Preparation method of tea polyphenol nano-liposomes by ethanol injection-dynamic high-pressure microfluidization-enzymolysis

A high-pressure microfluidic, nanoliposome technology, applied in the fields of food, medicine, and cosmetics, can solve the problems of light, oxygen sensitivity, application limitations, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

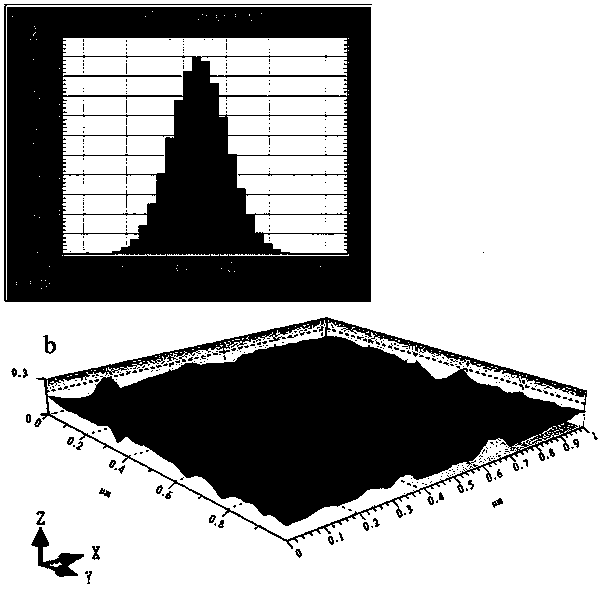

Image

Examples

Embodiment 1

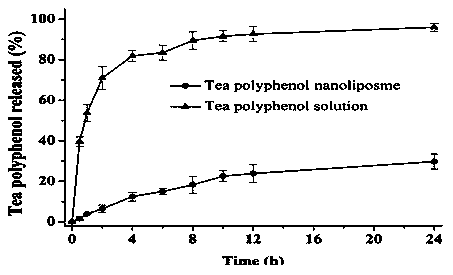

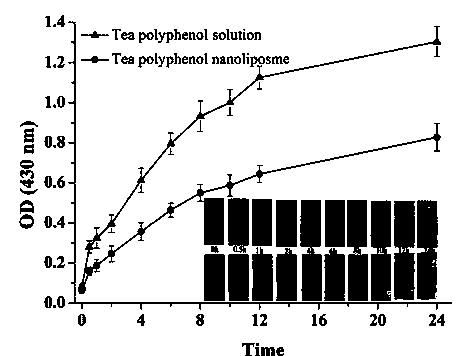

[0020] Weigh 121.2g lecithin, 18.1g cholesterol, 30.6g Tween-80 and 15.0g tea polyphenols, dissolve them completely in 3L absolute ethanol at 45°C, and slowly inject the ethanol solution into 3L phosphate buffer solution (pH = 6.0, 0.05M / L), form an emulsion, then transfer it to a round-bottomed flask, remove absolute ethanol by vacuum rotation under 45°C water bath conditions, and form a uniform suspension that is the crude liposome. The crude liposomes are added into a dynamic high-pressure microjet, and subjected to microfluidization treatment once under the condition of 110 MPa to prepare nanoliposomes. The prepared nano liposome is a relatively transparent milky white solution. The encapsulation efficiency of the prepared tea polyphenol nanoliposomes was 78.6%, the average particle size was 68.5nm, the distribution coefficient was 0.223, and the Zeta potential was -6.86mV. In the in vitro release test, the release of tea polyphenols after 24h The rate is only 29.8%.

Embodiment 2

[0022] Weigh 82.5g lecithin, 10.6g cholesterol, 20.6g Tween-80 and 10.2g tea polyphenols, dissolve them completely in 3L absolute ethanol at 50°C, and slowly inject the ethanol solution into 3L phosphate buffer solution (pH = 6.0, 0.05M / L) to form an emulsion, then transfer it to a round bottom flask, and remove absolute ethanol by vacuum rotation under 45°C water bath conditions, and the formed uniform suspension is the crude liposome. The crude liposomes are added into a dynamic high-pressure microjet, and subjected to microfluidization treatment once under the condition of 110 MPa to prepare nanoliposomes. The prepared nano liposome is a relatively transparent milky white solution. The encapsulation efficiency of the prepared tea polyphenol nanoliposomes was 75.2%, the average particle size was 71.2nm, the distribution coefficient was 0.219, and the Zeta potential was -6.08mV. In the in vitro release test, the release of tea polyphenols after 24h The rate is only 26.8%.

Embodiment 3

[0024] Weigh 182.1g lecithin, 28.4g cholesterol, 46.8g Tween-80 and 22.5g tea polyphenols, dissolve them completely in 3L absolute ethanol at 50°C, and slowly inject the ethanol solution into 3L phosphate buffer solution (pH = 6.0, 0.05M / L), form an emulsion, then transfer it to a round-bottomed flask, remove absolute ethanol by vacuum rotation under 45°C water bath conditions, and form a uniform suspension that is the crude liposome. The crude liposomes are added into a dynamic high-pressure microjet, and subjected to microfluidization treatment once under the condition of 110 MPa to prepare nanoliposomes. The prepared nano liposome is a relatively transparent milky white solution. The encapsulation efficiency of the prepared tea polyphenol nanoliposomes was 82.5%, the average particle size was 65.4nm, the distribution coefficient was 0.232, and the Zeta potential was -5.92mV. In the in vitro release test, the release of tea polyphenols after 24h The rate is only 33.8%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com