Method for manufacturing high-efficiency full-automatic fish frying device

A production method, fully automatic technology, applied in food preparation, oil/fat baking, food science, etc., can solve the problems of high price, high maintenance cost, short service life, etc., achieve compact structure, simple production method, save production cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

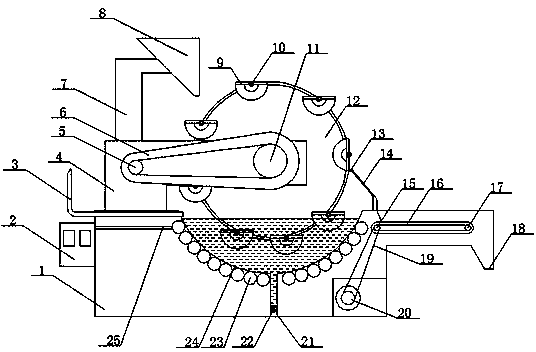

[0023] The present invention will be described below in conjunction with the accompanying drawings. figure 1 It is a structural schematic diagram of the present invention.

[0024]

[0025] A method for manufacturing high-efficiency fully automatic fish frying equipment of the present invention, which comprises the following steps: A. A fryer is arranged on the upper part of the base, the diameter of the upper pot of the fryer is 3m, and stamping equipment is used when the fryer is made on the base , one-time stamping and forming, there are several heating rods arranged in sequence on the outer arc wall of the bottom of the fryer, the diameter of the heating rod is 10cm, the maximum power of a single heating rod is 500w, the adjacent heating rods are connected in series, the left side of the machine base On the upper end of the wall, a temperature control box is welded and fixed. A power line is connected between the temperature control box and the heating rod. An oil discha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com