Novel spiral classifier lower supporting device

A spiral classifier and support device technology, applied in the direction of solid separation, wet separation, chemical instruments and methods, etc., can solve the problems of damage to the connecting shaft and support, easy wear of the support and shaft, and high failure rate of the classifier. Achieve convenient maintenance, reduce maintenance costs, and reduce downtime

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

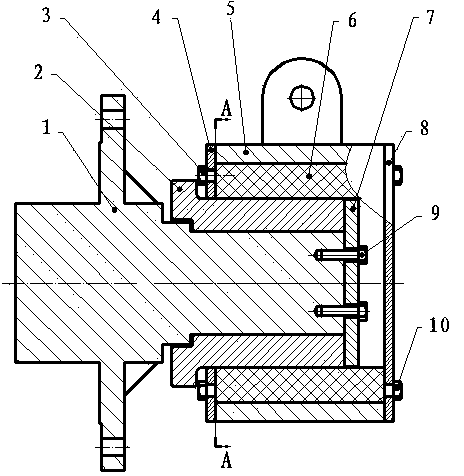

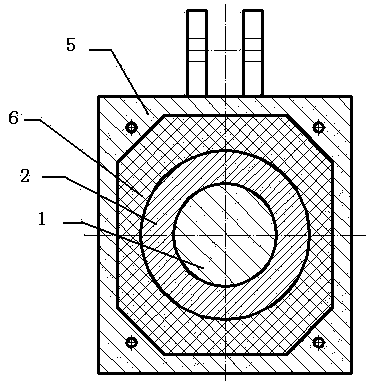

[0013] A new type of lower support device for a spiral classifier, including a shaft head 1 and a lower support body 5, the cavity on the lower support body is square, and a shaft sleeve 2 is installed on the shaft head 1, and a shaft sleeve 2 It is fixed together with the shaft head 1 through the sleeve fixing part 7 and the bolt 9.

[0014] As shown in the figure, the lower shaft head 1 is equipped with a shaft sleeve 2, the shaft head 1 and the shaft sleeve 2 are fixed by the shaft sleeve fixing part 7 and the shaft sleeve 2, and the shaft head 1 and the shaft sleeve 2 are limited. The relative radial and axial movement; the cavity of the lower support base 5 and the shaft head 1 on which the sleeve 2 is installed is filled with wear-resistant packing 6, and the lower shaft head 1 is in the wear-resistant packing 6 relative to the cavity Rotational movement; the packing gland with holes 4 and the packing gland with blind holes 8 are installed and fixed on the lower supporti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com