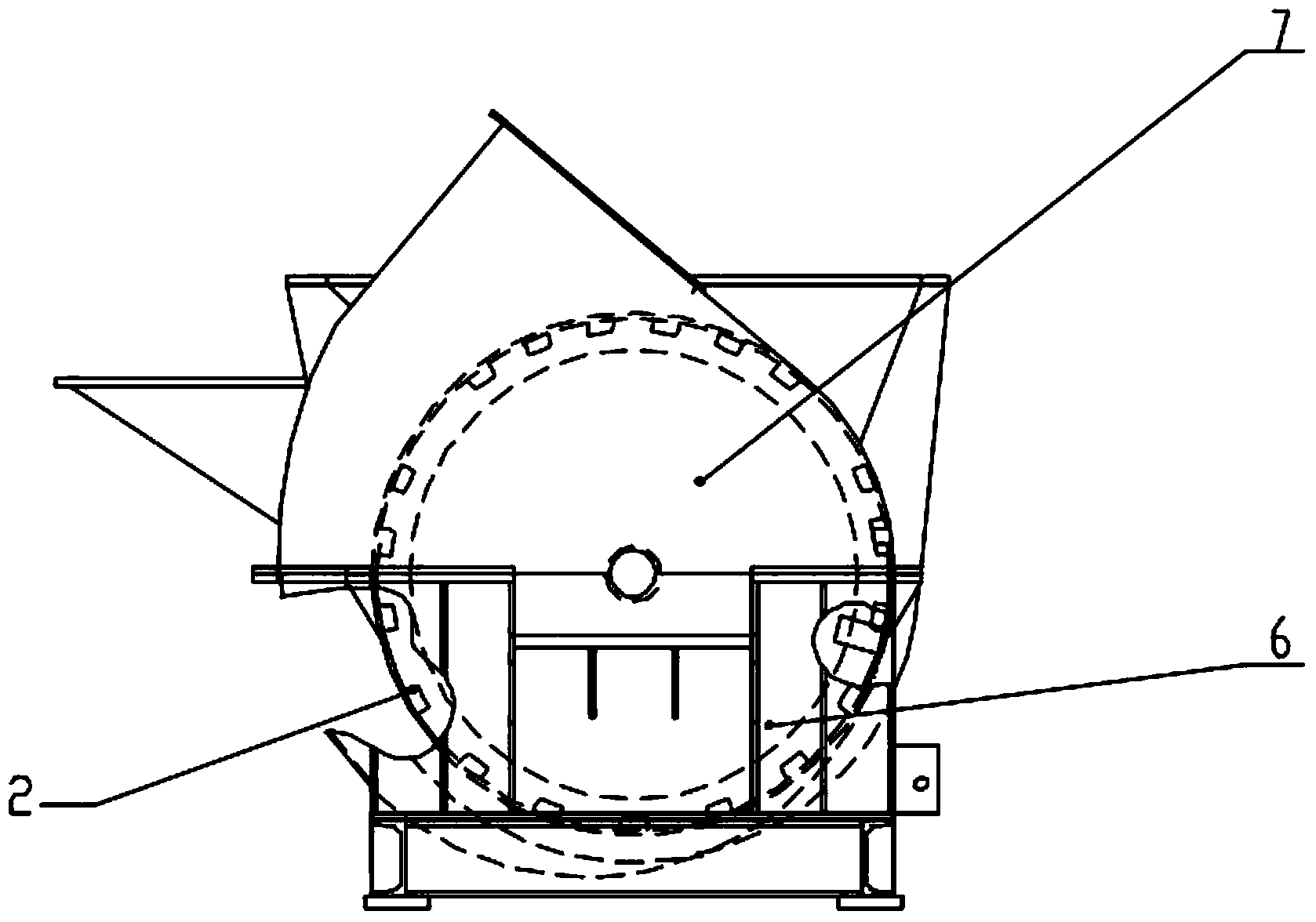

[0033] Such as Figure 1 to Figure 3 As shown, the cotton firewood secondary grinder is mainly composed of an upper shell 7, a lower shell 6, a feeding device 8, a main shaft 4, a fan assembly, a primary crushing mechanism and a secondary crushing mechanism. The bottom of the upper shell 7 and the top of the lower shell 6 are flanged to form a crushing chamber, and the main shaft 4, primary crushing mechanism and secondary crushing mechanism are all installed in the crushing chamber. Feeding device 8 is installed on the top of upper shell 7 by flange, and its inside is communicated with crushing bin. The main shaft 4 is arranged in the crushing bin and is connected with the motor 10 outside the crushing bin, and the motor 10 is installed on the lower shell 6 . A discharge port 11 is also provided on the outer wall of the upper shell 7, and the discharge port communicates with the crushing bin through a discharge channel.

[0034] In this embodiment, the fan components are fa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com